High-selectivity fuel adsorption and desulfurization agent of bamboo source porous biomass carbon

A high-selectivity, adsorption desulfurization technology, applied in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of desulfurization selectivity, commercial fuel desulfurization efficiency, etc. The effect of group improvement and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

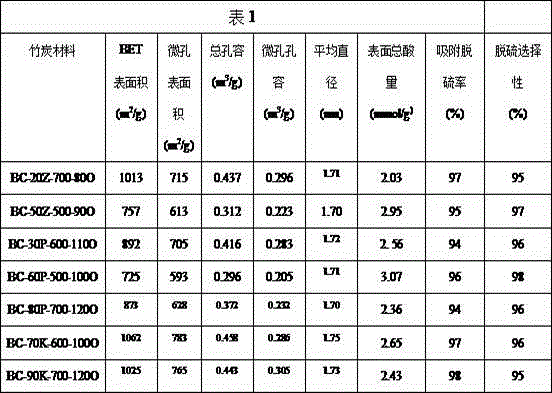

[0019] Example 1: Weigh 6g of bamboo powder into a beaker, and weigh 20% ZnCl of the amount of bamboo powder 2 Dissolve with deionized water, and add a few drops of concentrated hydrochloric acid to make the solution clear, then put the solution into a beaker containing bamboo powder, stir the bamboo powder evenly, soak it at room temperature for 12 hours, and then add 40 o Bake in the vacuum oven of C for 12 hours, take it out and add it to the quartz glass tube, in a tube furnace at 700 o Sintered at C for 2 h, cool to room temperature naturally, take out the material and wash with deionized water, pickling, and water until the filtrate is neutral. Put the obtained material into 110 oC Dry in an oven for 8 hours. Weigh 1.5g of the above bamboo source porous biochar, treat it with 9ml of 65% nitric acid at 80°C for 8 hours, wash it with distilled water until the filtrate is neutral, and then dry it in an oven at 110°C for 8 hours. The material is denoted as BC-20Z-700-80O. The...

Embodiment 2

[0020] Example 2: Weigh 8g of bamboo powder into a beaker, weigh 50% of the amount of ZnCl of the bamboo powder 2 Dissolve with deionized water, and add a few drops of concentrated hydrochloric acid to make the solution clear, then add the solution to a beaker containing bamboo powder, stir the bamboo powder evenly, soak it at room temperature for 18 hours, and then add 60 o Bake in the vacuum oven of C for 8 hours, take it out and put it into a quartz glass tube, in a tube furnace under a nitrogen atmosphere at 500 o Sintered at C for 3 h, cool to room temperature naturally, take out the material and wash with deionized water, pickling, and water until the filtrate is neutral. Put the obtained material into 110 oC Dry in an oven for 10 hours. Weigh 2g of bamboo source porous biochar and treat it with 12 ml of 65% nitric acid at 90°C for 3 hours, wash it with distilled water until the filtrate is neutral, and then dry it in an oven at 110°C for 9 hours. The material is denoted ...

Embodiment 3

[0021] Example 3: Weigh 10g of bamboo powder into a beaker, weigh 30% of the amount of bamboo powder and dissolve phosphoric acid in deionized water, then add the solution to a beaker containing bamboo powder, stir the bamboo powder evenly, and place it at room temperature. Soak for 20h, then add 50 o Bake in the vacuum oven of C for 10 hours, take it out and put it into a quartz glass tube, in a tube furnace under a nitrogen atmosphere at 600 o Sintered at C for 3 h, cool to room temperature naturally, take out the material and wash with deionized water, pickling, and water until the filtrate is neutral. Put the obtained material into 110 oC Dry in an oven for 10 hours. Weigh 4g of bamboo source porous biochar, treat it with 24ml of 65% nitric acid at 110°C for 4h, wash it with distilled water until the filtrate is neutral, and then dry it in an oven at 110°C for 10h. The material is denoted as BC-30P-600-110O. The pore structure parameters, total surface acid content, adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com