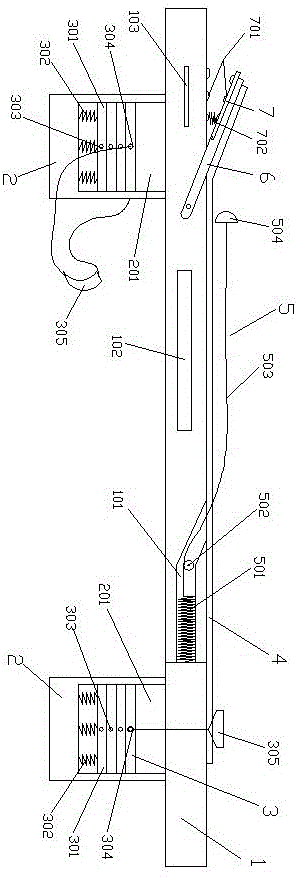

Comprehensive abdominal muscle training device

A comprehensive training and abdominal muscle technology, applied in the direction of muscle training equipment, elastic resistance devices, sports accessories, etc., can solve the problems of inconspicuous movement effects, affecting the efficiency of exercise, and difficult exercise movements, etc., to achieve improved wear resistance and Strength, improve compressive strength, improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]According to weight ratio, this polyurethane foam material is made of 200 parts of polyester polyols, 190 parts of polyisocyanate, 40 parts of cyclohexane, 5 parts of dibutyltin dilaurate, 7 parts of isopropyl azodicarboxylate, 8 parts The buffering agent of one part and the composite additive of 3 parts are mixed and formed, wherein, the buffering agent is made of sepiolite wool, modified glass microspheres and ethyl orthosilicate with the weight ratio of 10:6:34, and the composite additive is Nanocrystalline boehmite, ammonium fluoride, boric acid, elemental silicon powder, magnesium borate whiskers and an organic reinforcing agent are prepared in a ratio of 10:0.5:0.5:5:3:6; the organic reinforcing agent is bisphenol F Type epoxy resin, hydrogenated bisphenol A type epoxy resin, bisphenol S type epoxy resin, modified nano-silica and modified silica sol are prepared in a weight ratio of 6:5:4:2:3, so Described modified nano silicon dioxide and modified glass microspher...

Embodiment 2

[0053] According to weight ratio, this polyurethane foam material is made of 220 parts of polyester polyols, 210 parts of polyisocyanate, 46 parts of cyclohexane, 7 parts of dibutyltin dilaurate, 9 parts of isopropyl azodicarboxylate, 10 parts The buffering agent of one part and the composite additive of 5 parts are mixed and formed, wherein, the buffering agent is made of sepiolite wool, modified glass microspheres and ethyl orthosilicate with the weight ratio of 12:8:38, and the composite additive is Nanocrystalline boehmite, ammonium fluoride, boric acid, elemental silicon powder, magnesium borate whiskers and an organic reinforcing agent are prepared in a ratio of 12:0.5:0.5:6:4:8; the organic reinforcing agent is bisphenol F Type epoxy resin, hydrogenated bisphenol A type epoxy resin, bisphenol S type epoxy resin, modified nano-silica and modified silica sol are prepared in a weight ratio of 6:5:4:2:3, so Described modified nano-silica and modified glass microspheres are ...

Embodiment 3

[0058] According to weight ratio, this polyurethane foam material is made of 210 parts of polyester polyols, 200 parts of polyisocyanates, 43 parts of cyclohexane, 6 parts of dibutyltin dilaurate, 8 parts of isopropyl azodicarboxylate, 9 parts 4 parts of buffering agent and 4 parts of composite additives, wherein the buffering agent is made of sepiolite wool, modified glass microspheres and tetraethyl orthosilicate with a weight ratio of 11:7:36, and the composite additives are Nanocrystalline boehmite, ammonium fluoride, boric acid, elemental silicon powder, magnesium borate whiskers and an organic reinforcing agent are prepared in a ratio of 11:0.5:0.5:5.5:3.5:7; the organic reinforcing agent is bisphenol F Type epoxy resin, hydrogenated bisphenol A type epoxy resin, bisphenol S type epoxy resin, modified nano-silica and modified silica sol are prepared in a weight ratio of 6:5:4:2:3, so Described modified nano silicon dioxide and modified glass microspheres are obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com