Environmental-friendly styrene-acrylic emulsion for automotive air filtration paper

A technology of styrene-acrylic emulsion and air filter paper, which is applied in the direction of filter paper, paper, papermaking, etc., to achieve the effects of good water resistance, flexible film and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

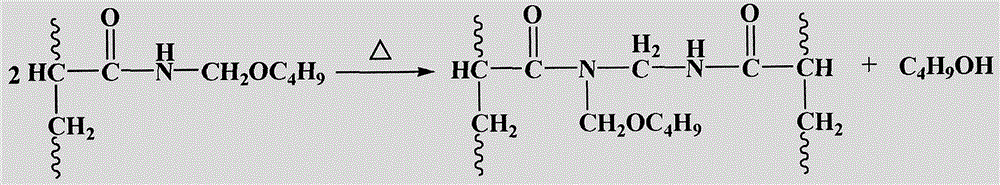

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of environment-friendly type styrene-acrylic emulsion, and the method comprises the following steps:

[0023] (1) Styrene, corresponding acrylic acid derivatives, environment-friendly self-crosslinking monomer, sodium dodecylbenzenesulfonate and emulsifier are dispersed in water to prepare a pre-emulsion;

[0024] (2) The above-obtained pre-emulsion and sodium persulfate aqueous solution were added dropwise to an aqueous solution containing surfactant, emulsifier, sodium persulfate and sodium bicarbonate, and reacted at a certain temperature for a period of time to obtain a blue emulsion.

[0025] The present invention has no special requirements on the amount of emulsifiers such as styrene, acrylic acid derivatives and sodium dodecylbenzenesulfonate in step (1), as long as a pre-emulsion with excellent performance can be prepared.

[0026] The acrylic acid derivative described in the step (1) of the present invention ...

Embodiment 1

[0045] Example 1: Used to illustrate the emulsion and its preparation method

[0046] 1. Pre-emulsification stage

[0047]Dissolve 1.2g of sodium lauryl sulfate and 1.2g of emulsifier OP-15 in 90ml of deionized water, stir rapidly for 5 minutes and slowly add 150.0g of styrene, 75.0g of methyl methacrylate, 75.0g of n-acrylic acid Butyl ester, 3.0 g of acrylic acid, 3.0 g of methacrylic acid, and 5.0 g of N-isobutoxymethacrylamide were all added and then stirred for 30 minutes to obtain a pre-emulsion.

[0048] 2. Main reaction stage

[0049] In a multi-necked flask with a capacity of 1000ml equipped with a stirrer, condenser, dropping funnel and thermometer, put 0.8g sodium lauryl sulfate, 0.8g emulsifier OP-15, 0.8g sodium persulfate and 1.5g carbonic acid Dissolve sodium hydrogen in 150ml of deionized water, stir and heat up to 80°C; add 8% pre-emulsion, control the temperature at 78-82°C, react for 1h until the emulsion turns blue; add the remaining pre-emulsion dropwise...

Embodiment 2

[0055] 1. Pre-emulsification stage

[0056] Dissolve 1.2g of sodium dodecylbenzenesulfonate and 1.5g of emulsifier OP-10 in 90ml of deionized water, stir rapidly for 5 minutes, then slowly add 180.0g of styrene, 75.0g of methyl acrylate, and 45.0g of propylene acrylate Esters, 6.0g of acrylic acid, 5.0g of N-isobutoxymethacrylamide were all added and then stirred for 30min to obtain a pre-emulsion.

[0057] 2. Main reaction stage

[0058] In a multi-necked flask with a capacity of 1000ml equipped with a stirrer, a condenser, a dropping funnel and a thermometer, put 1.0g sodium dodecylbenzenesulfonate, 0.8g emulsifier OP-10, 0.8g sodium persulfate and 1.5 Dissolve g sodium bicarbonate in 150ml of deionized water, stir and heat up to 80°C; add 10% pre-emulsion, control the temperature at 78-82°C, and react for 1h until the emulsion is blue; the rest of the pre-emulsion is at a constant speed for about 4h After the dropwise addition was completed, 1.6 g of sodium persulfate aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com