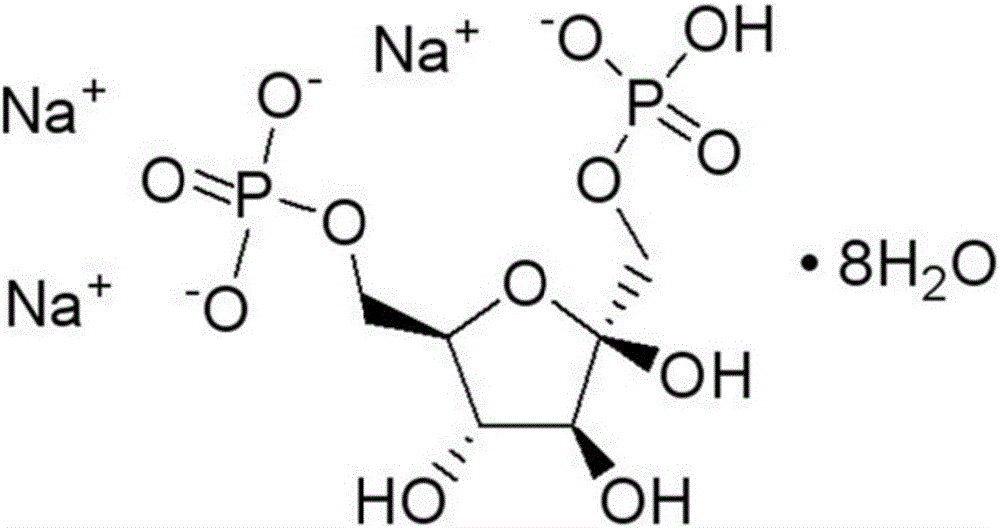

Fructose diphosphate compound and preparation method thereof

A technology of sodium fructose diphosphate and compounds, which is applied in the field of medicine, can solve the problems that cannot reflect the contribution of the new crystallization process safety, and achieve good anti-microbial erosion ability, increased safety, and low hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

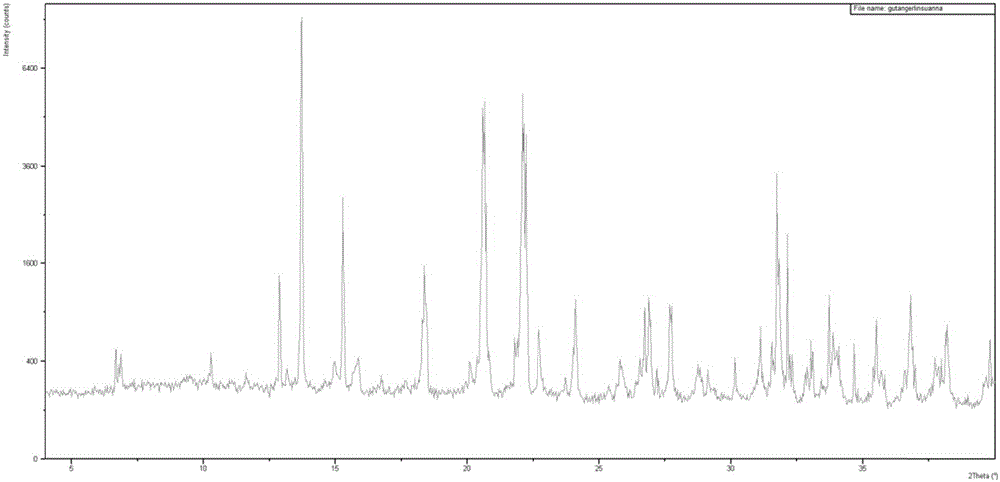

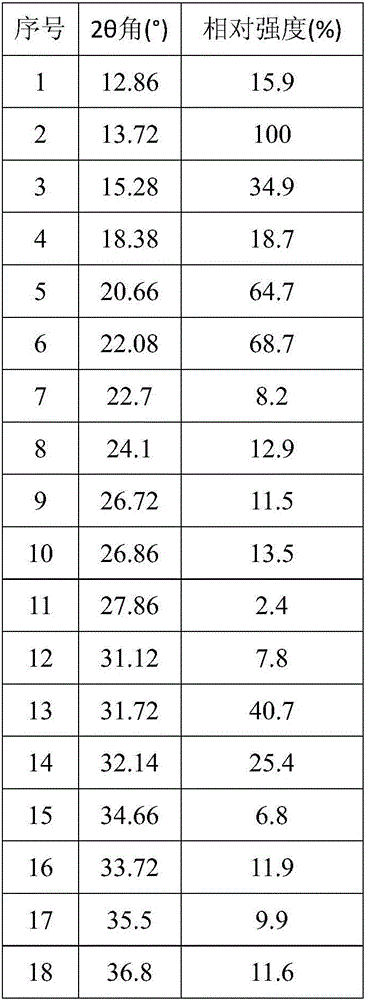

Image

Examples

Embodiment 1

[0053] In parts by weight, the raw materials selected in this embodiment include:

[0054]

[0055] The preparation method is as follows:

[0056] (1) Add the above-mentioned raw materials into the reactor, and react for 10 hours at a pH of 6.0 and a temperature of 37° C.;

[0057] (2) the product of the reaction described in step (1) is filtered through a ceramic membrane, and the filtrate is collected;

[0058] (3) The filtrate described in step (2) is passed through 732 cation exchange resins, after diluting the effluent with deionized water, it is adsorbed by 717 anion exchange resins, after using lye to remove miscellaneous ions, elute with sodium chloride solution, get eluent;

[0059] (4) Concentrate the eluate described in step (3) by nanofiltration, and when the concentration of the solution reaches 35%, add activated carbon for needle decolorization to the solution and filter and adjust the pH to 6.0 to obtain a concentrated solution;

[0060] (5) Add ethanol t...

Embodiment 2

[0064] In parts by weight, the raw materials selected in this embodiment include:

[0065]

[0066] The preparation method is as follows:

[0067] (1) Put the above-mentioned raw materials into the reactor, and react for 8.5 hours under the conditions of pH 6.0 and temperature 37°C;

[0068] (2) the product of the reaction described in step (1) is filtered through a ceramic membrane, and the filtrate is collected;

[0069] (3) The filtrate described in step (2) is passed through 732 cation exchange resins, after diluting the effluent with deionized water, it is adsorbed by 717 anion exchange resins, after using lye to remove miscellaneous ions, elute with sodium chloride solution, get eluent;

[0070] (4) Concentrate the eluate described in step (3) by nanofiltration, and when the concentration of the solution reaches 35%, add activated carbon for needles to the solution for decolorization, filter and adjust the pH to 5.3 to obtain a concentrated solution;

[0071] (5) A...

Embodiment 3

[0075] In parts by weight, the raw materials selected in this embodiment include:

[0076]

[0077]

[0078] The preparation method is as follows:

[0079] (1) Add the above-mentioned raw materials into the reactor, and react for 8 hours under the conditions of pH 6.0 and temperature 37°C;

[0080] (2) the product of the reaction described in step (1) is filtered through a ceramic membrane, and the filtrate is collected;

[0081] (3) The filtrate described in step (2) is passed through 732 cation exchange resins, after diluting the effluent with deionized water, it is adsorbed by 717 anion exchange resins, after using lye to remove miscellaneous ions, elute with sodium chloride solution, get eluent;

[0082] (4) Concentrate the eluate described in step (3) by nanofiltration, and when the concentration of the solution reaches 37%, add activated carbon for needles to the solution for decolorization, filter and adjust the pH to 4.0 to obtain a concentrated solution;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com