Manufacturing method for opening pulling copper pipe

A manufacturing method and technology for copper tubes, which are applied in the field of manufacturing copper tubes with pull openings, can solve the problems of low degree of automation, difficult manufacturing methods and processing techniques, differences in specific taper angles and large and small apertures, etc., and achieve a high degree of automation and processing methods. Feasible, low production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

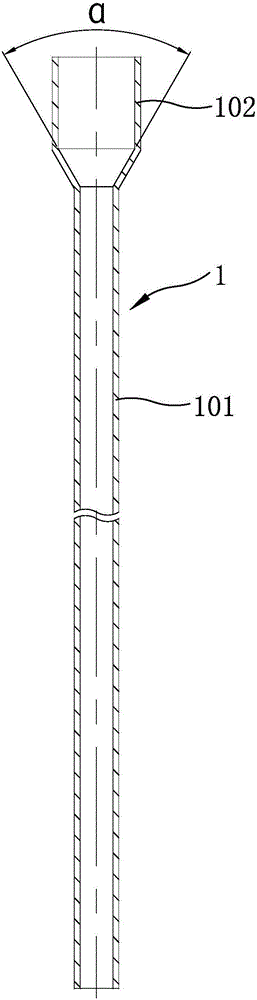

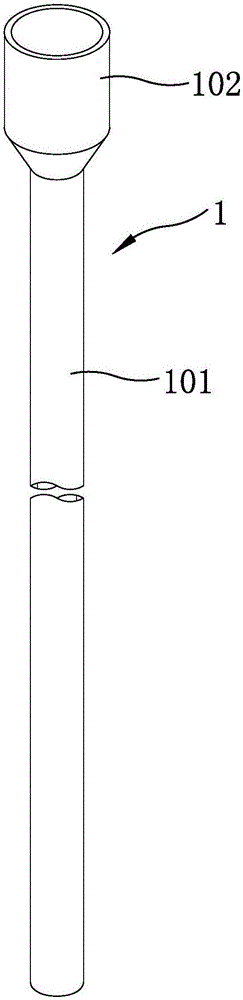

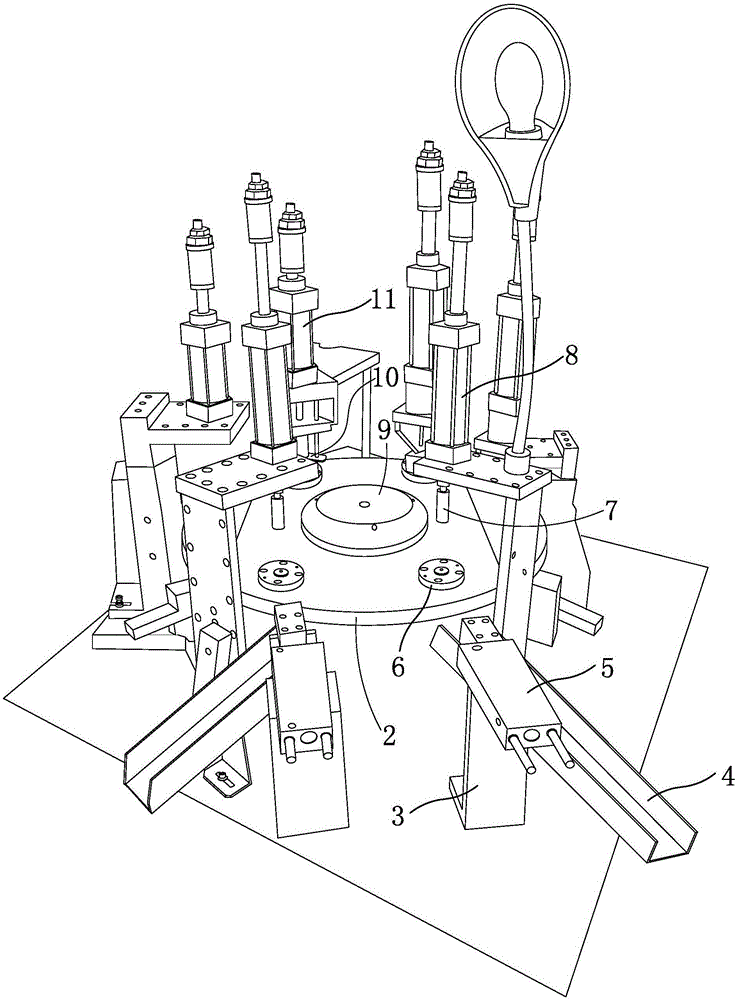

[0016] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. like figure 1 , figure 2 As shown, the material of the copper tube is phosphorus deoxidized copper tube for air conditioning and refrigeration industry, Φ6.35mm, wall thickness 0.5mm, chemical composition: copper silver Cu+Ag99.9%, boron P0.015~0.040%, mechanical properties : Tensile strength (Rm) 220MPa-260MPa, elongation (%) ≥ 30, Vickers hardness HV ≤ 70. Main features: Good welding performance and cold bending performance, generally no "hydrogen disease" tendency, processed and used in reducing atmosphere, not suitable for processing and used in oxidizing atmosphere; good electrical conductivity, thermal conductivity, corrosion resistance and processing performance, suitable for Welding and brazing. At the same time, it contains less impurities that reduce electrical conductivity and thermal conductivity, and a trace amount of oxygen has l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com