Preparation method of low-temperature plasma modified Mo-TiO2 photocatalyst

A low-temperature plasma and photocatalyst technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve problems such as poor stability, deactivation, and low catalytic activity. Achieve the effects of promoting separation, narrow band gap, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

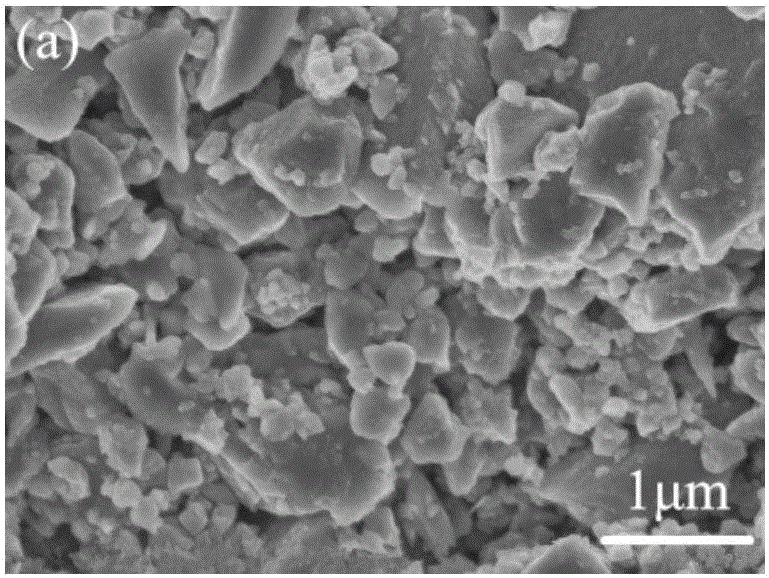

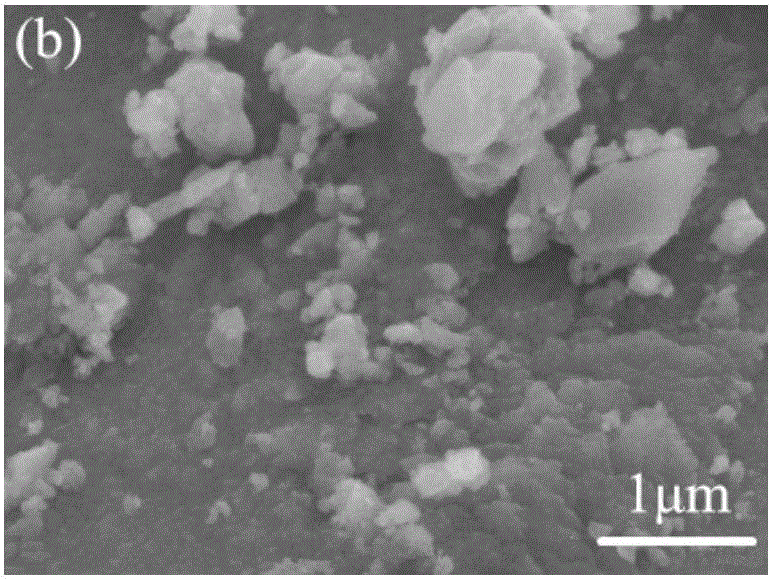

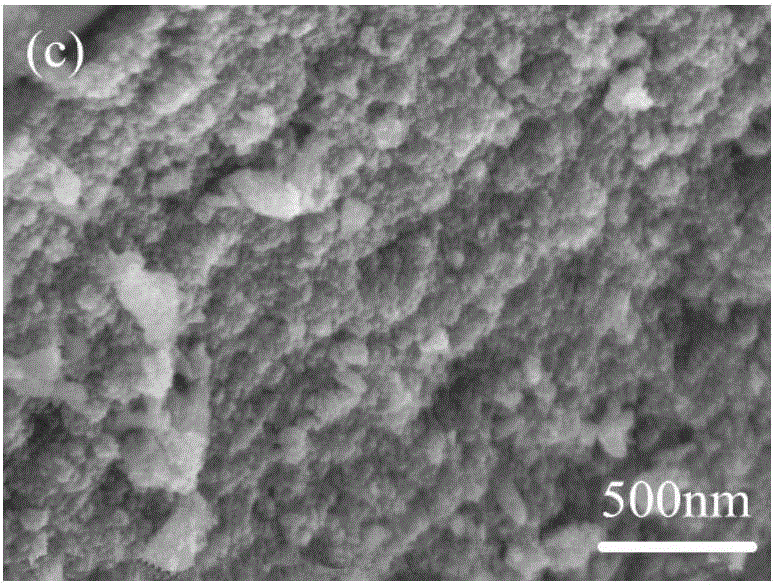

Image

Examples

Embodiment 1

[0028] The invention prepares Mo-TiO modified by low-temperature plasma 2 The method of photocatalytic material comprises the following steps:

[0029] (1) Add 10mL tetrabutyl titanate and 2mL triethanolamine to 50mL isopropanol to prepare a mixed solution, add 2g cetyl ammonium bromide (CTAB) and 3g glucose, stir at room temperature for 30min until the mixture is uniform , to obtain solution I;

[0030](2) Add 0.1g of ammonium molybdate and 1.5mL of deionized water into 25mL of isopropanol, adjust the pH value to 4-6 with 65%wt concentrated nitric acid, stir well to make it evenly mixed, and obtain solution II;

[0031] (3) Add solution II obtained in step (2) dropwise to solution I obtained in step (1) at a rate of 30-50 drops / min with a separatory funnel under vigorous stirring to make tetrabutyl titanate Slowly hydrolyze, continue to stir for 1 hour after the dropwise addition to obtain light yellow uniform and transparent TiO 2 Sol, then aged at room temperature for 24...

Embodiment 2

[0077] The invention prepares Mo-TiO modified by low-temperature plasma 2 The method of photocatalytic material comprises the following steps:

[0078](1) Add 10mL of isopropyl titanate and 5mL of acetylacetone to 100mL of absolute ethanol to prepare a mixed solution, add 1g of CTAB and 5g of glucose, and stir at room temperature for 30min until uniformly mixed to obtain solution I;

[0079] (2) Add 0.05g of ammonium molybdate and 2mL of deionized water into 50mL of isopropanol, adjust the pH value to 4-6 with 65%wt concentrated nitric acid, stir well to make it evenly mixed, and obtain solution II;

[0080] (3) Add solution II obtained in step (2) dropwise to solution I obtained in step (1) at a rate of 30-50 drops / min with a separating funnel under vigorous stirring to make isopropyl titanate Slowly hydrolyze, continue to stir for 1 hour after the dropwise addition to obtain light yellow uniform and transparent TiO 2 Sol, then aged at room temperature for 24h to make it ge...

Embodiment 3

[0085] The invention prepares Mo-TiO modified by low-temperature plasma 2 The method of photocatalytic material comprises the following steps:

[0086] (1) Add 10mL of titanium chloride and 3mL of acetylacetone to 60mL of absolute ethanol to prepare a mixed solution, add 2g of amphiphilic triblock copolymer and 3g of glucose, stir at room temperature for 30min until the mixture is uniform, and obtain solution Ⅰ ;

[0087] (2) Add 0.5g of ammonium molybdate and 1mL of deionized water into 30mL of isopropanol, adjust the pH value to 4-6 with 65%wt concentrated nitric acid, stir well to make it evenly mixed, and obtain solution II;

[0088] (3) Add solution II obtained in step (2) dropwise to solution I obtained in step (1) at a rate of 30-50 drops / min with a separatory funnel under vigorous stirring to slowly hydrolyze titanium chloride , continue to stir for 1h after the dropwise addition to obtain light yellow uniform and transparent TiO 2 Sol, then aged at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com