An acidic pipeline cleaning agent and a preparing method thereof

A pipeline cleaning agent and acidic technology, which is applied in the direction of surface-active detergent composition, detergent compounding agent, detergent composition, etc., can solve the problems of failure to take any measures to ensure the stability of the composition, threats to the health of organisms, pipeline aging, etc. problems, achieve the effect of facilitating the residue of cleaning agents, promoting rapid peeling and decomposition, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

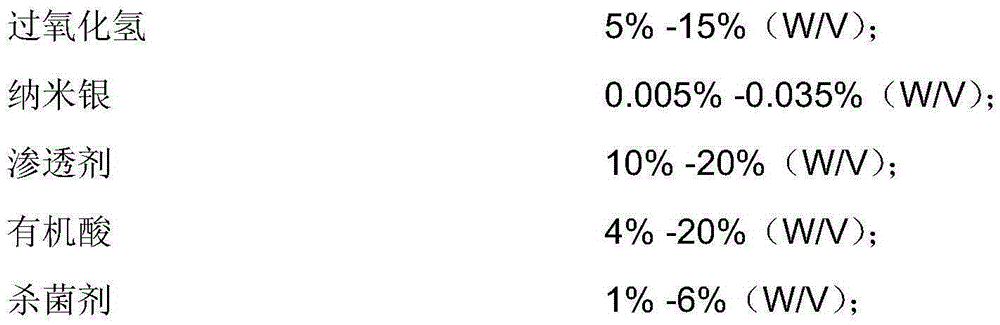

[0033] A kind of acid pipe cleaning agent, according to the mass of feeding, every 1000ml prepared, its raw material composition is as follows:

[0034]

[0035] Preparation:

[0036] (1), add 150g of deionized water in the liquid distribution tank;

[0037] (2) Add 100g of acetic acid, 86g of glycolic acid (70%), 30g of disodium ethylenediaminetetraacetate and 0.1g of acid lake blue into the liquid mixing tank, stir until completely dissolved; and stir, then add 100g fatty alcohol polyoxyethylene ether (AEO-9) and 167g dodecyldimethylamine oxide (30%), 25g dodecyldimethylbenzyl ammonium bromide (80%), stir until completely dissolved ;

[0038] (3), in the case of continuous stirring, first add 0.15g nano-silver, then add 160g hydrogen peroxide (50%), finally add deionized water to 1000ml, and fully stir until uniform;

[0039] (4), adding 30% phosphoric acid solution in an appropriate amount to adjust the pH value between 3.0-4.0, to obtain.

Embodiment 2

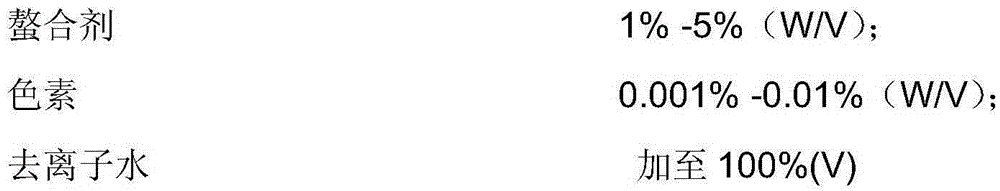

[0041] A kind of acid pipe cleaning agent, according to the mass of feeding, every 1000ml prepared, its raw material composition is as follows:

[0042]

[0043] Preparation:

[0044] (1), 160g acetic acid, 160g peracetic acid (25%), 8g hydroxyethylidene diphosphonic acid, 7g polyacrylic acid (30%) and 0.1g acid lake blue are added in the liquid mixing tank while stirring, Add 333g cocamidopropyl betaine (30%) afterwards, 86g didecyl dimethyl ammonium chloride (70%), stir until fully dissolving;

[0045] (2), in the case of continuous stirring, first add 0.25g nano-silver, then add 240g hydrogen peroxide (50%), finally add deionized water to 1000ml, and fully stir until uniform;

[0046] (3) Adding 30% phosphoric acid solution in an appropriate amount to adjust the pH value between 2.0-3.0, to obtain final product.

Embodiment 3

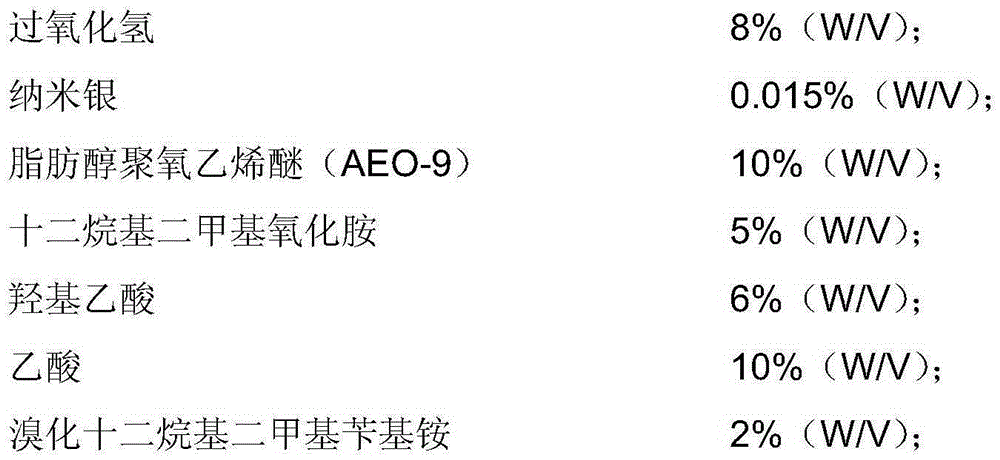

[0048] A kind of acid pipe cleaning agent, according to the mass of feeding, every 1000ml prepared, its raw material composition is as follows:

[0049]

[0050]

[0051] Preparation:

[0052] (1), add 100g of deionized water in the liquid distribution tank;

[0053] (2), 47g formic acid (85%), 10g benzoic acid (dissolved with 50ml absolute ethanol), 16g diethylenetriaminepentamethylenephosphonic acid (50%), 7g polyacrylic acid (30%) and 0.05g acid Lake blue, add to the liquid mixing tank while stirring, then add 150g fatty alcohol polyoxyethylene ether (AEO-7) and 125g 2-alkyl-N-carboxymethyl-N-hydroxyethyl imidazoline betaine (40%), 14g octadecyltrimethylammonium chloride (70%), stirred until fully dissolved;

[0054] (3), in the case of continuous stirring, first add 0.05g nano silver, then add 100g hydrogen peroxide (50%), finally add deionized water to 1000ml, and fully stir until uniform;

[0055] (4), adding 30% phosphoric acid solution in an appropriate amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com