Automatic rubber feeding machine

An automatic feeding and rubber technology, applied in the direction of conveyor objects, loading/unloading, cleaning devices, etc., can solve the problems of accumulated rubber sticky dirt, difficult to cut, rubber bottom adhesion, etc., to reduce slippage and facilitate post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

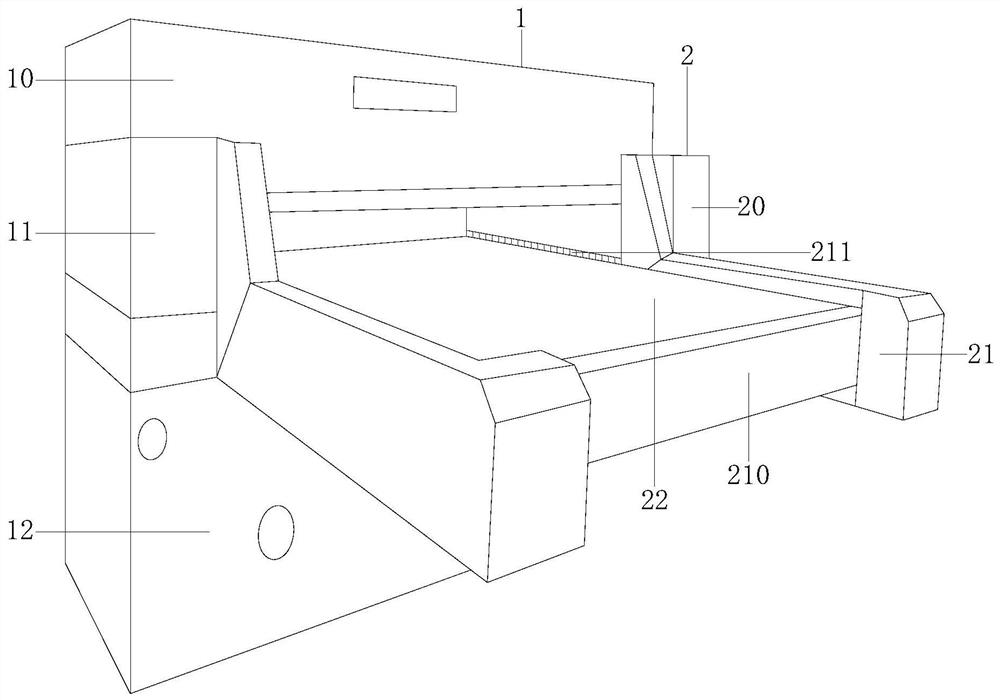

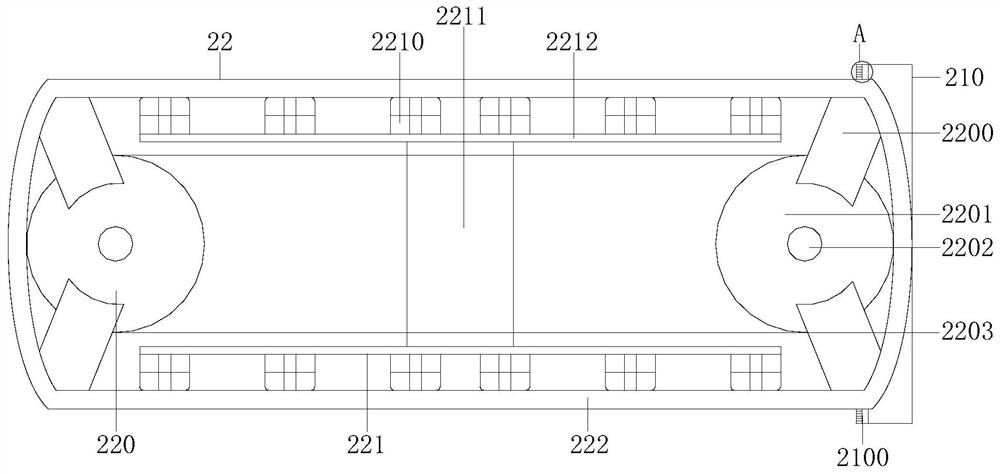

[0024] Example 1 see Figure 1-3 , the present invention provides a technical solution for a rubber automatic feeding machine: its structure includes a feeding frame 1 and a conveying frame 2, the feeding frame 1 is installed and connected to the rear end of the conveying frame 2, and the feeding machine The frame 1 is composed of an upper frame 10, a middle frame 11, and a bottom frame 12. The upper frame 10 is connected to the upper end of the middle frame 11, and the upper end of the middle frame 11 is locked with the bottom frame 12. The conveyor frame 2 includes a side frame 20 , conveying rack 21, conveying structure 22, described side mounting frame 20 is installed and connected with the rear end of conveying rack 21, the left and right ends of described conveying structure 22 are embedded in conveying rack 21, and the front end of described conveying rack 21 is installed There is a pre-conveying rack 210, and a side-mounted air conditioner 211 is installed at the rear ...

Embodiment 2

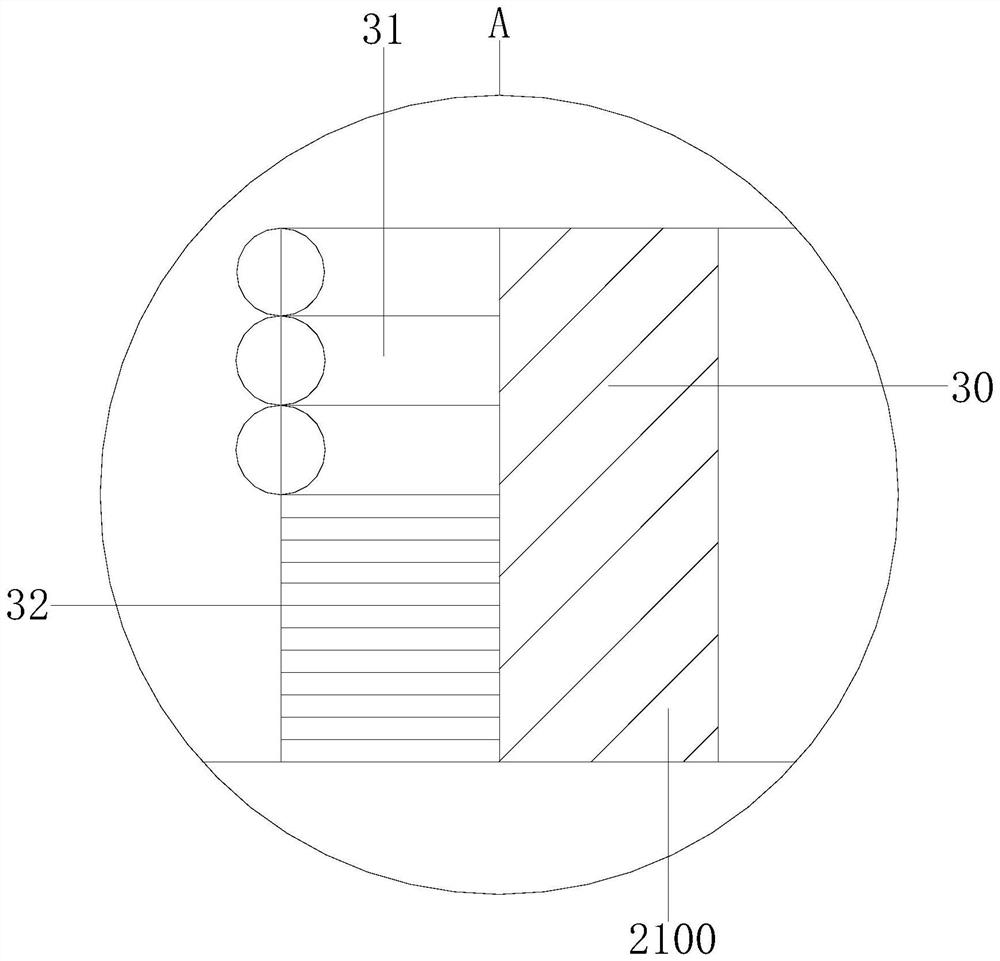

[0026] Example 2 see Figure 4-5 , the present invention provides a technical solution for an automatic rubber feeder: the convex structure 2210 includes a push rod 40, a main frame 41, and a horizontal bracket 42, and the main frame 41 is installed and connected to the push rod 40 and the horizontal bracket 42. The push rod 40 is connected to the middle track of the horizontal support 42. The left and right ends of the push rod 40 are arc-shaped structures, which minimize the wear and tear on the conveying structure 22 when pushing up. The conveying belt 222 includes a bottom belt 2220 , the middle belt 2221, the upper belt 2222, the upper and lower sides of the middle belt 2221 are glued to the bottom belt 2220 and the upper belt 2222, the middle part of the middle belt 2221 is provided with a grain bin 50, and the upper part of the upper belt 2222 is provided with a rubber The convex strip 51, the rubber convex strip 51 reduces the slipping of the rubber during transportati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com