Modified emulsified asphalt and preparation method thereof

A technology of emulsifying asphalt and modification, which is applied to building components, building insulation materials, buildings, etc., and can solve problems such as low solid content and high Engelder viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of the modified emulsified asphalt described in the above technical scheme, comprising the following steps:

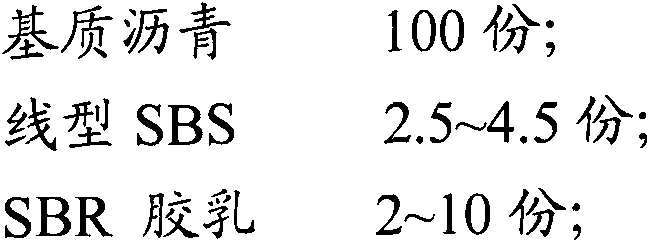

[0035] (1) Mix liquid matrix asphalt with linear SBS, compatibilizer and sulfur, and obtain SBS modified asphalt after shearing;

[0036] (2) mixing emulsifier and hydrochloric acid, saponification reaction takes place to obtain soap liquid;

[0037] (3) the SBS modified asphalt obtained in the step (1) is mixed with the soap liquid obtained in the step (2) and the naphthenic distillate oil to obtain a mixed material;

[0038] (4) the mixed material obtained in the step (3) is mixed with the SBR latex to obtain a modified emulsified asphalt;

[0039] The time sequence of the steps (1) and (2) is not limited.

[0040] In the present invention, the raw material of base asphalt is preferably heated to obtain liquid base asphalt. The heating temperature is preferably 130-150°C, more preferably 140-145°C, a...

Embodiment 1

[0057] Weigh 800g of No. 70 heavy-duty asphalt and heat it to 185°C, add 35g of linear SBS, 12g of compatibilizer and 2.3g of sulfur into the base asphalt at the same time, and use high-speed shearing machine to shear and disperse for 90min to make SBS modified asphalt .

[0058] Mix 6g of emulsifier with 710g of hydrochloric acid heated to 70°C, adjust the pH to 2, and make soap.

[0059] The SBS modified asphalt was kept at a constant temperature of 120°C, and 32 g of SBS modified asphalt, viscosity reducer and soap solution were added to the colloid mill at the same time, and SBS modified emulsified asphalt was obtained after high-speed shearing.

[0060] Add 30g of SBR latex into SBS modified emulsified asphalt and stir for 2 hours to obtain modified emulsified asphalt. The test data are shown in Table 1.

Embodiment 2

[0062] Weigh 800g of No. 70 heavy-duty asphalt and heat it to 185°C. Add 36g of linear SBS, 24g of compatibilizer and 2g of sulfur to the base asphalt at the same time, and use high-speed shearing machine to shear and disperse for 120min to make SBS modified asphalt.

[0063] Mix 6g of emulsifier with 710g of hydrochloric acid heated to 60°C, adjust the pH value to 2.5, and make soap liquid.

[0064] The SBS modified asphalt was kept at a constant temperature of 140°C, and 48 g of SBS modified asphalt, viscosity reducer and soap solution were added to the colloid mill at the same time, and SBS modified emulsified asphalt was obtained after high-speed shearing.

[0065] Add 12g of SBR latex into SBS modified emulsified asphalt and stir for 6 hours to obtain modified emulsified asphalt. The test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com