A surface amphiphilic nano-nickel sulfide catalyst and its preparation method and application

A surface amphiphile, nickel sulfide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, nanotechnology, etc., can solve the problems that did not mention the hydrophilic and hydrophobic properties of the surface of nickel sulfide, and did not mention the catalytic activity of hydrogenation, etc. Achieve good application prospects and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

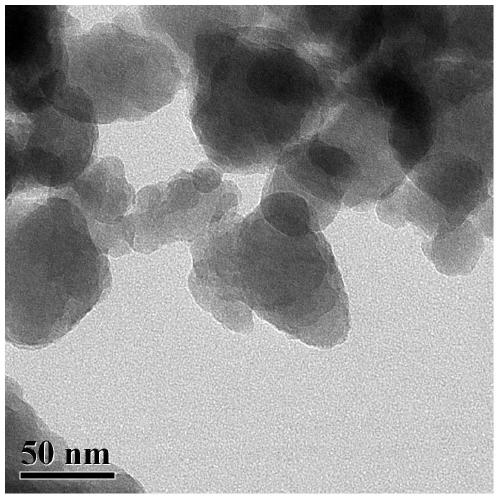

[0035] This example illustrates the method of using 1-ethyl-3-methylimidazolium tetrafluoroborate to prepare surface amphiphilic nano nickel sulfide hydrogenation catalyst.

[0036] Add a certain amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), make the concentration of nickel reach 0.01mol / L, stir until uniform; Add ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate in the above-mentioned mixture, make 1-ethyl-3-methyl Imidazole tetrafluoroborate: nickel nitrate (molar ratio) reaches 24:1, stir until uniform, add sodium sulfide aqueous solution to the above mixture, make sodium sulfide: nickel nitrate (molar ratio) reach 2.5:1, stir until uniform, React at 80°C for 12h to configure the initial reaction mixture; transfer the initial reaction mixture to a high-pressure synthesis kettle, and crystallize at 200°C for 4h. After the crystallization is completed, the reactant is cooled to room temperature, filtered, washed with deionized water and dried to obta...

Embodiment 2

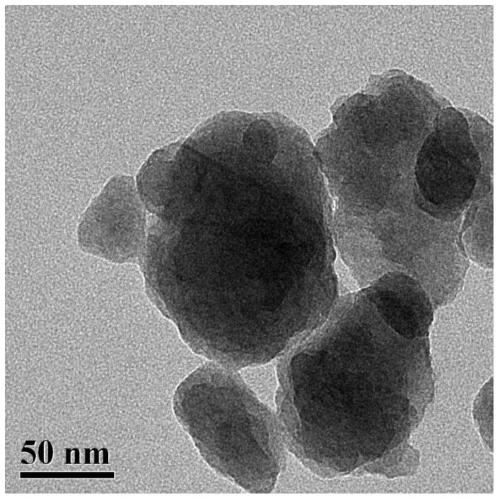

[0039] This example illustrates the method of using 1-butyl-3-methylimidazolium hexafluorophosphate to prepare a surface amphiphilic nano-nickel sulfide hydrogenation catalyst.

[0040] Add a certain amount of nickel stearate (Ni(H 3 C(CH 2 ) 16 CO 2 ) 2 ), make the concentration of nickel reach 0.015mol / L, stir until uniform; add ionic liquid 1-butyl-3-methylimidazole hexafluorophosphate in the above mixture, make 1-butyl-3-methylimidazole hexafluorophosphate Fluorophosphate: nickel stearate (molar ratio) reaches 18:1, stirs until uniform, adds potassium sulfide aqueous solution to above-mentioned mixture, makes potassium sulfide: potassium nickelate (molar ratio) reaches 4:1, stirs until uniform, React at 40°C for 24h to configure the initial reaction mixture; transfer the initial reaction mixture to a high-pressure synthesis kettle, and crystallize at 180°C for 10h. After the crystallization is completed, the reactant is cooled to room temperature, filtered, washed wit...

Embodiment 3

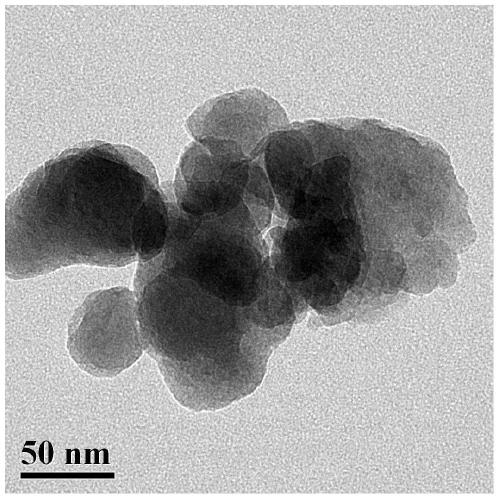

[0042] This example illustrates the method of using 1-propyl-3-methylimidazolium bromide to prepare surface amphiphilic nano nickel sulfide hydrogenation catalyst.

[0043] Add a certain amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 (0), make the concentration of nickel reach 0.5mol / L, stir until uniform; Add ionic liquid 1-propyl-3-methylimidazolium bromide in the above-mentioned mixture, make 1-propyl-3-methylimidazolium bromide : nickel nitrate (molar ratio) reaches 0.01:1, stir until uniform; add hydrogen sulfide aqueous solution to the above mixture, make hydrogen sulfide: nickel nitrate (molar ratio) reach 2:1, stir until uniform, react at 50 ℃ for 20h, Configure the initial reaction mixture; transfer the initial reaction mixture to a high-pressure synthesis kettle, and crystallize at 160° C. for 40 h. After the crystallization is completed, the reactant is cooled to room temperature, filtered, washed with deionized water and dried to obtain a surface amphip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com