A surface amphiphilic nano-tungsten-molybdenum sulfide hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst, tungsten and molybdenum sulfide technology, used in physical/chemical process catalysts, nanotechnology for materials and surface science, chemical instruments and methods, etc. Complex composition, etc., to achieve good application prospects, good surface amphiphilicity, and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

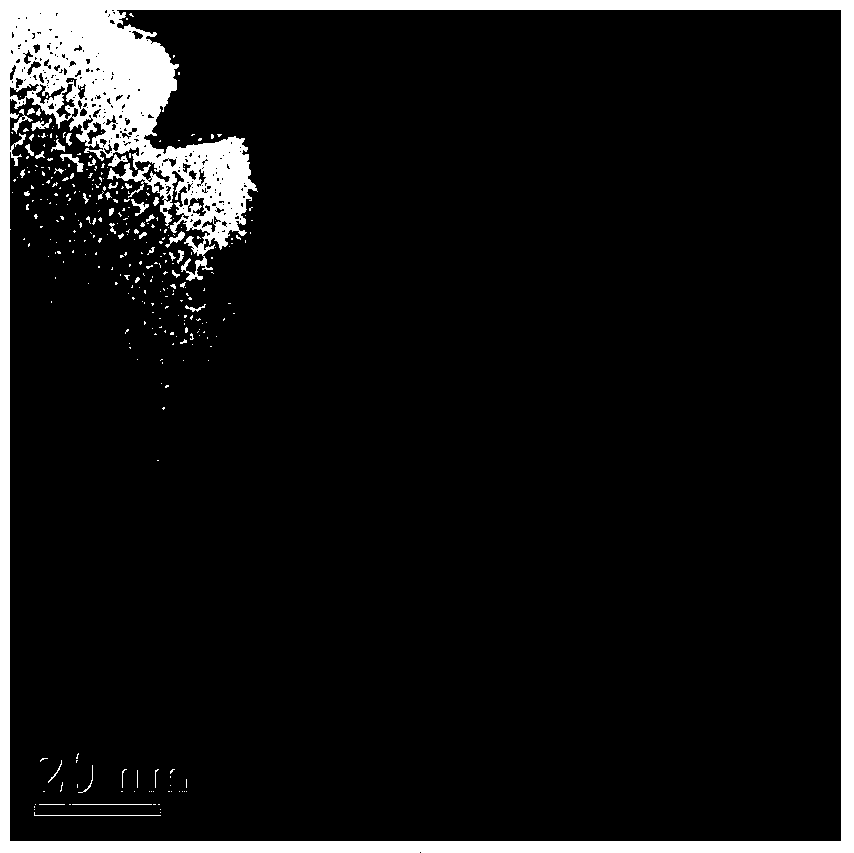

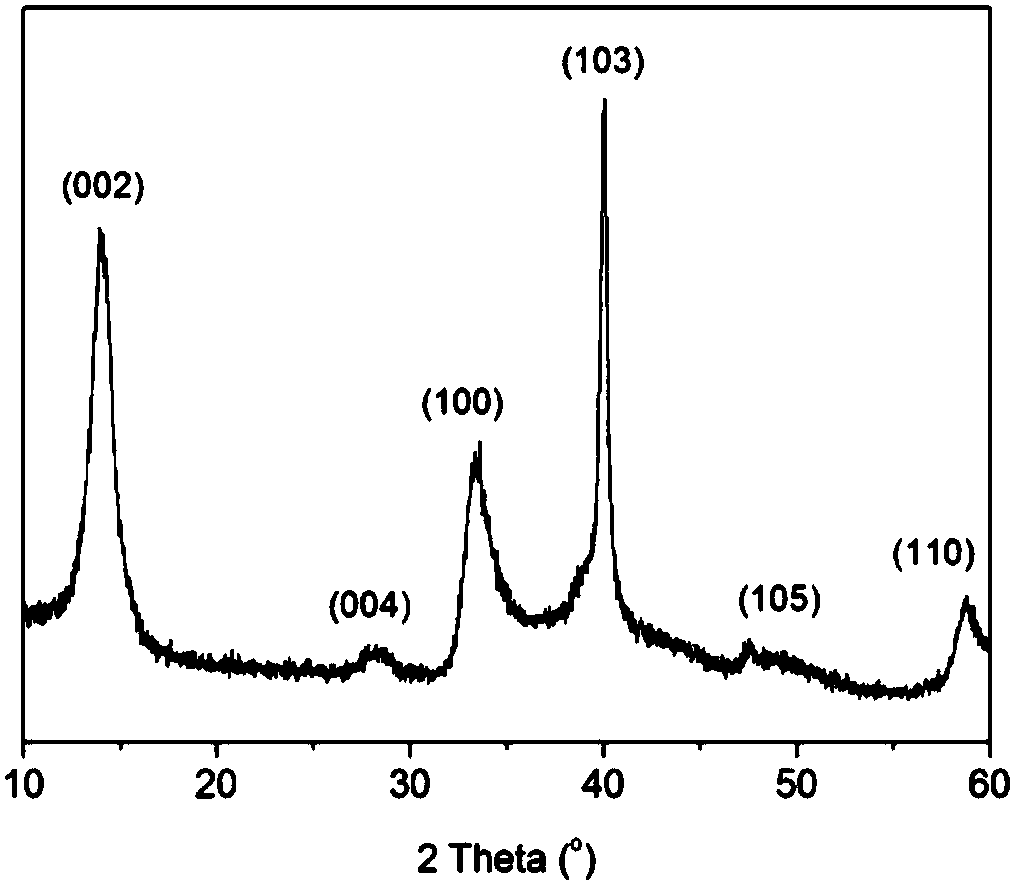

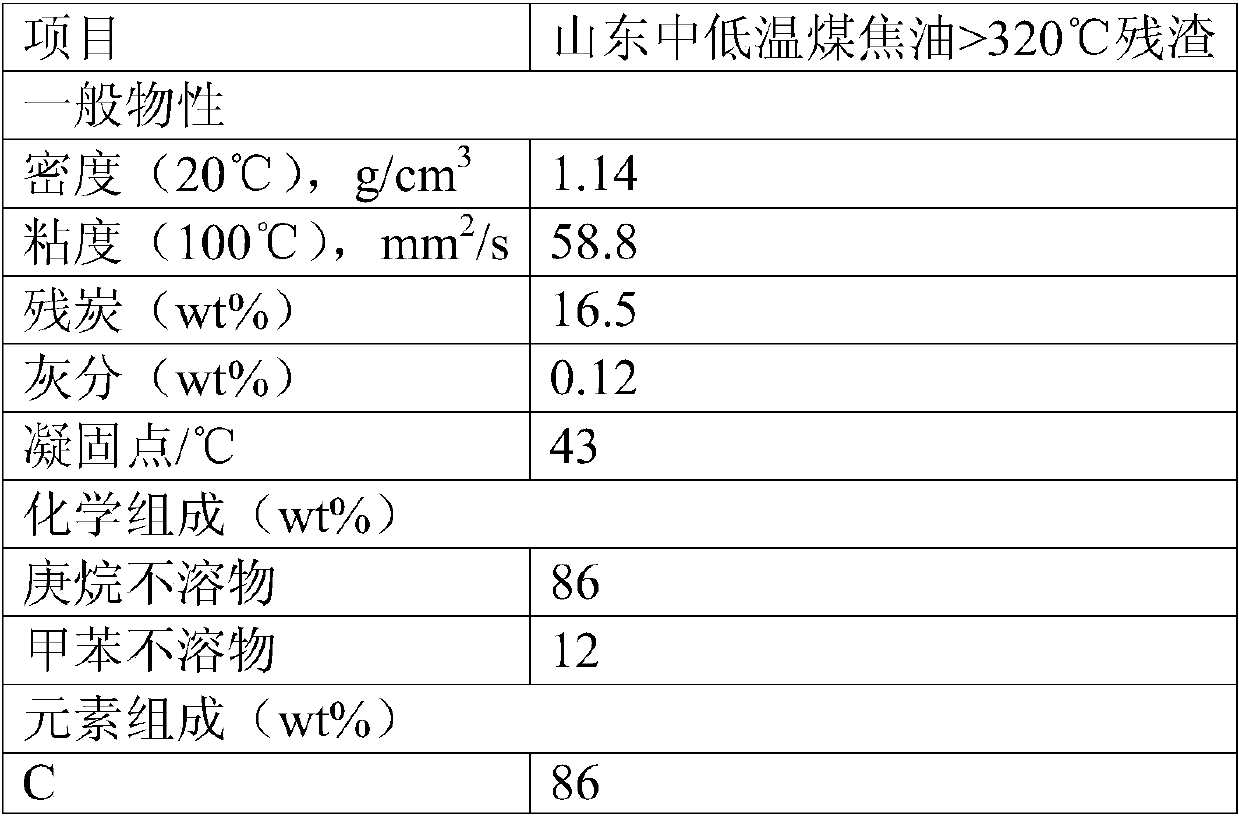

[0033] This example illustrates the method of using 1-butyl-3-methylimidazolium tetrafluoroborate to prepare surface amphiphilic nano-tungsten-molybdenum sulfide hydrogenation catalyst.

[0034] Add a certain amount of sodium tungstate to 500mL deionized water to make the concentration of tungsten reach 0.01mol / L, and stir until uniform; add a certain amount of molybdenum acid to make the concentration of molybdenum reach 0.1mol / L Add sodium sulfide to the above mixture aqueous solution, so that Na 2 S: (W+Mo) (molar ratio) reaches 2.5:1, stir until uniform, and react at 75°C for 15 hours; add hydroxylamine hydrochloride to the above mixture to make hydroxylamine hydrochloride: (W+Mo) (molar ratio) reach 4: 1. Stir until uniform; add ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate to the above mixture to make 1-butyl-3-methylimidazolium tetrafluoroborate: (W+Mo ) (molar ratio) reached 24:1, stirred until uniform, and configured as an initial reaction mixture; the i...

Embodiment 2

[0036] This example illustrates the method of using 1-propyl-3-methylimidazolium hexafluorophosphate to prepare surface amphiphilic nanometer tungsten-molybdenum sulfide hydrogenation catalyst.

[0037] Add a certain amount of potassium tungstate to 500mL deionized water to make the concentration of tungsten reach 0.015mol / L, and stir until uniform; add a certain amount of ammonium molybdate to make the concentration of molybdenum reach 0.001mol / L; stir until uniform to the above Aqueous potassium sulfide solution was added to the mixture to make K 2 S: (W+Mo) (molar ratio) reaches 5:1, stir until uniform, and react at 60°C for 18 hours; add potassium borohydride to the above mixture to make potassium borohydride: (W+Mo) (molar ratio) reach 2.8:1, stir until uniform; add ionic liquid 1-propyl-3-methylimidazolium hexafluorophosphate to the above mixture to make 1-propyl-3-methylimidazolium hexafluorophosphate: (W+Mo ) (molar ratio) reached 16:1, stirred until uniform, and conf...

Embodiment 3

[0039] This example illustrates the method of using 1-pentyl-3-methylimidazolium bromide to prepare surface amphiphilic nano-tungsten-molybdenum sulfide hydrogenation catalyst.

[0040] Add a certain amount of tungsten nitrate to 500mL deionized water to make the concentration of tungsten reach 0.5mol / L, and stir until uniform; add a certain amount of sodium molybdate to make the concentration of molybdenum reach 1.5mol / L, and stir until uniform; Add hydrogen sulfide aqueous solution to the mixture to make hydrogen sulfide: (W+Mo) (molar ratio) reach 2.2:1, stir until uniform, and react at 55°C for 17h; add polyethyleneimine to the above mixture to make polyethyleneimine : (W+Mo) (molar ratio) reaches 1.9:1, stir until uniform; add ionic liquid 1-pentyl-3-methylimidazolium bromide to the above mixture, make 1-pentyl-3-methylimidazolium bromide Bromine salt: (W+Mo) (molar ratio) reaches 0.02:1, stir until uniform, and configure the initial reaction mixture; transfer the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com