Modified silicon dioxide microspheres for absorbing heavy metal lead ion

A technology of silica and lead ions, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, adsorption water/sewage treatment, etc., can solve problems such as lead pollution, reduce the content of heavy metal lead, and settle and separate Good performance, excellent dispersion and emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

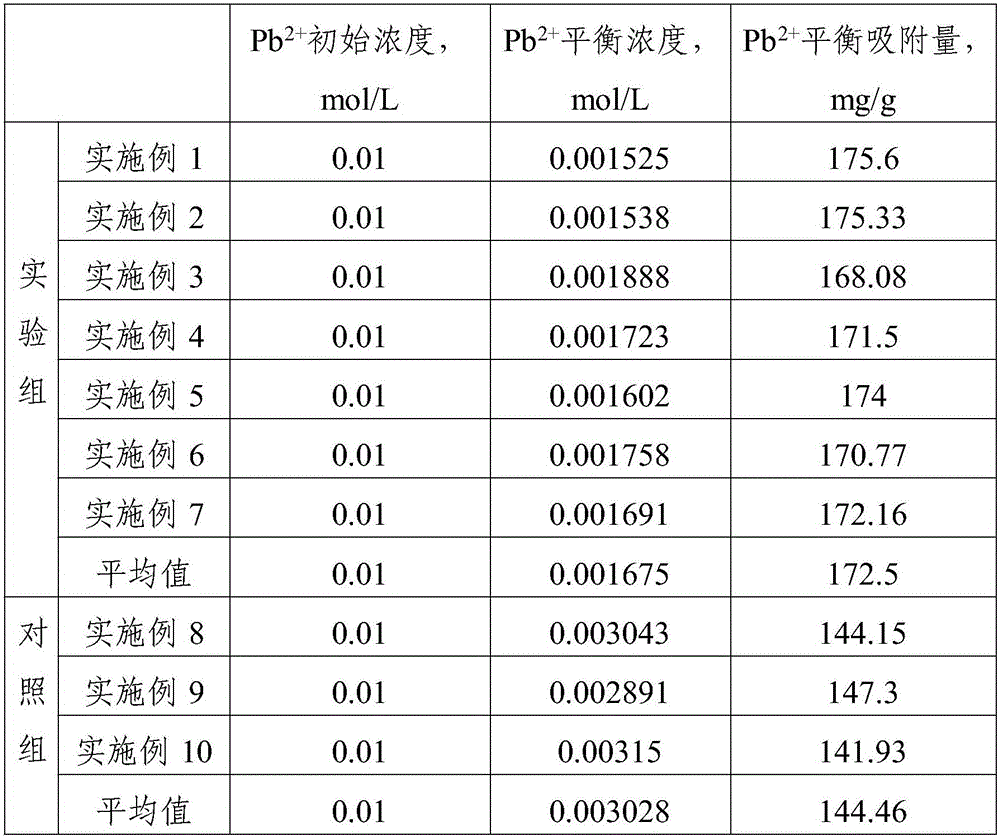

Examples

Embodiment 1

[0017] A modified silica microsphere for the adsorption of heavy metal lead ions is composed of the following parts by mass: 8 parts of water glass, 13.5 parts of ethyl orthosilicate, 4 parts of disodium calcium edetate, 4.3 parts of triethanolamine, 4 parts of ammonia water, 6 parts of humic acid, 4.8 parts of magnetic nucleating agent, 6 parts of organic bentonite, 18 parts of ethanol, 4 parts of aminopropyltrimethoxysilane, 4 parts of mordenite, and 4 parts of fatty alcohol polyoxyethylene ether.

[0018] A method for preparing modified silica microspheres for heavy metal lead ion adsorption, the preparation steps are as follows:

[0019] 1) Weighing raw materials by weight, pulverizing and blending humic acid, machine bentonite and mordenite to obtain mixture 1;

[0020] 2) Mix fatty alcohol polyoxyethylene ether and ethanol, ultrasonically disperse for 10 minutes, add magnetic nucleating agent, water glass and ethyl orthosilicate, heat to 58°C, stir at 65r / min for 15 minu...

Embodiment 2

[0024] A modified silica microsphere for the adsorption of heavy metal lead ions is composed of the following parts by mass: 9 parts of water glass, 14 parts of ethyl orthosilicate, 3 parts of calcium disodium edetate, 5.8 parts of triethanolamine, 8 parts of ammonia water, 8 parts of humic acid, 5 parts of magnetic nucleating agent, 7 parts of organic bentonite, 15 parts of ethanol, 6 parts of aminopropyltrimethoxysilane, 3 parts of mordenite, and 6 parts of fatty alcohol polyoxyethylene ether.

[0025] A method for preparing modified silica microspheres for heavy metal lead ion adsorption, the preparation steps are as follows:

[0026] 1) Weighing raw materials by weight, pulverizing and blending humic acid, machine bentonite and mordenite to obtain mixture 1;

[0027] 2) Mix fatty alcohol polyoxyethylene ether and ethanol, ultrasonically disperse for 11 minutes, add magnetic nucleating agent, water glass and ethyl orthosilicate, heat to 58°C, stir at 70r / min for 15 minutes,...

Embodiment 3

[0031] A modified silica microsphere for heavy metal lead ion adsorption is composed of the following parts by mass: 8.5 parts of water glass, 15 parts of ethyl orthosilicate, 5 parts of calcium disodium edetate, 5 parts of triethanolamine, 6 parts of ammonia water, 7 parts of humic acid, 7 parts of magnetic nucleating agent, 10 parts of organic bentonite, 20 parts of ethanol, 7 parts of aminopropyltrimethoxysilane, 5 parts of mordenite, and 7 parts of fatty alcohol polyoxyethylene ether.

[0032] A method for preparing modified silica microspheres for heavy metal lead ion adsorption, the preparation steps are as follows:

[0033] 1) Weighing raw materials by weight, pulverizing and blending humic acid, machine bentonite and mordenite to obtain mixture 1;

[0034] 2) Mix fatty alcohol polyoxyethylene ether and ethanol, ultrasonically disperse for 12 minutes, add magnetic nucleating agent, water glass and ethyl orthosilicate, heat to 55°C, stir at 75r / min for 15 minutes, cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com