Lubricant composition

一种润滑油组合物、润滑油基础油的技术,应用在润滑组合物、石油工业、基料等方向,能够解决剪切稳定性降低等问题,达到优异低温粘度特性、优异剪切稳定性和高温度粘度特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0259] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited by these examples.

[0260] [Evaluation method]

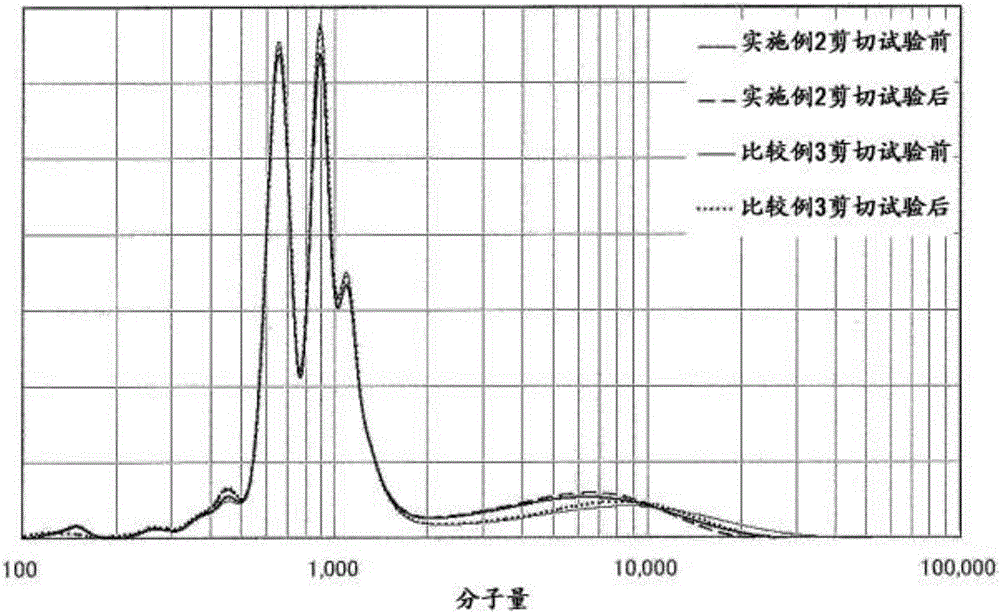

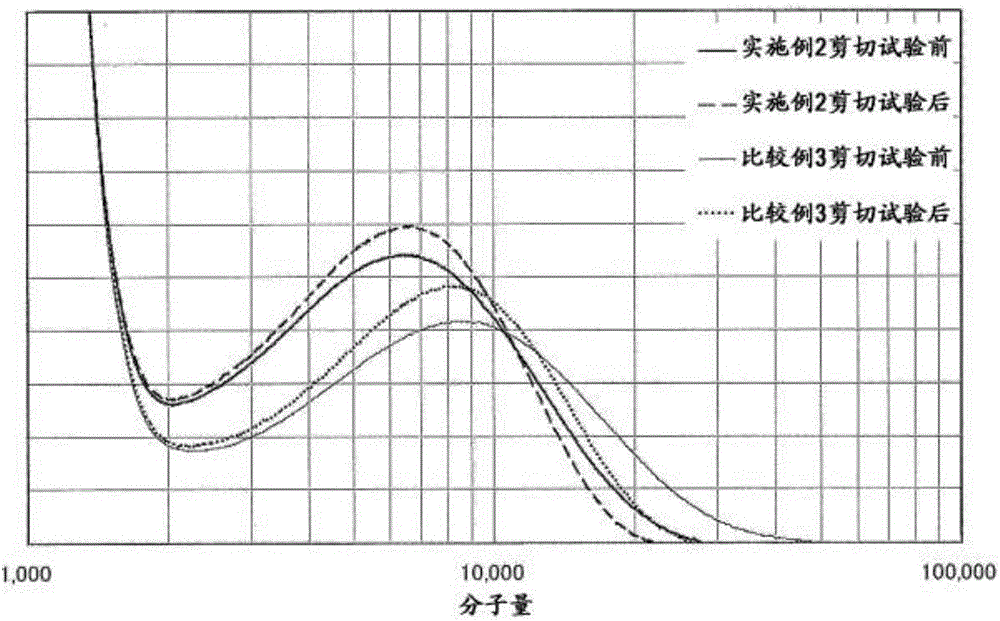

[0261] In the following examples and comparative examples, etc., the physical properties and the like of the ethylene-α-olefin copolymer and the lubricating oil composition were measured by the following methods.

[0262]

[0263] Using a Fourier transform infrared spectrophotometer FT / IR-610 or FT / IR-6100 manufactured by JASCO Corporation, calculate the 721cm value based on the rocking vibration of long-chain methylene -1 Absorption near 1155cm with propylene-based backbone vibration -1 The absorbance ratio of the nearby absorbance (D1155cm -1 / D721cm -1 ), and the ethylene content (weight %) was calculated using a calibration curve (prepared using standard samples in ASTM D3900) prepared in advance. Next, using the obtained ethylene content (weight%), the ethylene content (mol%) was c...

Synthetic example 1

[0293] [Methylphenylmethylene (η 5 - cyclopentadienyl) (η 5 Synthesis of -2,7-di-tert-butylfluorenyl)]zirconium dichloride

[0294] (i) Synthesis of 6-methyl-6-phenylfulvene (fulvene)

[0295] Under a nitrogen atmosphere, 7.3 g (101.6 mmol) of lithium cyclopentadiene and 100 mL of anhydrous tetrahydrofuran were added to a 200 mL three-necked flask and stirred. The solution was cooled in an ice bath, and 15.0 g (111.8 mmol) of acetophenone was added dropwise. After stirring at room temperature for 20 hours, the resulting solution was quenched with dilute aqueous hydrochloric acid. 100 mL of hexane was added to extract the soluble components, and the organic layer was washed with water and saturated brine, and dried over anhydrous magnesium sulfate. Then, the solvent was distilled off, and the obtained viscous liquid was separated by column chromatography (hexane) to obtain the target product (red viscous liquid).

[0296] (ii) Synthesis of methyl(cyclopentadienyl)(2,7-di-...

Embodiment 1

[0340] 28.0% by mass of the copolymer obtained in Polymerization Example 1 as the ethylene-α-olefin copolymer (B), 15.0% by mass of DIDA as the lubricating base oil (A), and the extreme pressure additive package (EP) It blended so that it might become 6.5 mass %, and further added PAO-6 as a lubricating oil base oil (A) to this so that the whole lubricating oil composition might become 100 mass %, and the lubricating oil composition was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat of fusion | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com