Semiconductor laser unit with pectinate current distribution and manufacturing method thereof

A current distribution and semiconductor technology, which is applied in the field of semiconductor lasers with comb-shaped current distribution and its production, can solve the problems of device performance impact, difficult production process, etc., meet the requirements of lower production process, strong anti-external feedback ability, high Effect of side mode suppression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

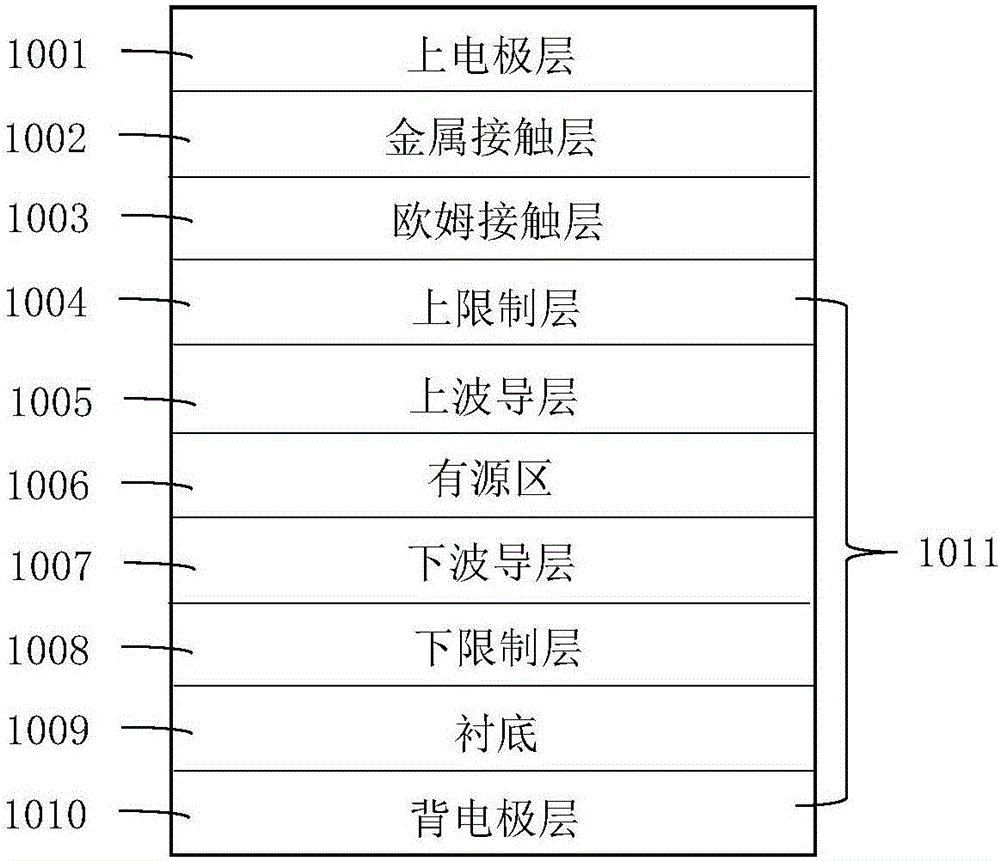

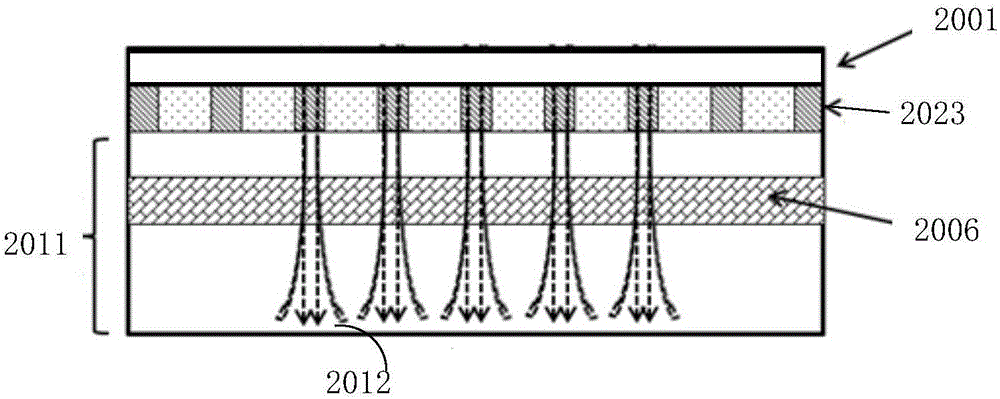

[0047] Such as figure 1 and image 3 As shown, the structure of the semiconductor laser is specifically: on the InP substrate 1009, there are successively a 1 μm InP lower confinement layer 1008, a 100nm InGaAsP lower waveguide layer 1007, a multi-quantum well active region 1006, a 100nm InGaAsP upper waveguide layer 1005, and a 300nm InP upper confinement layer. layer 1004, 200nm InGaAs ohmic contact layer 1003, Ti-Pt-Au metal contact layer 1002, upper electrode layer 1001, and the back electrode layer 1010 under the substrate 1009.

[0048] Among them, the multi-quantum well active region 1006 uses InGaAsP as the quantum well, AlGaInAs or InGaAsP as the potential barrier, the number of quantum well layers is 3-10 layers, the thickness of the quantum well layer is 5-8nm, and the thickness of the barrier layer is 5-10nm. It is 1.2%, and the central lasing wavelength is in the range of 1.2um-1.7um (specific parameters vary according to different designs).

[0049] The metal c...

Embodiment 2

[0060] This example Figure 4 As shown, the difference between it and Embodiment 1 is that the resistance of the metal contact layer 3002 in Embodiment 1 is a comb-shaped distribution structure, and the ohmic contact layer 4003 on the general structure 4011 in this embodiment includes a high resistance region 4027 and a low resistance In the region 4026, the resistance is distributed regularly in a comb shape, and the metal contact layer 4002 has a uniform distribution of resistance. Alternatively, the high resistance region 4027 may also be an oxide insulating region.

[0061] The manufacturing process of the semiconductor laser in this embodiment is,

[0062] 1) The MOCVD growth epitaxial structure includes: a lower confinement layer, a lower waveguide layer, an active region, an upper waveguide layer, an upper confinement layer, and an ohmic contact layer 4003;

[0063] 2) After electron beam exposure (or holographic lithography), diffusion or ion beam bombardment prepare...

Embodiment 3

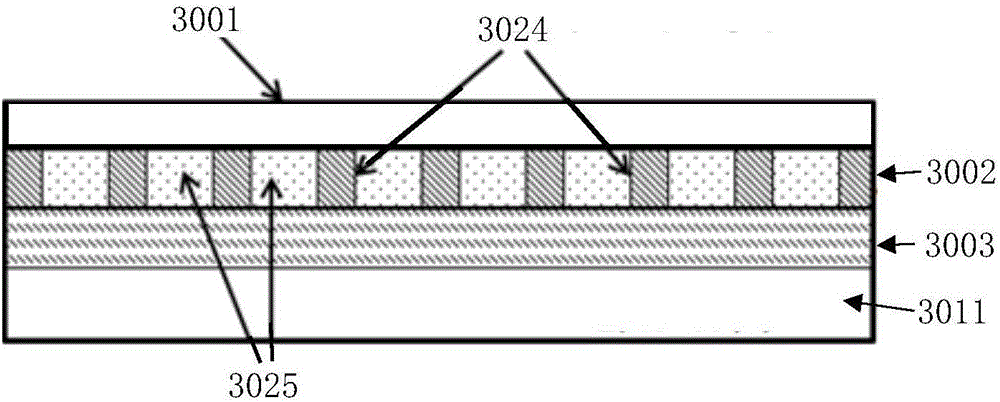

[0071] This example Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the comb structure in Embodiment 1 covers the entire metal contact layer 3002, and a part of the metal contact layer 5002 in this embodiment is a comb-shaped metal contact region 5024 and a comb-shaped The comb-like metal contact region 5023 formed by the oxidation insulating region 5025 is a uniform metal contact region 5029 . The comb-shaped metal contact region 5023 is located at one end of the uniform metal contact region 5029 (such as Figure 5 shown), or the comb-shaped metal contact region 5023 is located at both ends of the uniform metal contact region 5029 (not shown). Reference numeral 5011 denotes a general structure.

[0072] The manufacturing process of the semiconductor laser in this embodiment is:

[0073] 1) An epitaxial structure grown by MOCVD, the epitaxial structure comprising: a lower confinement layer, a lower waveguide layer, an active region, an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com