A surface gain lath medium with a high packing ratio and a manufacturing method thereof

A technology of filling ratio and surface layer, applied in active dielectric materials, laser components, electrical components, etc., can solve problems such as poor beam quality, achieve strong heat dissipation, high beam quality, and avoid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] When the host material is a laser crystal, according to the method embodiment of the present invention, a method for preparing a surface layer gain slab medium with a high filling ratio is provided, Figure 4 It is a flowchart of a method for preparing a slatted medium with a high filling ratio surface layer gain according to a method embodiment of the present invention, such as Figure 4 As shown, according to the method embodiment of the present invention, the preparation method of the lath medium with high filling ratio surface layer gain includes the following treatments:

[0040] Step 401, cutting and polishing the doped single crystal plate to obtain an upper doped layer and a lower doped layer respectively, wherein the doped single crystal plate is a laser crystal doped with active ions;

[0041] Step 402, selecting a first non-doped single crystal plate, and bonding the horizontal plane of the upper doped layer to the horizontal plane of the first non-doped sing...

example 1

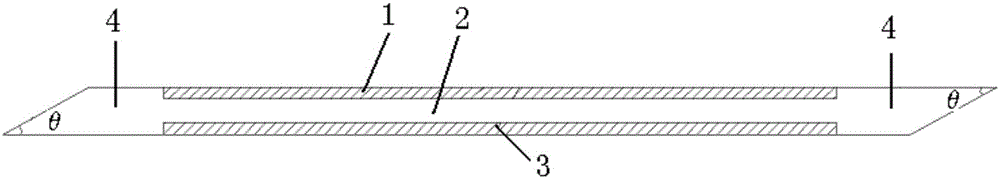

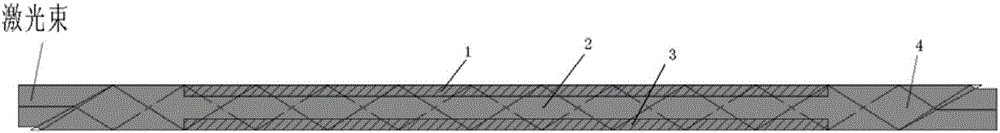

[0054] Taking Nd:YAG material as an example, the steps to realize the high filling ratio surface layer gain slab medium are as follows: using the method of single crystal diffusion bonding, first doping a finely polished Nd with a size of 96mm×26mm×1.2mm with 0.8at % Nd:YAG single crystal plate and a finely polished undoped YAG single crystal plate with a size of 96mm×26mm×3.5mm are bonded on a large surface of 96mm×26mm to obtain a YAG-Nd:YAG structure doped with Nd:YAG For the single crystal plate 1, the non-doped YAG single crystal part of the Nd:YAG single crystal plate 1 is thinned to 3 mm, and finely polished. Then another finely polished Nd-doped 0.8at% Nd:YAG single crystal plate with a size of 96mm×26mm×1.2mm and the non-doped YAG single crystal surface of Nd:YAG single crystal plate 1 were 96mm×26mm The large surface is bonded to obtain the Nd:YAG single crystal plate 2 of the Nd:YAG-YAG-Nd:YAG structure. The two ends of the Nd:YAG single crystal plate 2 are finely ...

example 2

[0056] The steps of adopting the ceramic sintering process to realize the high filling ratio surface layer gain slab medium are: first, prepare two YAG ceramic blanks with a size of 22mm×26mm×5.4mm, and one YAG ceramic blank with a size of 96mm×26mm×3mm, 96mm×26mm×1.2 mm of Nd doped with 1.2at% Nd: two pieces of YAG ceramic blanks, five blanks according to figure 1 Arrange and combine in the order shown and press them together directly, then sinter the blank according to the laser ceramic sintering process, after forming, cut the YAG—Nd:YAG—YAG ceramic part on both sides to 0.8mm, finely polish, and cut the end into cloth Ruster angle and required slat length, finely polished. The final Nd:YAG ceramic size is 136mm x 26mm x 4.6mm.

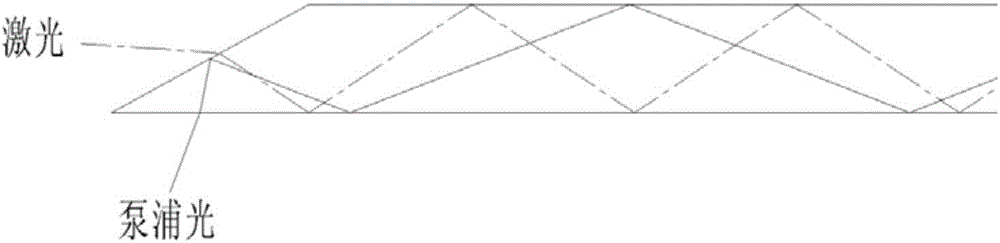

[0057] The innovatively designed high filling ratio surface gain slab medium of the present invention aims at the structural characteristics of the surface gain slab medium, and by rationally designing the doping area and cutting angle of the slab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com