A Composite Structured Laser Amplifier

A technology of laser amplifier and composite structure, applied in lasers, laser parts, laser parts and other directions, can solve the problem that lateral parasitic oscillation and pumping uniformity cannot be bypassed, high-quality laser output cannot be obtained, and the performance of laser ceramics needs to be improved and other problems, to achieve the effect of suppressing the coupling between transverse modes, small thermal distortion, and easy and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

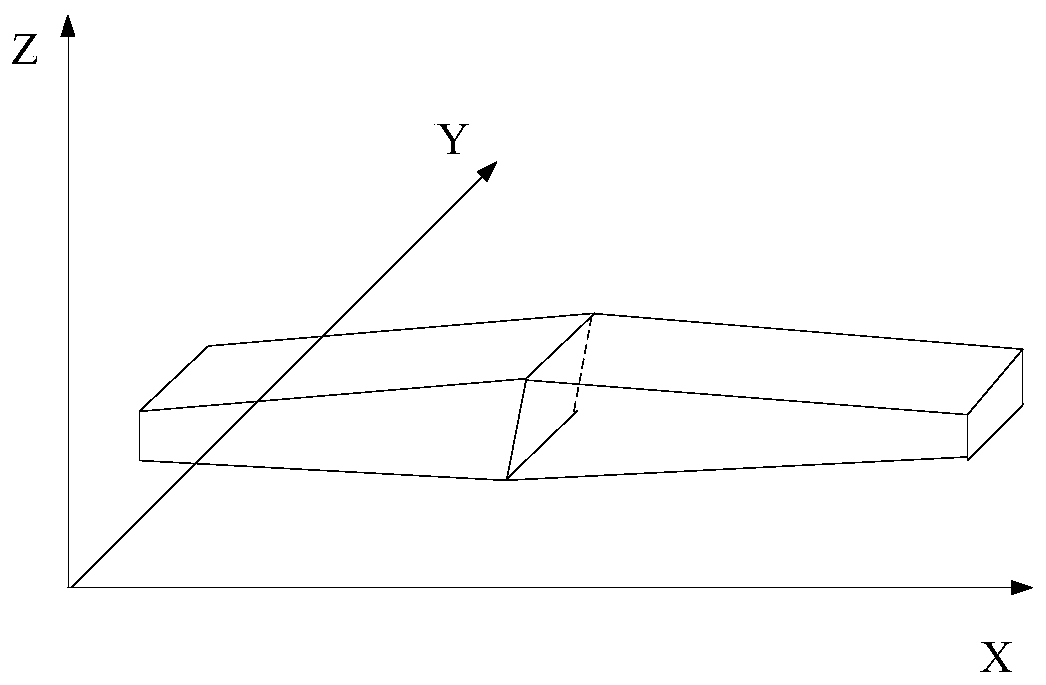

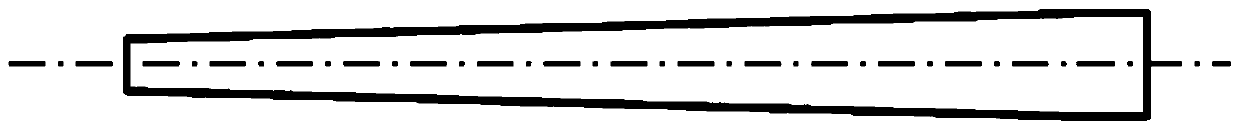

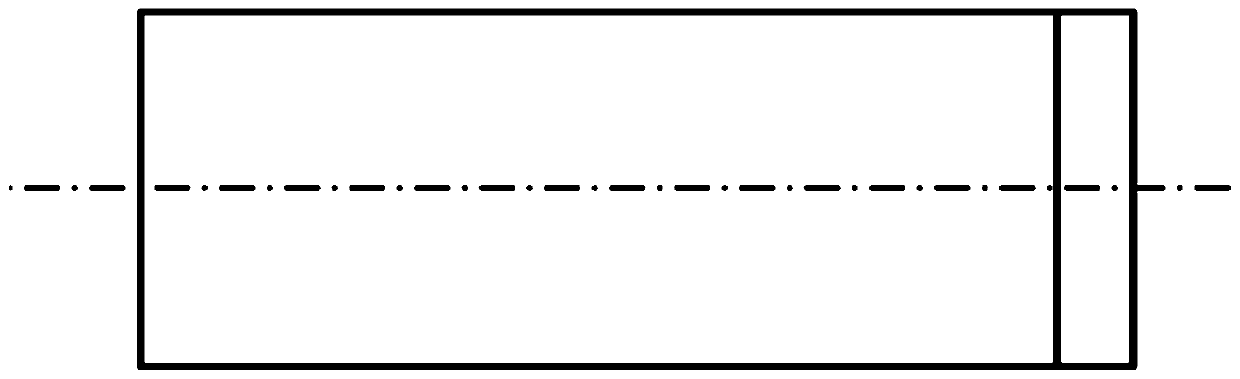

[0051] The composite structure laser amplifier of this embodiment includes a wedge-shaped laser sheet 1, a pump laser 5, a laser sheet fixture 2, a wedge-shaped laser sheet coupler 3, a coupler fixture 4, a pump source heat sink 6 and a mounting plate 7; Laser wafer 1 is a Nd:YAG crystal with a doping concentration of 1%, with a wedge angle of 2.86°, a length of 21mm, a height (2mm or 3mm), and a width of 10mm. The side view is shown in Figure 2(a), and the top view is shown in Figure 2 As shown in (b); the wedge-shaped laser sheet 1 is installed in the laser sheet fixture 2, and together with the wedge-shaped laser sheet coupler 3 and the pump laser 5 fixed in the coupler fixture 4 form a laser amplifier; figure 1 It is a schematic diagram of the wedge-shaped laser sheet unit of the composite structure of the present invention. The pump light is incident from the positive direction of X and transmitted along the Z direction. The thickness of the wedge-shaped laser sheet increa...

specific Embodiment 2

[0055] Taking a composite structure-based laser amplifier of the present invention as a basic array element of the laser weapon amplification system, this embodiment adopts a weapon-level array-type high-strength laser amplifier with 4 basic array elements, wherein the wedge-shaped laser slices 1, Four pump lasers 5, laser wafer fixtures 2, wedge-shaped laser sheet couplers 3, coupler fixtures 4, and pump source heat sinks 6 are selected respectively, and the four pump lasers 5 are placed side by side or arranged in pairs on the wedge-shaped laser. The two sides of the structure composed of the sheet 1 and the wedge-shaped laser sheet coupler 3 are independent and isolated from each other, and the installation method is the same as that of the first embodiment, such as image 3 As shown in the figure, the wedge-shaped sheet laser sheet of this embodiment is extended and spliced in the y direction, which is beneficial to suppress the coupling between transverse modes according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com