Ball grid array chip clamping holder for circuit board and development board

A circuit board and ball grid technology, applied in the field of ball grid matrix chip holders and development boards, can solve the problems of easily damaged components and soldering tin affecting the secondary welding effect, etc., to achieve convenient operation, meet chip installation requirements, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

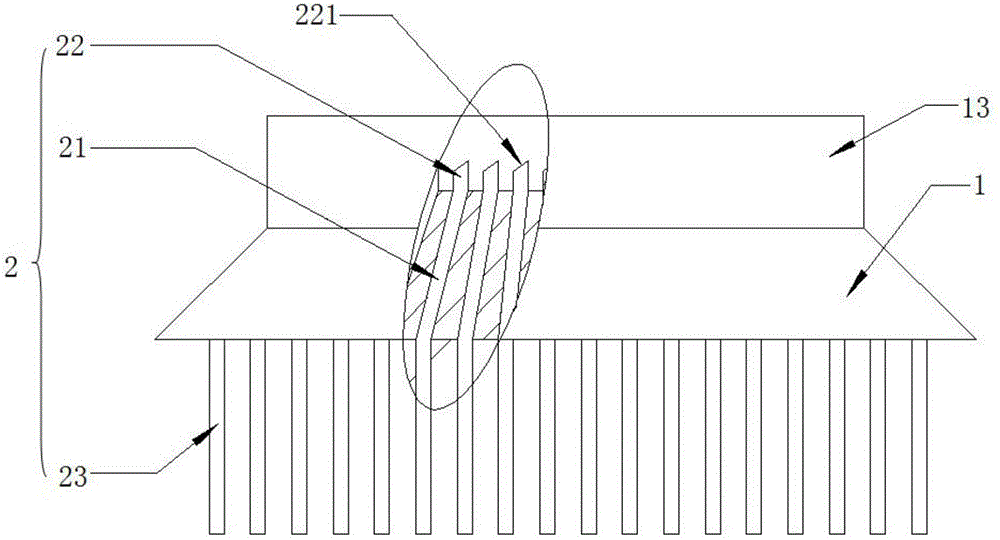

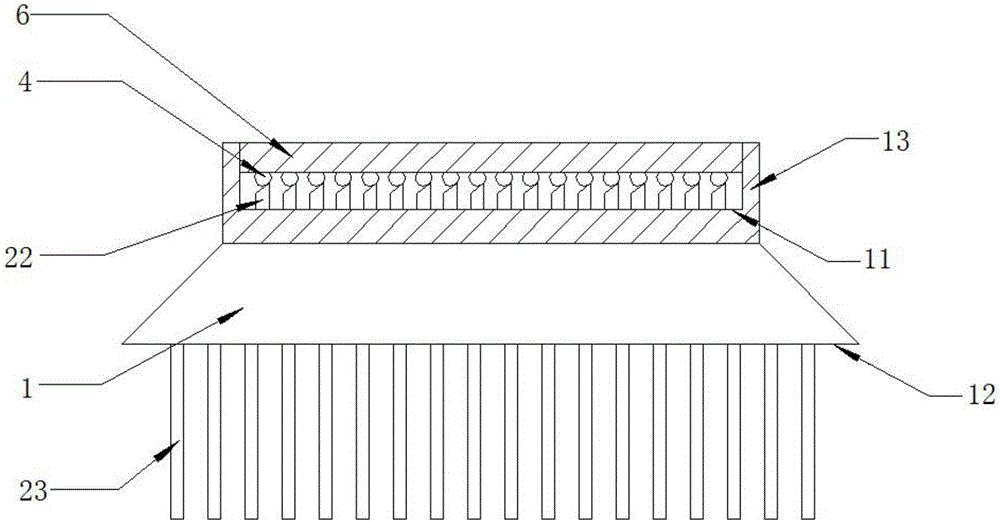

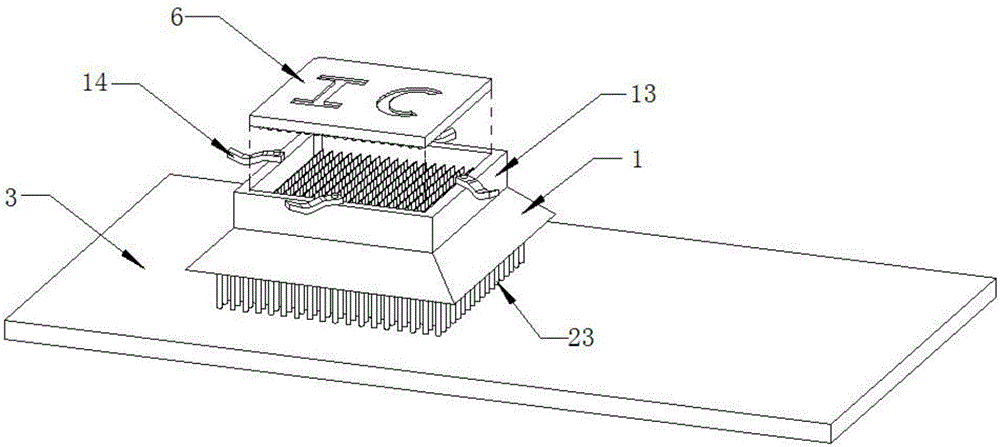

[0032] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, features and functions of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. In the following description, particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

[0033] Usually, the ball grid matrix chip 6 has a large number of pin solder balls 4 and the distance between the pin solder balls 4 is very small, and the ball grid matrix chip 6 is soldered and installed on the circuit board 3, especially the printed circuit board 3 (PCB board), it is usually necessary to use a multi-layer structure PCB board to meet the wiring requirements, and the soldering success rate between the solder balls 4 of each pin and the PCB board is diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com