A kind of bacterial cellulose flexible composite piezoelectric film and preparation method thereof

A bacterial cellulose, piezoelectric thin film technology, applied to the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, materials for piezoelectric devices or electrostrictive devices Choose other directions, which can solve the problems of increasing the cost of material production, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

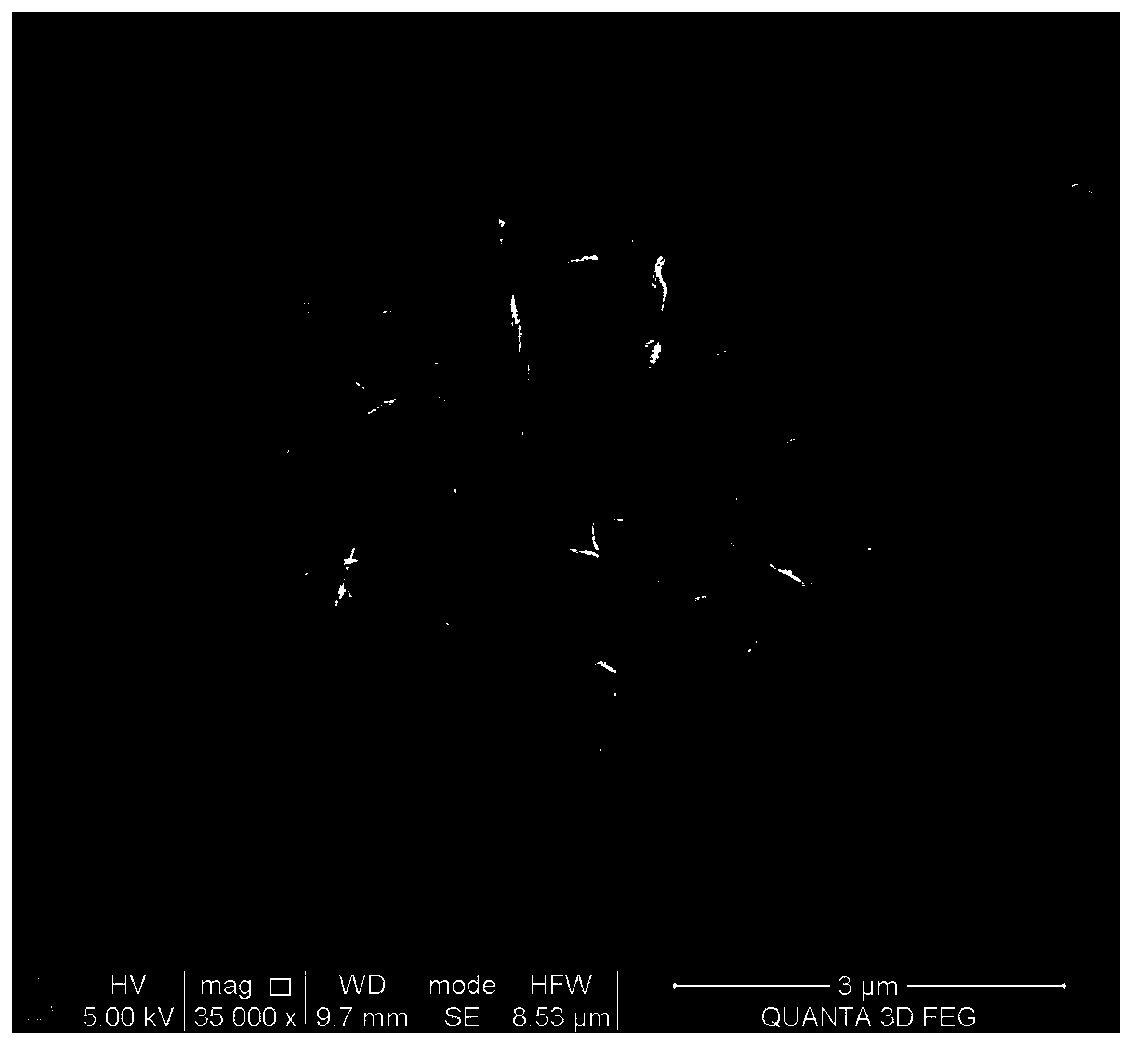

Image

Examples

Embodiment 1

[0030] A preparation method of bacterial cellulose flexible composite piezoelectric film, said method comprising the following steps:

[0031] (1) Prepare a mixed aqueous solution containing zinc acetate and vanadium pentoxide, wherein the concentration of zinc acetate is 50 mM, and the concentration of vanadium pentoxide is 15 mM, and soak the bacterial cellulose wet film in it for 12 hours.

[0032] (2) Prepare an aqueous solution containing zinc acetate and vanadium pentoxide, then mix the aqueous solution containing zinc acetate and vanadium pentoxide with diethylene glycol at a volume ratio of 1:4 to obtain zinc acetate, vanadium pentoxide and diethylene glycol A mixed solution of glycol; in the mixed solution containing zinc acetate, vanadium pentoxide and diethylene glycol, the concentration of zinc acetate is controlled to be 10 mM, and the concentration of vanadium pentoxide is 1mM;

[0033] Immerse the bacterial cellulose soaked in step (1) into a mixed solution cont...

Embodiment 2

[0039] A preparation method of bacterial cellulose flexible composite piezoelectric film, said method comprising the following steps:

[0040](1) Prepare a mixed aqueous solution containing zinc acetate and vanadium pentoxide, wherein the concentration of zinc acetate is 40 mM, and the concentration of vanadium pentoxide is 10 mM, and soak the bacterial cellulose wet film in it for 24 hours.

[0041] (2) Prepare an aqueous solution containing zinc acetate and vanadium pentoxide, then mix the aqueous solution containing zinc acetate and vanadium pentoxide with diethylene glycol at a volume ratio of 1:3 to obtain zinc acetate, vanadium pentoxide and diethylene glycol A mixed solution of glycol; in the mixed solution containing zinc acetate, vanadium pentoxide and diethylene glycol, the concentration of zinc acetate is controlled to be 20mM, and the concentration of vanadium pentoxide is 2mM;

[0042] Immerse the bacterial cellulose soaked in step (1) into a mixed solution contai...

Embodiment 3

[0048] A preparation method of bacterial cellulose flexible composite piezoelectric film, said method comprising the following steps:

[0049] (1) Prepare a mixed aqueous solution containing zinc acetate and vanadium pentoxide, wherein the concentration of zinc acetate is 50 mM, and the concentration of vanadium pentoxide is 5 mM, and soak the bacterial cellulose wet film in it for 48 hours.

[0050] (2) Prepare an aqueous solution containing zinc acetate and vanadium pentoxide, then mix the aqueous solution containing zinc acetate and vanadium pentoxide with diethylene glycol at a volume ratio of 1:4 to obtain zinc acetate, vanadium pentoxide and diethylene glycol A mixed solution of glycol; in the mixed solution containing zinc acetate, vanadium pentoxide and diethylene glycol, the concentration of zinc acetate is controlled to be 10 mM, and the concentration of vanadium pentoxide is 1mM;

[0051] Immerse the bacterial cellulose soaked in step (1) into a mixed solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com