Preparation method of metal and metal oxide quantum dot-mesopore carbon nanometer composite material

A technology of nanocomposite materials and quantum dots, which is applied in the field of preparation of metal and metal oxide quantum dots-mesoporous carbon nanocomposites, can solve the problems of toxicity, cost, and human hazards, and achieve the prevention of agglomeration, convenient operation, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Peel the corn stalks and remove the inner stems, take the inner pulp and pulverize, dry at 60°C for 5 hours, and set aside. Weigh 0.49g of manganese acetate, add 35mL of distilled water and 5mL of ethanol to prepare a 50mmol / L manganese acetate solution. Weigh 0.2 g of the treated corn husks into a 100 mL round bottom flask, add the prepared manganese acetate solution, ultrasonicate for 30 min at room temperature, and vacuum treat for 30 min. Suction filtration once and dry at 80°C. The impregnated and dried corn husks were placed in a tube furnace under an argon atmosphere and roasted for 4 hours at a roasting temperature of 600°C and a heating rate of 5°C / min. Grind the product after cooling.

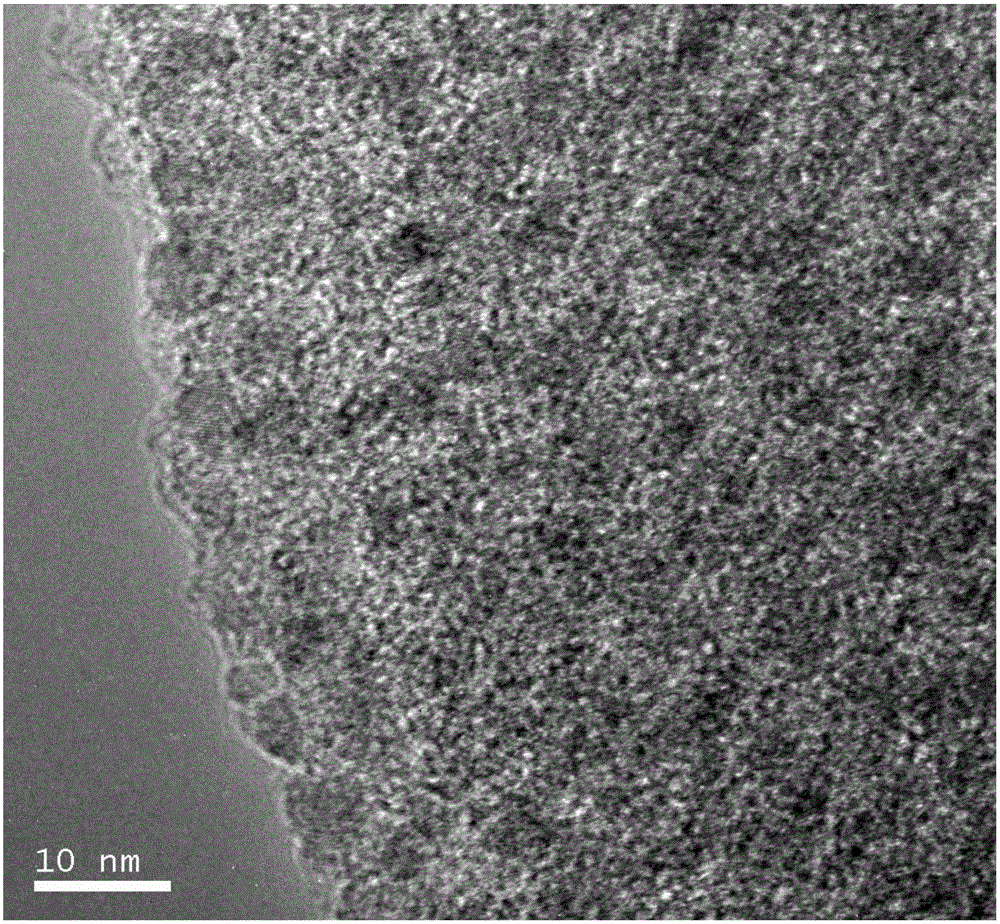

[0038] The obtained manganous oxide quantum dots-mesoporous carbon nanocomposite material was carried out transmission electron microscope detection, the result is as follows figure 1 As shown, the results show that: the quantum dots are highly uniformly dispersed on the mes...

Embodiment 2

[0040] Peel the corn stalks and remove the inner stems, take the inner pulp and pulverize, dry at 60°C for 5 hours, and set aside. Weigh 0.498g of cobalt acetate, add 35mL of distilled water and 5mL of ethanol to prepare a 50mmol / L cobalt acetate solution. Weigh 0.2 g of the treated corn husks into a 100 mL round bottom flask, add the prepared cobalt acetate solution, ultrasonicate for 30 min at room temperature, and vacuum treat for 30 min. Suction filtration once and dry at 80°C. The impregnated and dried corn husks were placed in a tube furnace under an argon atmosphere and roasted for 4 hours at a roasting temperature of 600°C and a heating rate of 5°C / min. Grind the product after cooling.

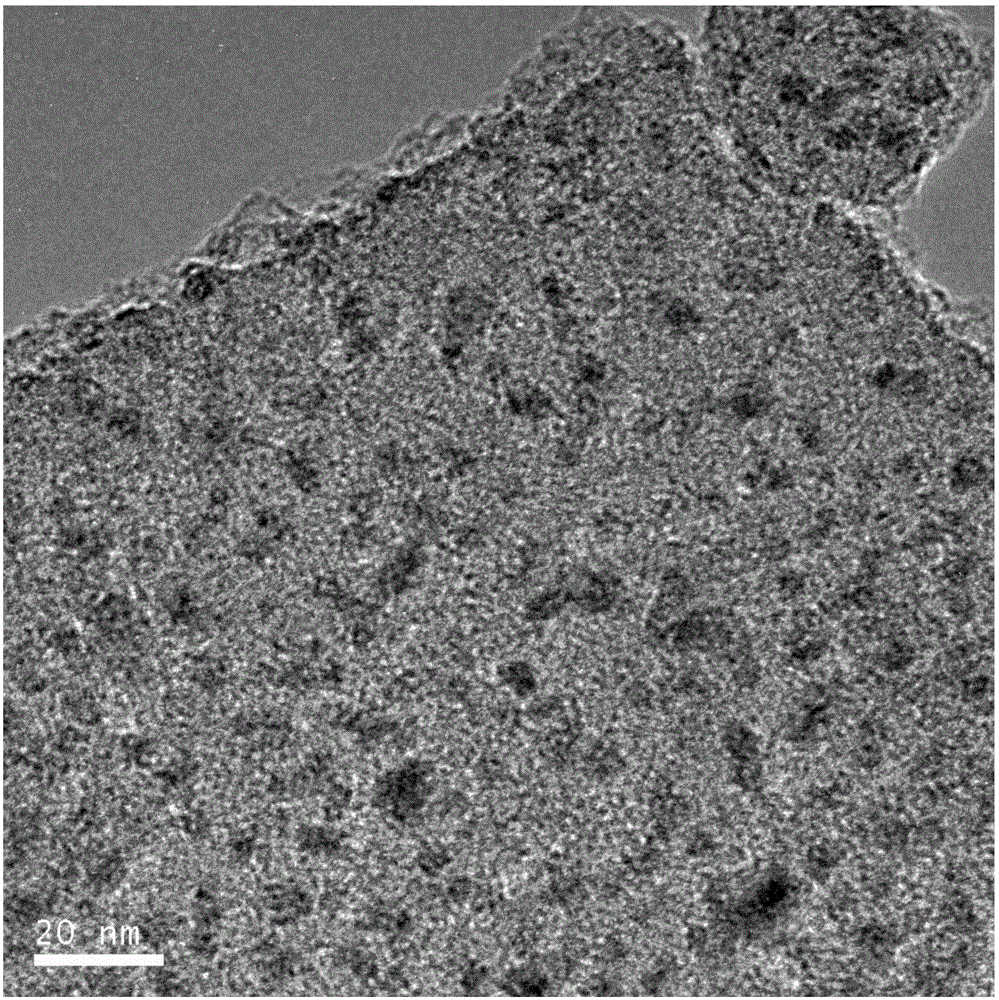

[0041] The obtained cobalt oxide quantum dot-mesoporous carbon nanocomposite material is carried out transmission electron microscope detection, the result is as follows figure 2 As shown, the results show that: the quantum dots are highly uniformly dispersed on the mesoporous carb...

Embodiment 3

[0043] Peel the corn stalks and remove the inner stems, take the inner pulp and pulverize, dry at 60°C for 5 hours, and set aside. Weigh 0.799g of copper acetate, add 35mL of distilled water and 5mL of ethanol to prepare a 100mmol / L copper acetate solution. Weigh 0.2g of the treated corn husks into a 100mL round bottom flask, add the prepared copper acetate solution, ultrasonicate for 30min at room temperature, and vacuum for 30min. Suction filtration once and dry at 80°C. The impregnated and dried corn husks were placed in a tube furnace under an argon atmosphere and roasted for 4 hours at a roasting temperature of 600°C and a heating rate of 5°C / min. Grind the product after cooling.

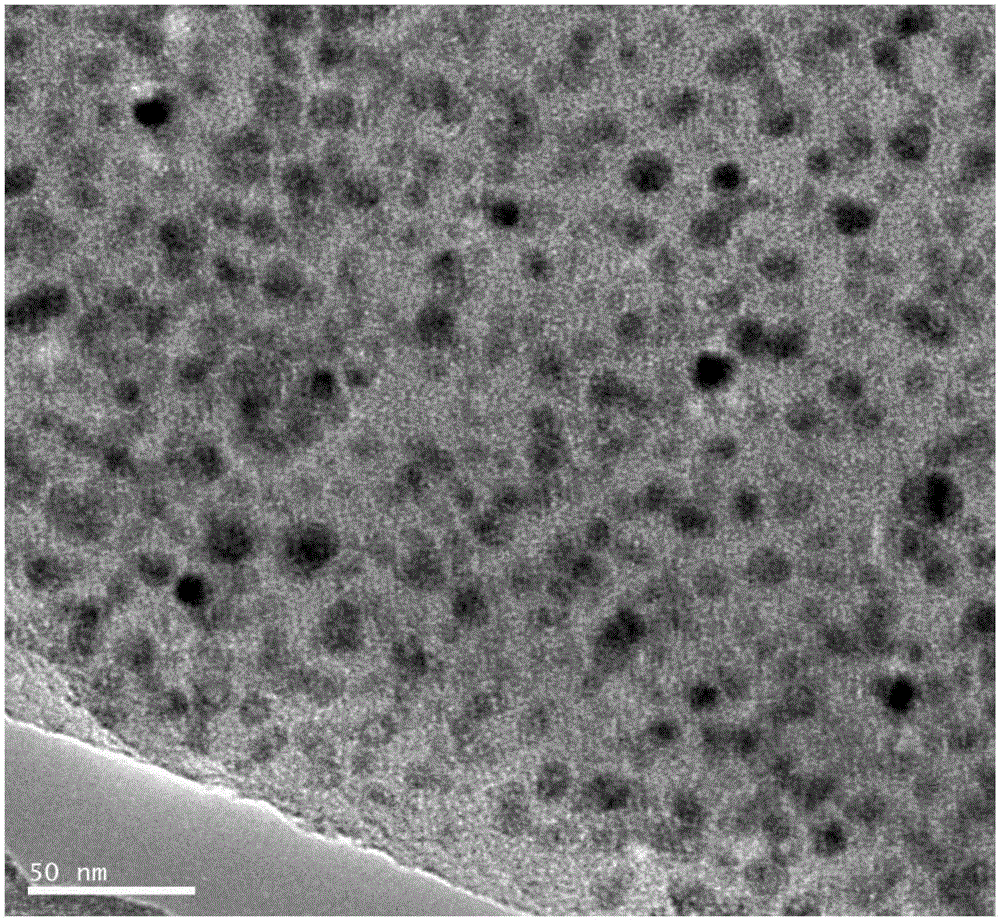

[0044] The obtained copper quantum dot-mesoporous carbon nanocomposite material is carried out transmission electron microscope detection, the result is as follows image 3 As shown, the results show that: the quantum dots are highly uniformly dispersed on the mesoporous carbon, and the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com