Anti-explosion cable and preparation method thereof

A technology of explosion-proof cables and explosion-proof layers, which is applied in the direction of cable/conductor manufacturing, insulated cables, and cables. , bending and other issues, to achieve the effect of improving explosion-proof safety performance, good mechanical performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

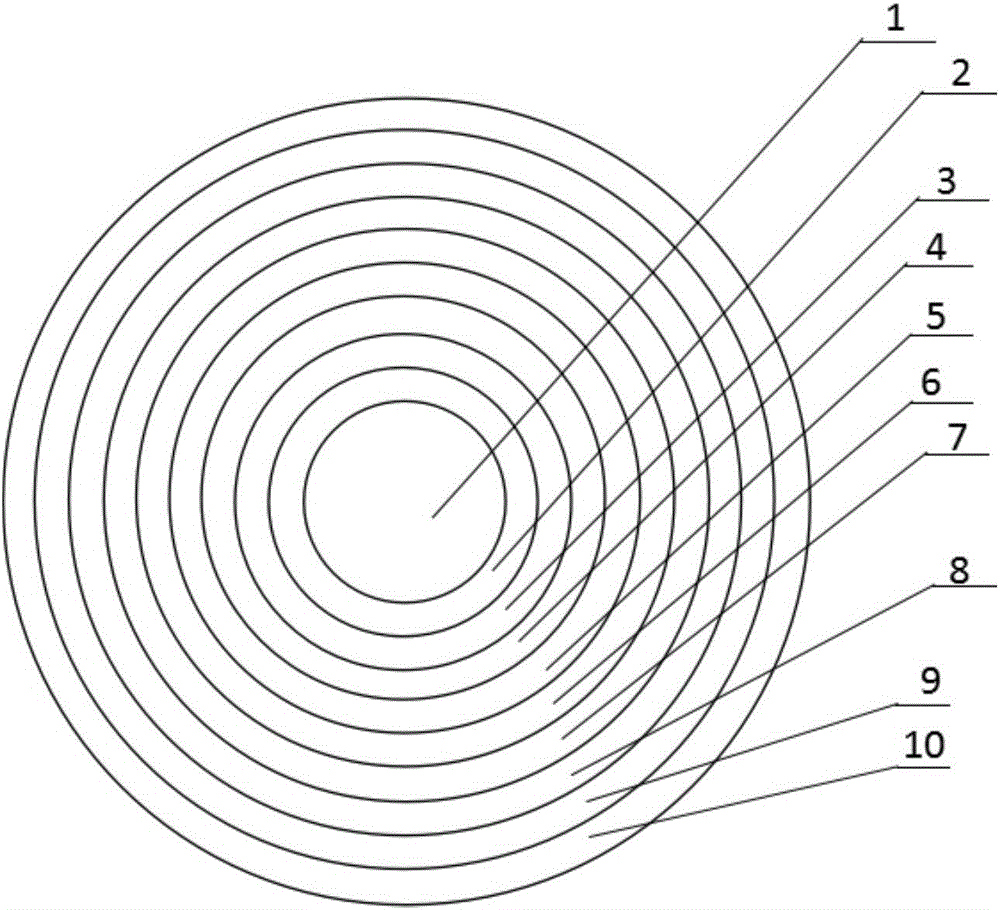

Image

Examples

Embodiment 1

[0026]A preparation method of the above-mentioned explosion-proof cable, comprising the following process: using an extrusion process to coat an insulating layer on the outside of the cable conductor core, then using overlapping wrapping to form a shielding layer, and then adhering a phase-change material layer on the outside of the shielding layer. The phase change material layer is coated with a water-blocking layer, and the water-blocking layer is coated with the first explosion-proof layer by extrusion technology, and the compression-resistant layer and the second explosion-proof layer are sequentially coated on the first explosion-proof layer, using a double extrusion process The second explosion-proof layer is coated with a flame-retardant layer and a sheath layer to form an explosion-proof cable;

[0027] The first explosion-proof layer is a rubber explosion-proof layer, and the rubber explosion-proof layer is made by extrusion of materials prepared by the following meth...

Embodiment 2

[0029] The first explosion-proof layer is a rubber explosion-proof layer, and the rubber explosion-proof layer is made by extruding the material prepared by the following method, which includes the following process: by weight, 120 parts of styrene-butadiene rubber is added to a rubber mixer and mixed for 15 Minutes, then add 15 parts of antimony trioxide, 5 parts of carbon black, 8 parts of nano silicon oxide, 5 parts of modified clay and 10 parts of pitch-based carbon fiber, mix well, knead for 2 hours, then add 3 parts of acetyl citric acid Tri-n-butyl ester, 12 parts of isothiazolinone, 5 parts of carboxymethyl cellulose, 5 parts of methyl anthranilate, 8 parts of simethicone, 3 parts of melamine cyanurate, 5 parts of triethanolamine and 5 parts part polylactic acid, mixed for 60 minutes to obtain a rubber material, and molded the rubber material to obtain a rubber material for preparing a rubber explosion-proof layer.

[0030] Other processes and parameters are exactly th...

Embodiment 3

[0032] The first explosion-proof layer is a rubber explosion-proof layer, and the rubber explosion-proof layer is made by extruding the material prepared by the following method, which includes the following process: by weight, 110 parts of styrene-butadiene rubber is added to a rubber mixer and mixed for 12 Minutes, then add 12 parts of antimony trioxide, 4 parts of carbon black, 6 parts of nano silicon oxide, 4 parts of modified clay and 8 parts of pitch-based carbon fiber, mix well, knead for 1.5 hours, then add 2 parts of acetyl citric acid Tri-n-butyl ester, 10 parts of isothiazolinone, 4 parts of carboxymethyl cellulose, 4 parts of methyl anthranilate, 6 parts of simethicone, 2 parts of melamine cyanurate, 4 parts of triethanolamine and 4 parts part polylactic acid, mixed for 40 minutes to obtain a rubber material, and molded the rubber material to obtain a rubber material for preparing a rubber explosion-proof layer.

[0033] Other processes and parameters are exactly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com