A surface-enhanced Raman substrate and its preparation method

A surface-enhanced Raman and substrate technology, applied in Raman scattering, nanotechnology for materials and surface science, material excitation analysis, etc., can solve problems such as high cost, unsuitable for large-scale industrial production, and cumbersome processes. Achieve controllable process, significant Raman enhancement effect, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Use magnetron sputtering to coat a layer of 200nm silver film on the silicon wafer to obtain a silver-coated silicon wafer;

[0058] 2) Put the silver-coated silicon wafer obtained in 1) into the ICP chamber of an inductively coupled plasma etching machine, and feed 30 sccm of working gas, wherein the working gas is composed of Cl with a volume ratio of 2:1. 2 and Ar, adjust the cavity pressure to 0.4Pa, set the power of the upper electrode to 500W, and set the power of the lower electrode to 60W, and maintain it for 30s to obtain a surface-enhanced Raman substrate.

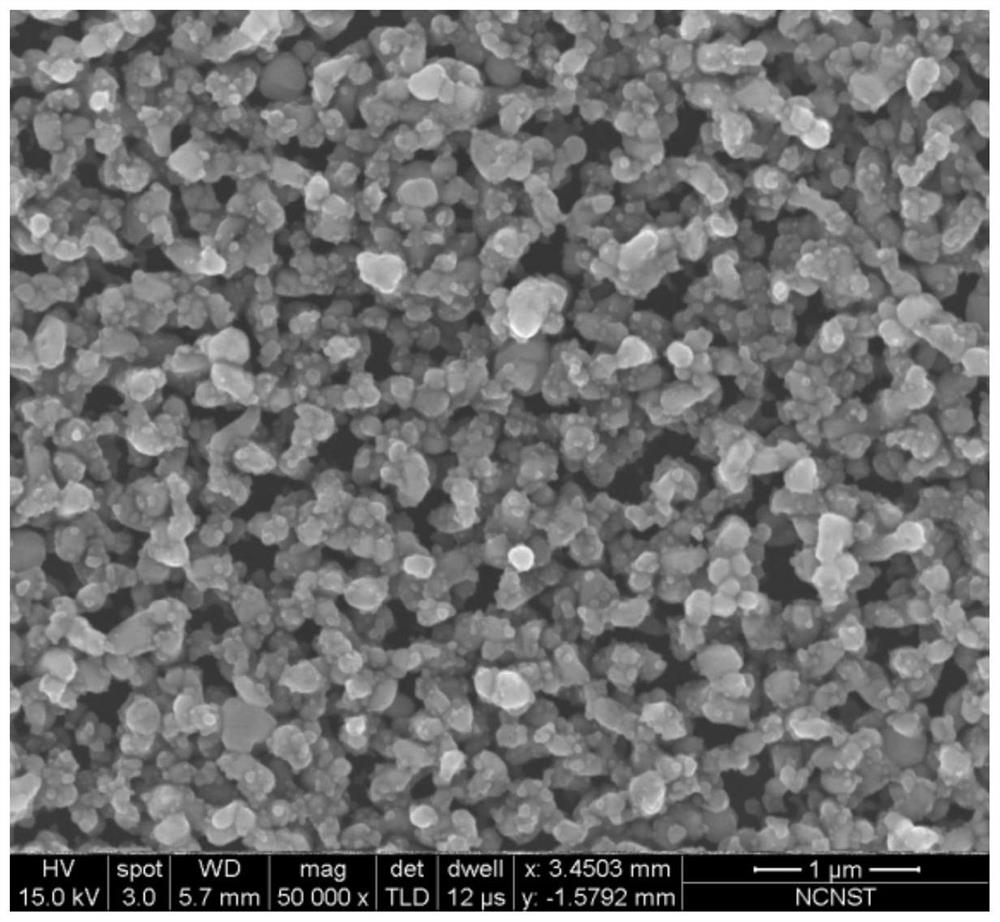

[0059] From figure 1 and figure 2 It can be seen that the surface of the surface-enhanced Raman substrate obtained in Example 1 forms a porous nano-silver film composed of nano-silver particles with a median diameter of about 30 nm uniformly dispersed on the surface of the silicon wafer.

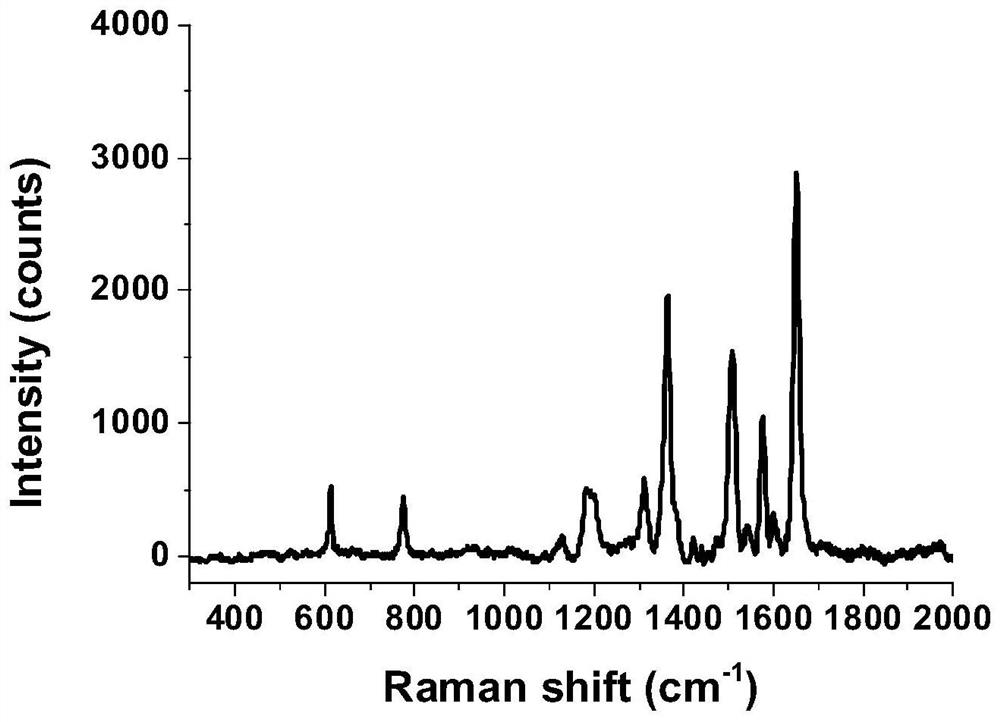

[0060] Take out the sample piece and modify the rhodamine 6G molecule: at 10 -7 Soak in mol / L rhodamine 6G solu...

Embodiment 2

[0064] 1) Use magnetron sputtering to plate a layer of 500nm silver film on the silicon wafer to obtain a silver-coated silicon wafer;

[0065] 2) Put 1) gained silver-coated film silicon chip into the ICP chamber of inductively coupled plasma etching machine, pass into the Cl of 50sccm 2 , the chamber pressure is 1Pa, the power of the upper electrode is set to 1000W, the power of the lower electrode is set to 100W, and it is maintained for 15s. The obtained surface-enhanced Raman substrate has high sensitivity and can realize single-molecule detection.

Embodiment 3

[0066] The difference between embodiment 3 and embodiment 2 is only that the etching time is 30s.

[0067] From Figure 4 and Figure 5 It can be seen that the surface of the surface-enhanced Raman substrate obtained in Example 3 forms a porous nano-silver film composed of nano-silver particles with a median diameter of about 40 nm uniformly dispersed on the surface of the silicon wafer. This surface-enhanced Raman substrate has high sensitivity and can realize single-molecule detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com