Low-pressure oil duct fuel injection valve

A technology for fuel injection valves and oil passages, which is applied in the field of fuel injection valves and engine fuel injection valves. Improvement of response speed and improvement of injection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

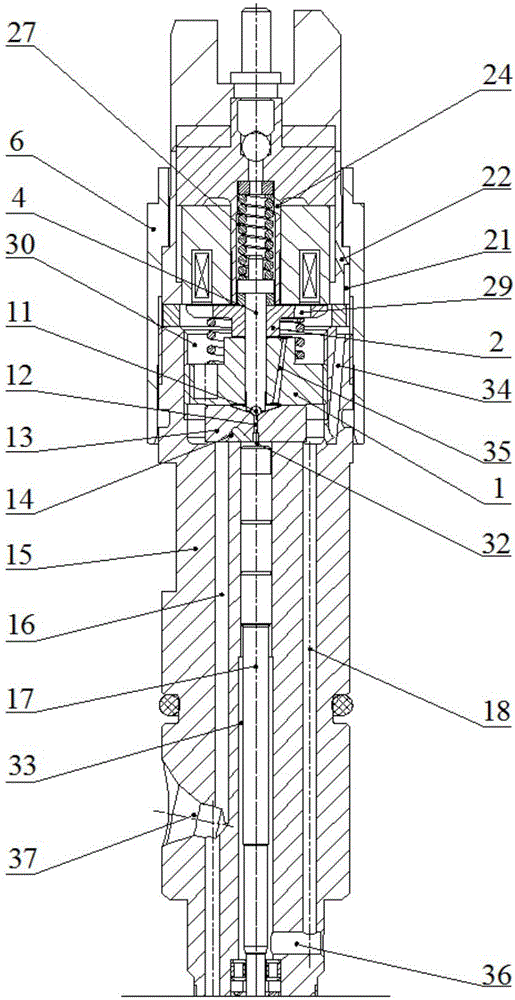

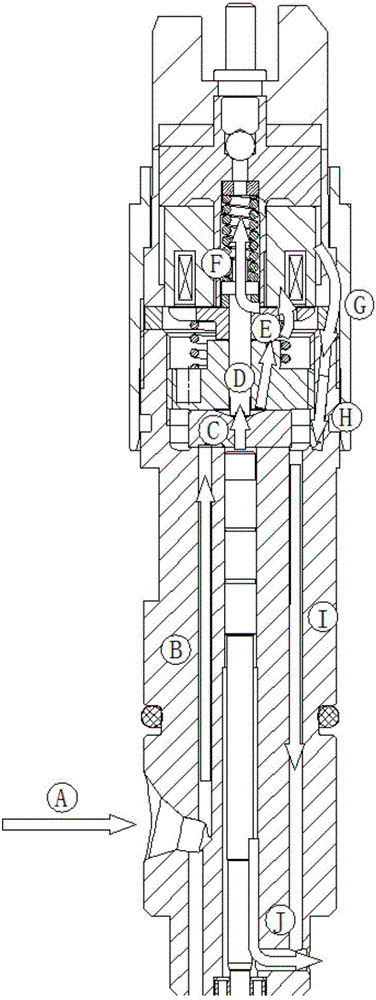

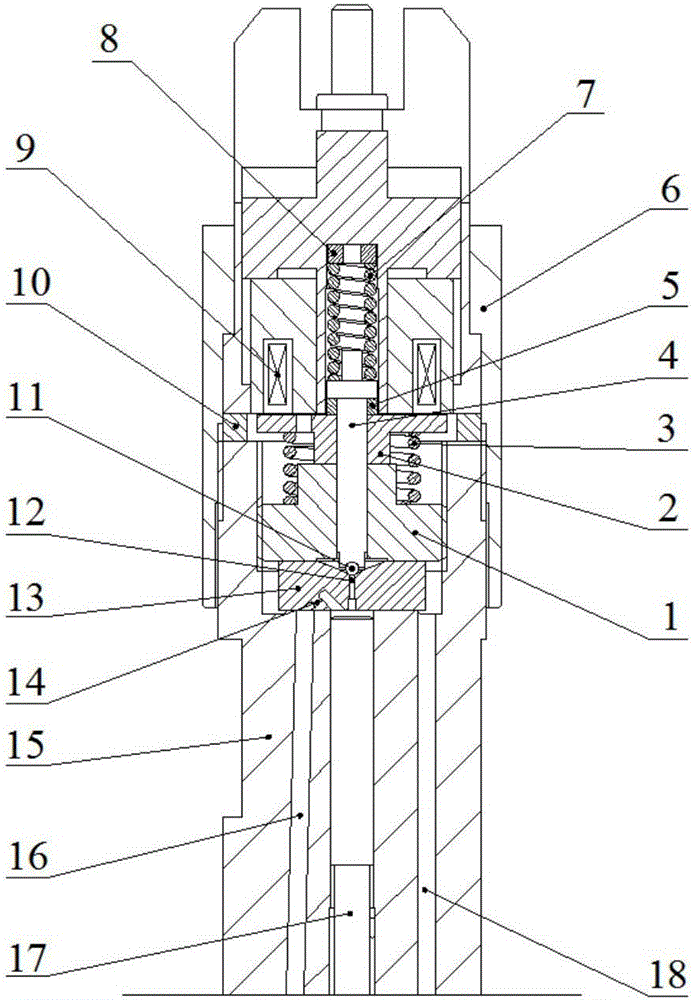

[0046] The direction of the low-pressure oil circuit in Embodiment 1 is as follows: after the electromagnet is energized, the armature 2 is attracted to drive the armature rod 4 and the steel ball 11 to move upwards, and the high-pressure oil in the piston chamber 33 is controlled to be released from the oil outlet orifice 12. The control valve seat drainage groove 38 on the bottom surface of the control valve seat 1 flows into the throttle orifice chamber 43. Since the main oil return hole 18 directly communicates with the outside world, the pressure in the hole is relatively low, and the oil return in the throttle orifice chamber 43 takes advantage of the trend from the main oil return hole. The oil hole 18 drains downward, and directly discharges the fuel injector. During the working process of the injector, the high-pressure oil stored in the upper cavity of the control piston cavity 33 will leak into the lower cavity of the control piston cavity 33 through the coupling gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com