Gas-assisted type metered injection system and control method thereof

A gas-assisted and injection system technology, which is applied to the electronic control, exhaust treatment, and exhaust devices of exhaust gas treatment devices, can solve the problems of reduced injection accuracy of urea solution and easy crystallization of urea solution, and achieves improved effect and injection. Accuracy, improve jetting accuracy and reliability, avoid the effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

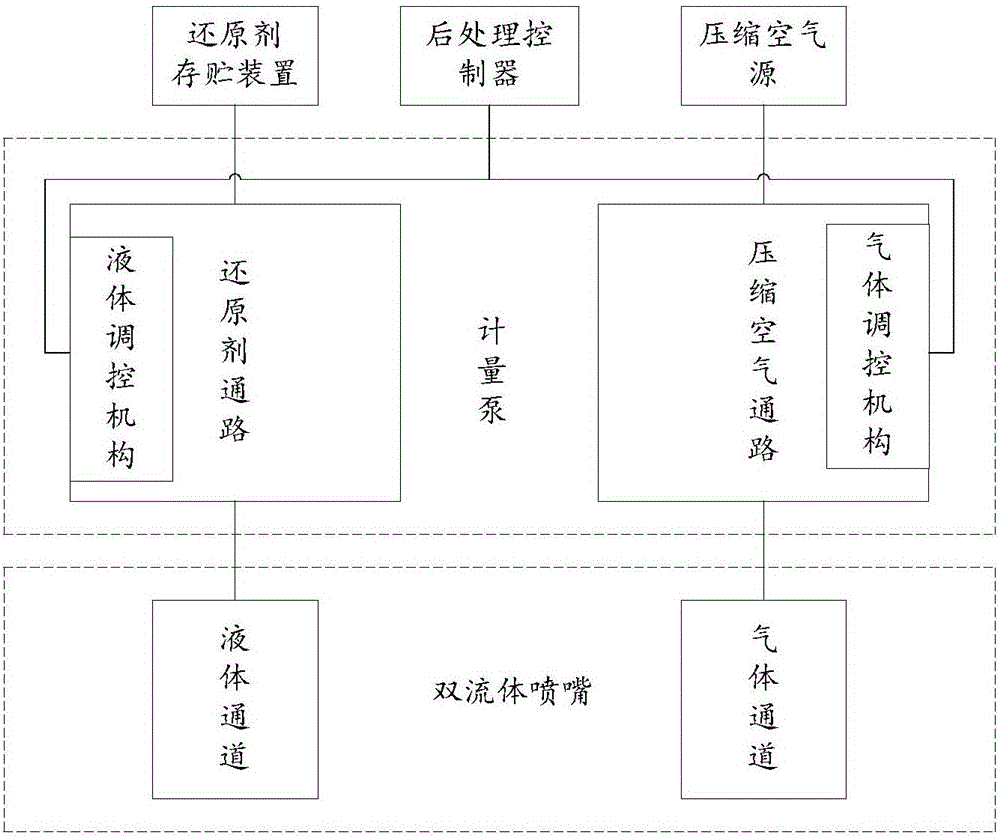

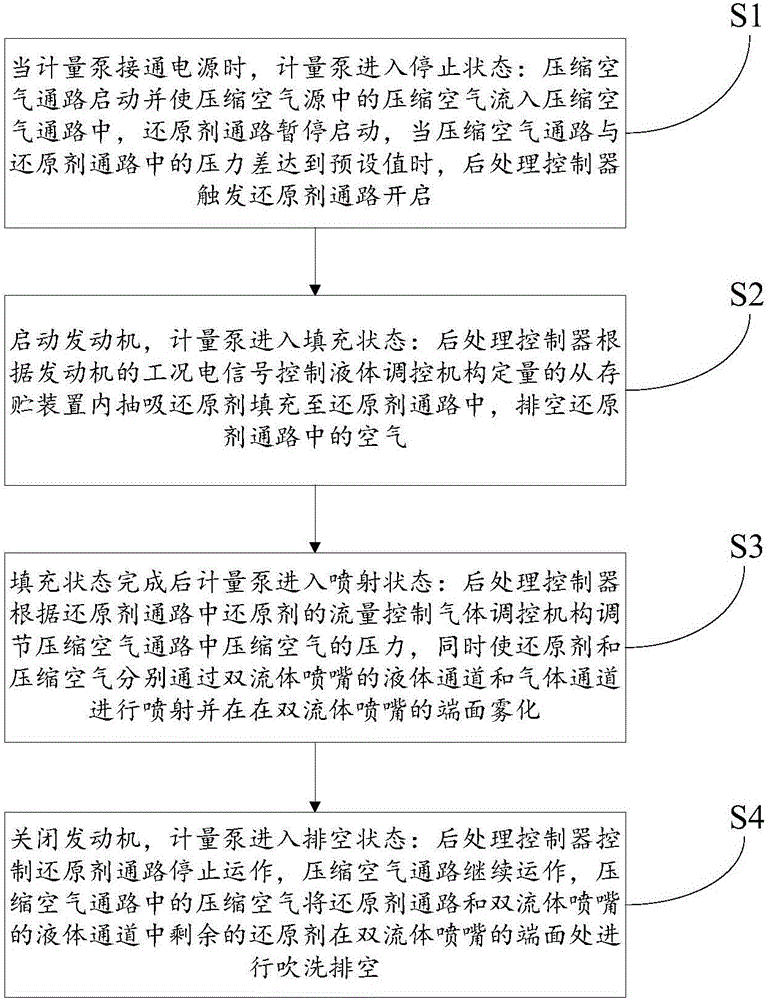

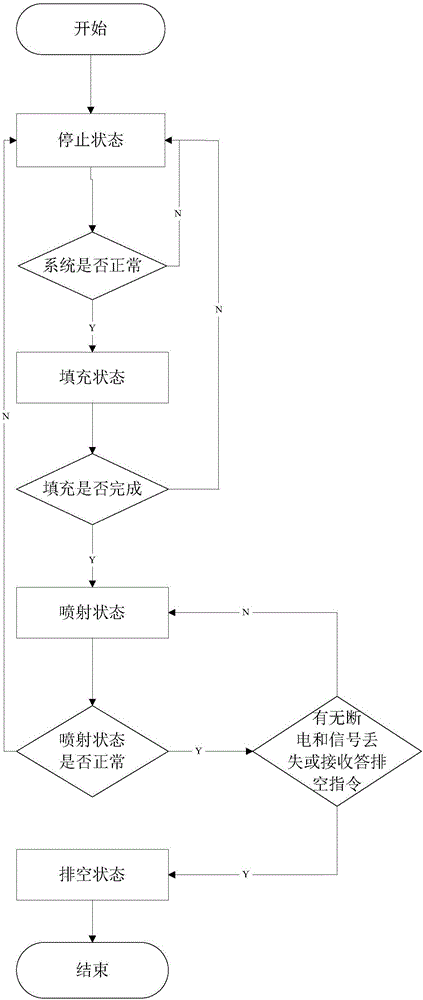

[0034] Such as figure 1As shown, a gas-assisted metering injection system includes a metering pump, a two-fluid nozzle, a reducing agent storage device, a compressed air source, and an aftertreatment controller. The metering pump is provided with independent reducing agent passages and compression An air passage, the inlet of the reducing agent passage is connected to the reducing agent storage device, the inlet of the compressed air passage is connected to the compressed air source, and the outlet of the reducing agent passage and the outlet of the compressed air passage respectively correspond to The liquid passage and the gas passage of the two-fluid nozzle are connected, a liquid regulation mechanism is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com