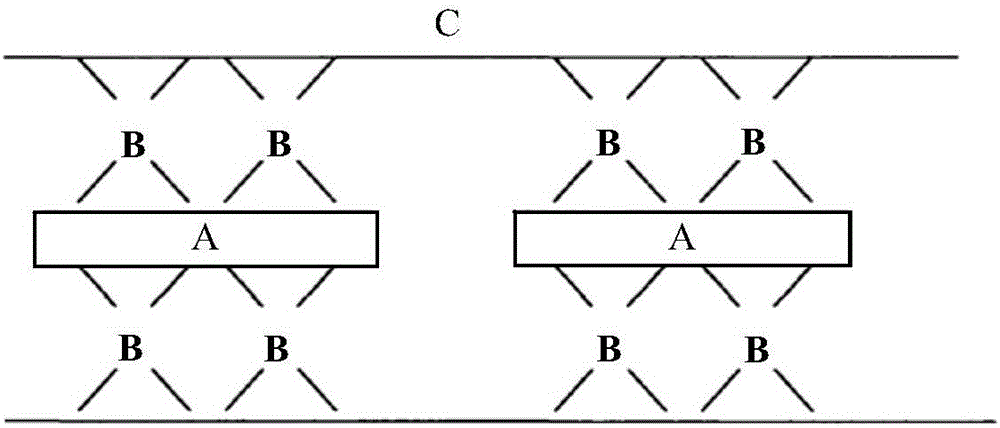

Modified precipitated calcium carbonate prepared by crosslinking konjac gum on surface through organic boron, preparation method and application thereof and paper

A technology of precipitating calcium carbonate and cross-linking modification, applied in chemical instruments and methods, dyeing low-molecular-weight organic compound treatment, dyeing high-molecular-weight organic compound treatment, etc. Uniform, retention-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Step 1: Add 1% (relative to the amount of PCC added) konjac gum into the oblique three mouths containing 90g of water, heat up to 50°C, stir and disperse at 400rpm, and then add 10g of PCC;

[0067] Step 2: Add 4% (relative to the amount of PCC added) triethanolamine borate into the reactor, and stir for 60 minutes;

[0068] Step 3: collecting the reaction product by centrifugation and washing and drying it;

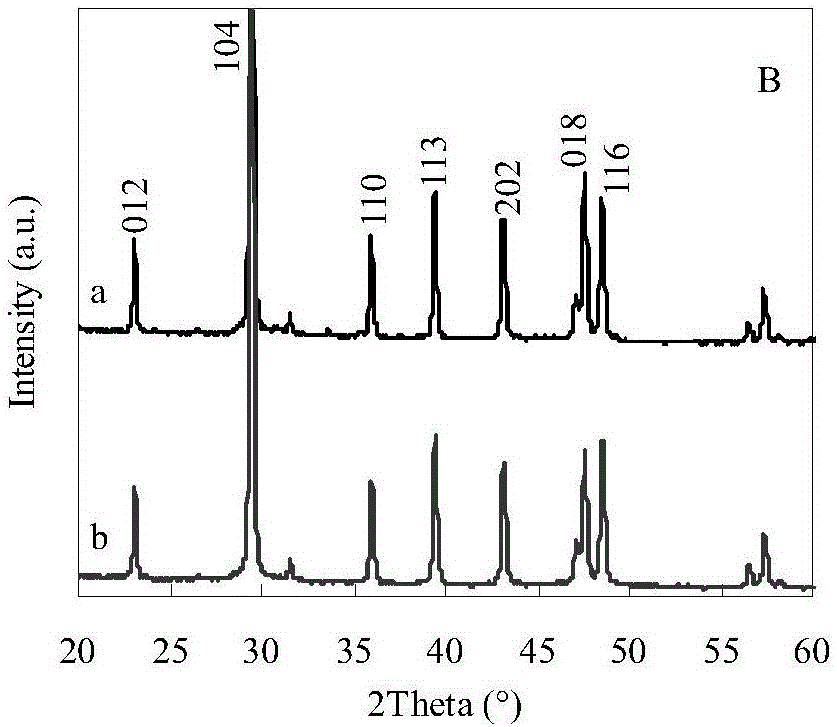

[0069] Step 4: Grind MPCC and PCC finely with a mortar, pass through a 200-mesh copper mesh, analyze and characterize them with a scanning electron microscope, Fourier transform infrared spectrometer, elemental analyzer, etc. respectively.

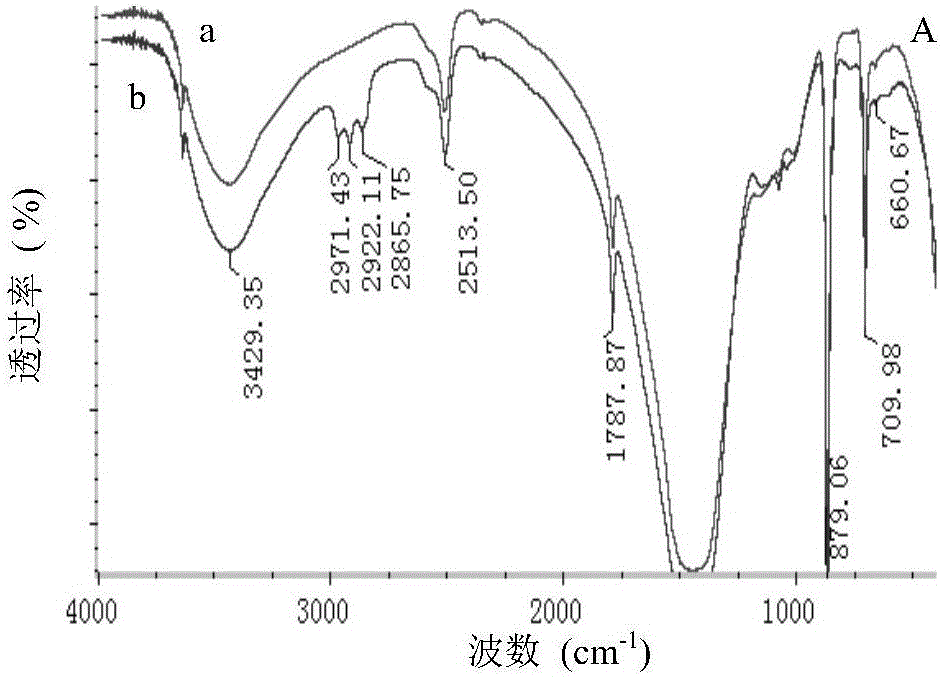

[0070] The Magna IR 560 Fourier Transform Infrared Spectrometer produced by Nicolet Company of the United States was used for measurement, and the scanning range was 400 to 4000 cm -1 , scanning speed 40 times / min. The KBr tablet method is used to prepare the sample. Take an appropriate amount of the powder to be tested and ...

Embodiment 2

[0082] Step 1: Add 1% (relative to the amount of PCC added) konjac gum into the oblique three mouths containing 90g of water, heat up to 50°C, stir and disperse at 400rpm, and then add 10g of PCC;

[0083] Step 2: Add 4% (relative to the amount of PCC added) triethanolamine borate into the reactor, and stir for 60 minutes;

[0084] Step 3: collecting the reaction product by centrifugation and washing and drying it;

[0085] Step 4: Thaw the bleached kraft pulp soaked in water for more than 4 hours with a standard deflaker, use a beater to beat to 37°SR, add MPCC and PCC respectively after appropriate dilution, and the filling amount is 20% (based on the dry pulp amount ); refer to the GB / T3703-1999 method, papermaking in a sheet former; after pressing for 1 min at a pressure of 0.4 MPa in a hydraulic press, dry in a dryer at 97°C for 5 min, and the quantitative value of the hand-sheet is 70 g / m 2 ;

[0086] Step 5: After drying the two hand-sheets obtained in Step 4, take a ...

Embodiment 3

[0089] Step 1: Add konjac gum to the three oblique mouths containing 90g of water, heat up to 80°C, stir and disperse at 400rpm, then add 10g of PCC; the amount of konjac gum is as follows Figure 8-Figure 11 As shown, its dosage is respectively: 0.5%, 1%, 1.25%, 1.75%, 2%, 3%, 4%, 5%, 6%, 7% (relative to the amount of PCC added);

[0090] Step 2: Add 10% (relative to the amount of PCC added) triethanolamine borate into the reactor, and stir for 60 minutes;

[0091] Step 3: collecting the reaction product by centrifugation and washing and drying it;

[0092] Step 4: Decompose the bleached kraft pulp soaked in water for more than 4 hours with a standard decomposer, use a beater to beat to 37°SR, add MPCC after appropriate dilution, and the filling amount is 20% (based on the dry pulp volume); refer to According to the method of GB / T3703-1999, the paper is made in a sheet forming machine; after pressing for 1 min at a pressure of 0.4 MPa in a hydraulic press, it is dried in a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com