Biological enzyme scouring and bleaching agent and scouring and bleaching method for scouring and bleaching roving

A bio-enzyme and bleaching technology, applied in the field of roving bleaching with bio-enzyme bleaching agent and supercritical carbon dioxide as the medium, can solve the problems of high pollution and high energy consumption, and achieve the effect of important theoretical significance and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

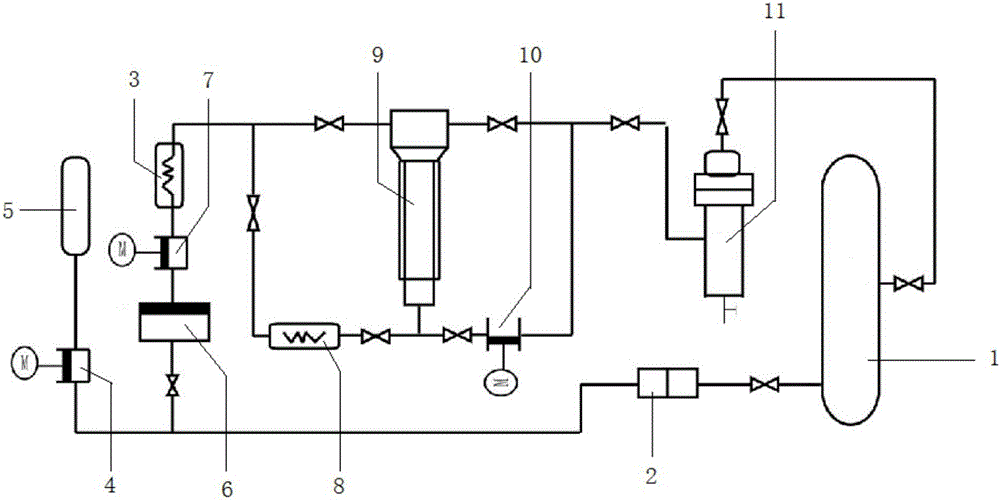

[0044] A method for scouring and bleaching of rovings, the method uses a biological enzyme decoction and bleaching agent as a decoction and bleaching agent, uses supercritical carbon dioxide as a medium, and adopts a supercritical carbon dioxide decoction and bleaching device for decoction and bleaching. The device is as follows: figure 1 .

[0045] Such as figure 1 The shown supercritical carbon dioxide bleaching device, including CO 2 Storage tanks, bleaching tanks, co-solvent tanks, separation tanks, liquid transfer pumps, ultrasonic atomizers, CO 2 Booster pump, heater, magnetic circulation pump.

[0046] The connection relationship and the working principle when using the device to boil and bleach are: CO 2 in CO 2 In the storage tank, the flax roving is placed in the bleaching kettle, and the biological enzyme bleaching agent is placed in the co-solvent tank. During the blanching process, the refrigeration system is first turned on, and the liquid CO 2 in CO 2 The...

Embodiment 2

[0054] A method for bleaching and bleaching roving by using a supercritical carbon dioxide bioenzyme bleaching agent, adopting such as figure 1 The shown supercritical carbon dioxide decoction bleaching device, the method comprises the steps:

[0055] (1) Preparation of biological enzyme bleaching agent: the biological enzyme solution of Cellulomonas, Trichoderma reesei, Bacillus cereus, Pseudomonas fluorescens and Aspergillus niger ASP-12 obtained by the above method according to the volume ratio of 1 : 1:2:2:3 mix, stir evenly, set aside;

[0056] (2) 10kg flax roving bobbins are put into the bleaching kettle, and the biological enzyme bleaching agent is put into the co-solvent tank;

[0057] (3) Turn on the refrigeration system, liquid CO 2 from CO 2 The outflow from the storage tank flows into the ultrasonic atomizer; open the co-solvent tank, under the action of the liquid delivery pump, the biological enzyme bleaching agent enters the ultrasonic atomizer through the c...

Embodiment 3

[0061] A method for bleaching and bleaching roving by using a supercritical carbon dioxide bioenzyme bleaching agent, adopting such as figure 1 The shown supercritical carbon dioxide decoction bleaching device, the method comprises the steps:

[0062](1) Preparation of biological enzyme bleaching agent: the biological enzyme solution of Cellulomonas, Trichoderma reesei, Bacillus cereus, Pseudomonas fluorescens and Aspergillus niger ASP-12 obtained by the above method according to the volume ratio of 1 : 3:2:1:7 mix, stir evenly, set aside;

[0063] (2) 5kg ramie roving bobbins are put into the bleaching kettle, and the biological enzyme bleaching agent is put into the co-solvent tank;

[0064] (3) Turn on the refrigeration system, liquid CO 2 from CO 2 The outflow from the storage tank flows into the ultrasonic atomizer; open the co-solvent tank, under the action of the liquid delivery pump, the biological enzyme bleaching agent enters the ultrasonic atomizer through the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com