Method for performing supercritical carbon dioxide bio-enzyme scouring/bleaching/dyeing on bast fiber coarse yarns

A carbon dioxide and supercritical technology, applied in the textile field, can solve the problems of high water consumption, scouring and bleaching of hemp fiber roving and high pollution in the dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086]Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:1:1 to form a compound biological enzyme solution with a concentration of 1%, stir evenly and set aside.

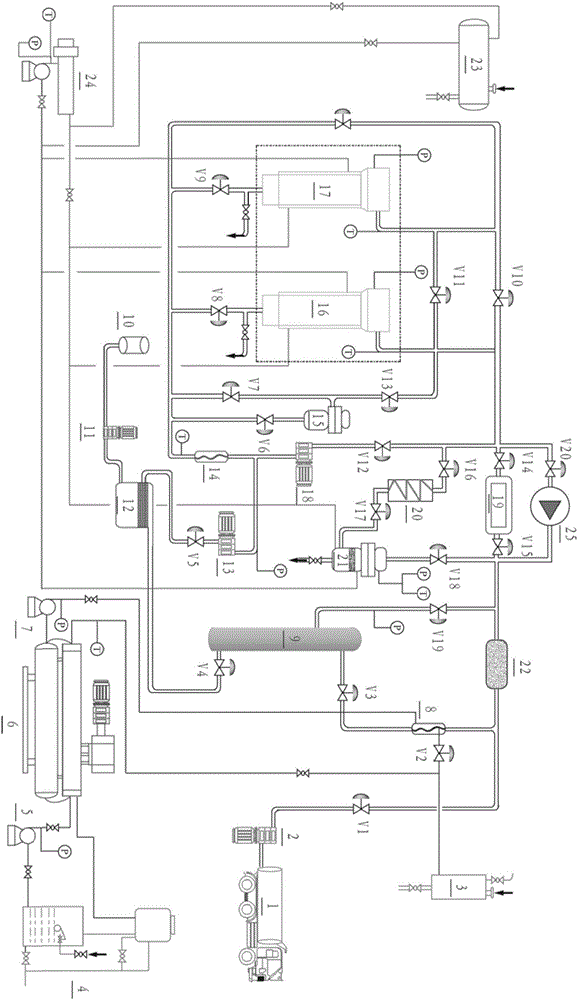

[0087] Put 10kg flax roving, 1% (o.w.f.) of disperse dye and 1% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 in sequence; open gas storag...

Embodiment 2

[0091] Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:1:3 to form a compound biological enzyme solution with a concentration of 4%, stir evenly and set aside.

[0092] Put 15kg ramie roving, 2% (o.w.f.) of reactive disperse dyes and 4% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 successively; op...

Embodiment 3

[0096] Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:2:3 to form a compound biological enzyme solution with a concentration of 3%, stir evenly and set aside.

[0097] Put 20kg hemp roving, reactive dye 1.5% (o.w.f.) and concentration 3% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 successively; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com