SnO2/TiO2 composite nanofiber photocatalyst and preparation method thereof

A composite nanofiber and photocatalyst technology, which is applied in the field of polymer materials and photocatalysis, can solve the problems of difficult control of process parameters, complex process, and many process parameters, so as to improve photocatalytic activity, optimize preparation process, and simplify process parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

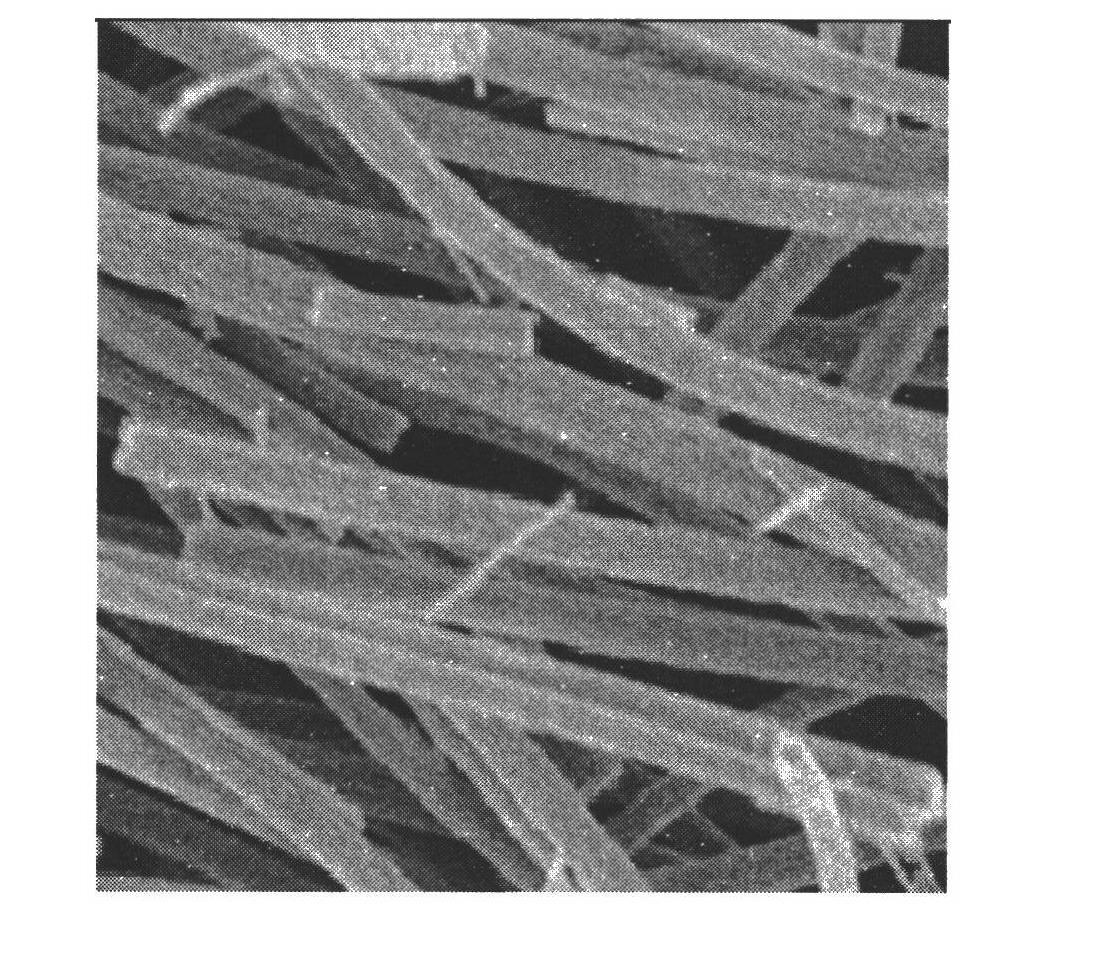

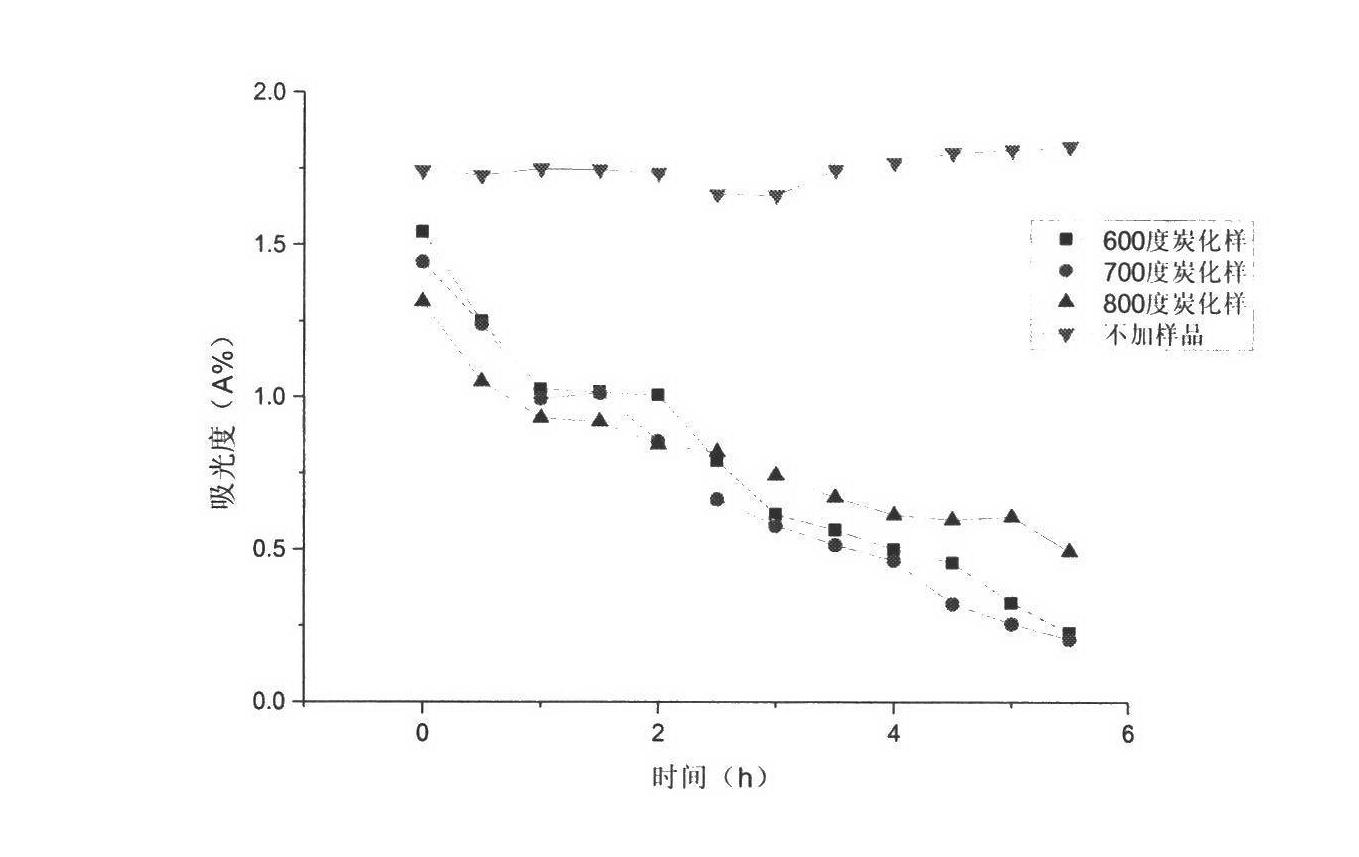

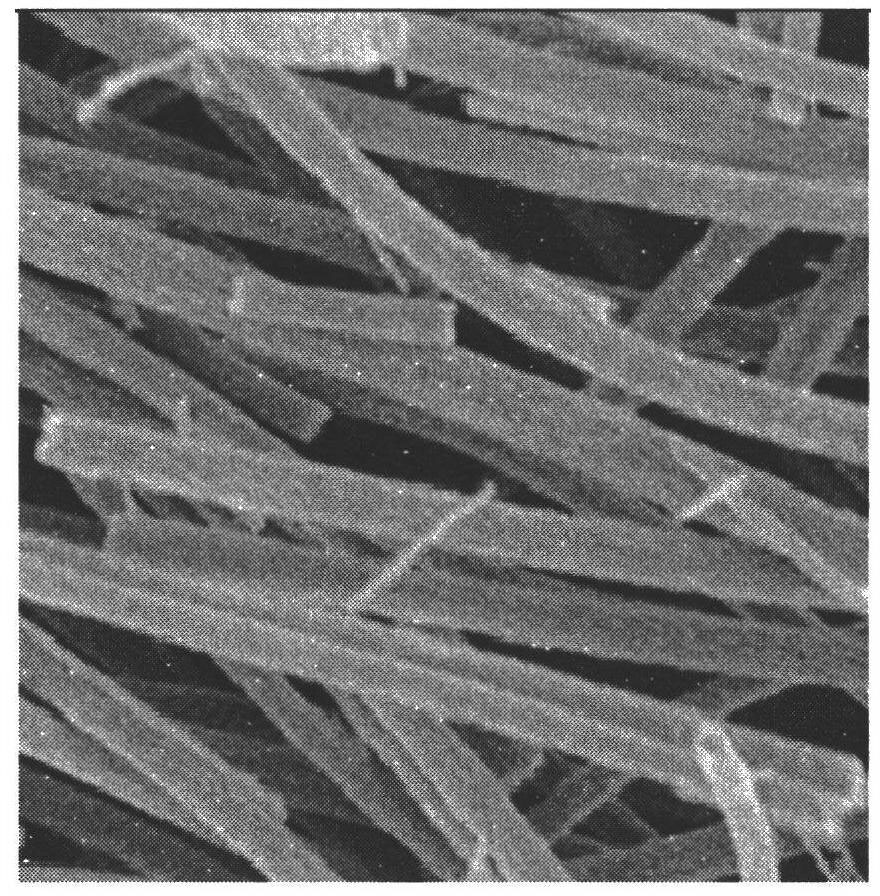

[0018] Weigh 1.5g PVP and dissolve in 8.5g DMF, then weigh 1.745g SnCl 4 .5H 2 O into it, then press SnCl 4 .5H 2 O and tetra-n-butyl titanate (TBT) molar ratios of 1:1, 1:3, 1:5, 1:7, 3:1 were added to the above solution with TBT, and stirred with a magnetic stirrer at room temperature for 6 ~8h to complete dissolution to obtain a transparent solution. The prepared above-mentioned spinning solution is packed into a syringe with a ground stainless steel needle, and the syringe is installed on the electrospinning device. At a spinning voltage of 10kV, the distance between the receiving device and the spinneret is 15cm, and the spinning Under the process condition of liquid flow rate of 0.5mL / h, the nanofiber membrane was obtained by spinning for 10h. The obtained nanofibrous membrane was put into a muffle furnace, the temperature was raised from room temperature to 600 °C at a rate of 1 °C / min, calcined for 5 h, and then naturally cooled to room temperature.

Embodiment 2

[0020] Weigh 1.5g PVP and dissolve in 8.5g DMF, then weigh 1.745g SnCl 4 .5H 2 O into it, then press SnCl 4 .5H 2 O and tetra-n-butyl titanate (TBT) molar ratios of 1:1, 1:3, 1:5, 1:7, 3:1 were added to the above solution with TBT, and stirred with a magnetic stirrer at room temperature for 6 ~8h to complete dissolution to obtain a transparent solution. The prepared above-mentioned spinning solution is packed into a syringe with a ground stainless steel needle, and the syringe is installed on the electrospinning device. At a spinning voltage of 15kV, the distance between the receiving device and the spinneret is 20cm, and the spinning Under the process condition of liquid flow rate of 1.0mL / h, the nanofibrous membrane was obtained by spinning for 10h. The obtained nanofibrous membrane was put into a muffle furnace, heated from room temperature to 600 °C at a rate of 2 °C / min, calcined for 3 h, and then naturally cooled to room temperature.

Embodiment 3

[0022] Weigh 1.5g PVP and dissolve in 8.5g DMF, then weigh 1.745g SnCl 4 .5H 2 O into it, then press SnCl 4 .5H 2O and tetra-n-butyl titanate (TBT) molar ratios of 1:1, 1:3, 1:5, 1:7, 3:1 were added to the above solution with TBT, and stirred with a magnetic stirrer at room temperature for 6 ~8h to complete dissolution to obtain a transparent solution. The prepared above-mentioned spinning solution is packed into a syringe with a ground stainless steel needle, and the syringe is installed on the electrospinning device. At a spinning voltage of 20kV, the distance between the receiving device and the spinneret is 25cm, and the spinning Under the process condition of liquid flow rate of 1.5mL / h, the nanofibrous membrane was obtained by spinning for 10h. The obtained nanofibrous membrane was put into a muffle furnace, the temperature was raised from room temperature to 700 °C at a heating rate of 5 °C / min, calcined for 2 h, and then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com