Ice-resistant fabric containing polytetrafluoroethylene

A polytetrafluoroethylene and fabric technology, applied in the field of textile fabrics, can solve problems such as stiffness, hardness, low strength, small mutual attraction, and easy creep, etc., achieve good air permeability, good ice resistance, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

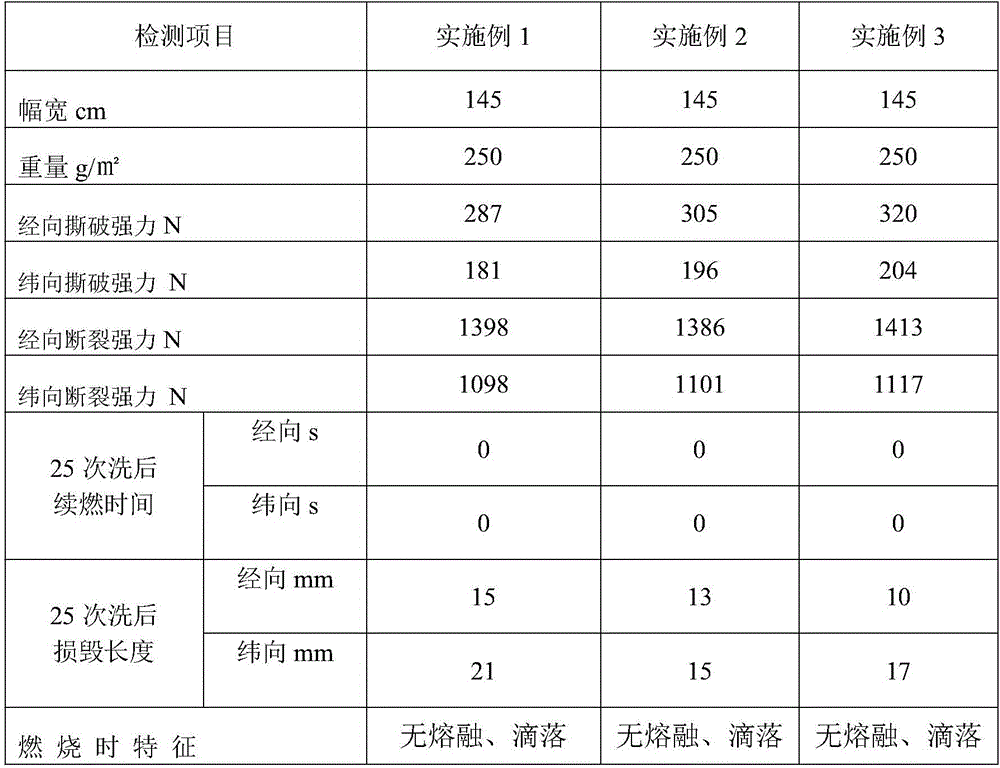

[0045] Embodiment 1 anti-icing fabric containing polytetrafluoroethylene

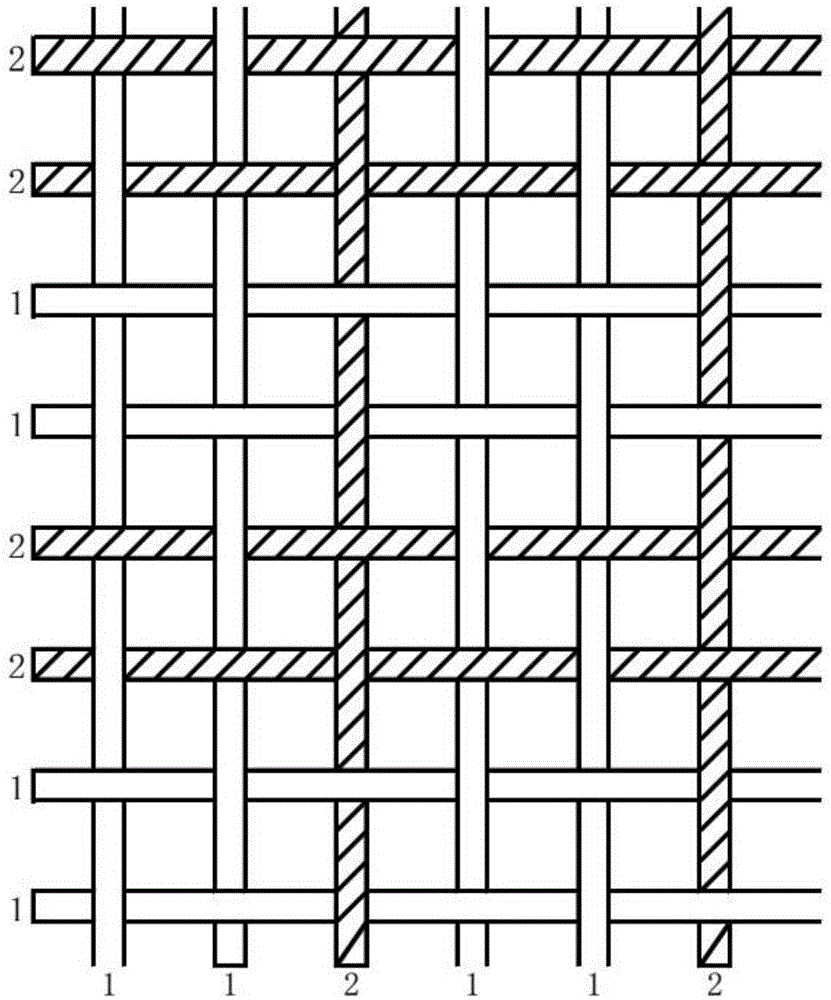

[0046] The ice-resistant fabric provided in this embodiment includes PTFE filaments and aramid fibers, wherein the fabric is formed by interweaving warp and weft in a plain weave pattern with PTFE filaments and aramid fibers at a weight ratio of 10:1.

[0047] Specifically, warp direction: the first warp yarn is 600 denier PTFE filament yarn, every third warp yarn is PTFE filament yarn, and the second warp yarn is Ne: 38 / 2 yarn fineness containing 93% Spun yarn of Nomex meta-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber; weft direction: the first weft yarn is 600 denier PTFE filament yarn, the second weft yarn is Ne: 38 / 2. Spun yarns of 93% Nomex meta-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber of yarn fineness; the interweaving arrangement is 2:2 along the weft direction.

[0048] In the anti-ice fabric of this embodiment, fabric warp density: 33 / cm, weft den...

Embodiment 2

[0051] Embodiment 2 anti-icing fabric containing polytetrafluoroethylene

[0052] The ice-resistant fabric provided in this embodiment includes PTFE short fibers and aramid fibers, wherein the fabric is made of PTFE filaments and aramid fibers in a plain weave pattern at a weight ratio of 1:2 and is interwoven in warp and weft.

[0053] Specifically, in the warp direction: the first warp yarn is 500 denier PTFE staple fibers, and every third warp yarn is PTFE staple fibers in the warp direction, and the second warp yarn is Ne: 40 / 2 yarn fineness containing 93% Nomex Spun yarn of para-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber; weft direction: 1st weft is 600 denier PTFE staple fiber, 2nd weft is Ne: 40 / 2 yarn Fineness spun yarns containing 93% Nomex meta-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber, interweaving along the weft direction in a ratio of 2:2.

[0054] In the ice-resistant fabric of this embodiment, the fabric warp densi...

Embodiment 3

[0057] Embodiment 3 anti-icing fabric containing polytetrafluoroethylene

[0058] The ice-resistant fabric provided in this embodiment includes PTFE filaments and aramid fibers, wherein the fabric is formed by interweaving warp and weft in a plain weave pattern with PTFE filaments and aramid fibers at a weight ratio of 1:5.

[0059] Specifically, warp direction: the first warp yarn is 300 denier PTFE filament yarn, every third warp yarn is PTFE filament yarn, and the second warp yarn is Ne: 60 / 2 yarn fineness containing 93% Spun yarn of Nomex meta-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber; weft direction: the first weft yarn is 300 denier PTFE filament yarn, the second weft yarn is Ne: 60 / 2 The spun yarn of yarn fineness comprising 93% Nomex meta-aramid fiber, 5% Kevlar para-aramid fiber and 2% conductive fiber, interweaving along the weft direction at a ratio of 2:2.

[0060] In the anti-ice fabric of this embodiment, fabric warp density: 40 / cm, weft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com