Tantalum surface carbonization modification method and product prepared through tantalum surface carbonization modification method

A surface carbonization and modification technology, which is applied in the field of anti-corrosion and anti-corrosion of tantalum surface, can solve the problems of complex process and difficult control of modified layer structure, and achieve the effect of simple preparation process, enhanced surface performance of tantalum, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 The carbide modified layer prepared on the surface of pure tantalum flake metal using an external heating source auxiliary heating method

[0050] The preparation parameters of the carbide modified layer in this example are shown in Table 1 below.

[0051] Table 1 Preparation conditions of the carbide layer on the surface of tantalum

[0052]

[0053] In order to obtain a relatively thick carbide layer on the surface of metal tantalum, in this embodiment, a baking temperature of 200°C and a baking time of 1h are used; the ion beam current intensity is 3000mA, and external heating is used, and the corresponding working temperature is 1500°C , the working time is 1h; plus vacuuming and shutdown time, the total time length in this embodiment reaches 4h.

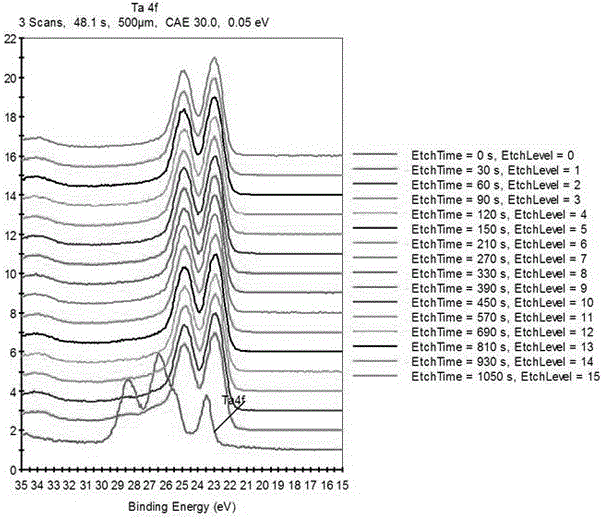

[0054] Obtain a carbide layer on the metal tantalum surface by the preparation parameters in table 1, and carry out X-ray photoelectron spectroscopy (XPS) component analysis to the carbide on the surface, th...

Embodiment 2

[0059] Example 2 Preparation of carbonized modified layer on the surface of cylindrical metal tantalum

[0060] The preparation parameters of the carbide modified layer in this example are shown in Table 2 below.

[0061] Table 2 Preparation conditions of the carbide layer on the surface of tantalum

[0062]

[0063] In order to investigate the ability of carbonization modification on the surface of the cylindrical metal tantalum to be used for modification of the crucible, in this embodiment, the total time length of the process environment is controlled. In order to achieve the above goals, in Example 2, the baking temperature was 200°C, and at the same time, in order to reduce the influence of impurity gases, the baking was extended to 2h; plus vacuuming and shutdown time, the total length of time in this example is 4h .

[0064] The carbide layer was obtained on the surface of the cylindrical metal tantalum workpiece by simply heating the hollow cathode through the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com