Digital PCR chip and method based on surfactant-modified PDMS

A surfactant and chip technology, applied in the fields of medicine, environmental science, and biology, can solve the problems of affecting PCR reaction efficiency and poor sealing effect, and achieve the effects of low cost of consumables, easy observation and statistical analysis, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the design and manufacture of mold

[0035] On the basis of studying the effects of various chip cavity shapes, microchannel sizes, bonding and sampling methods on liquid flow resistance and stability, the present invention finally finds that the microchannel connects the cylindrical cavity, and after the chip is thermally bonded, Using its own vacuum negative pressure sample injection method, the sample can be quickly introduced and automatically separated, and the stability of the sample in the micro reaction chamber is good.

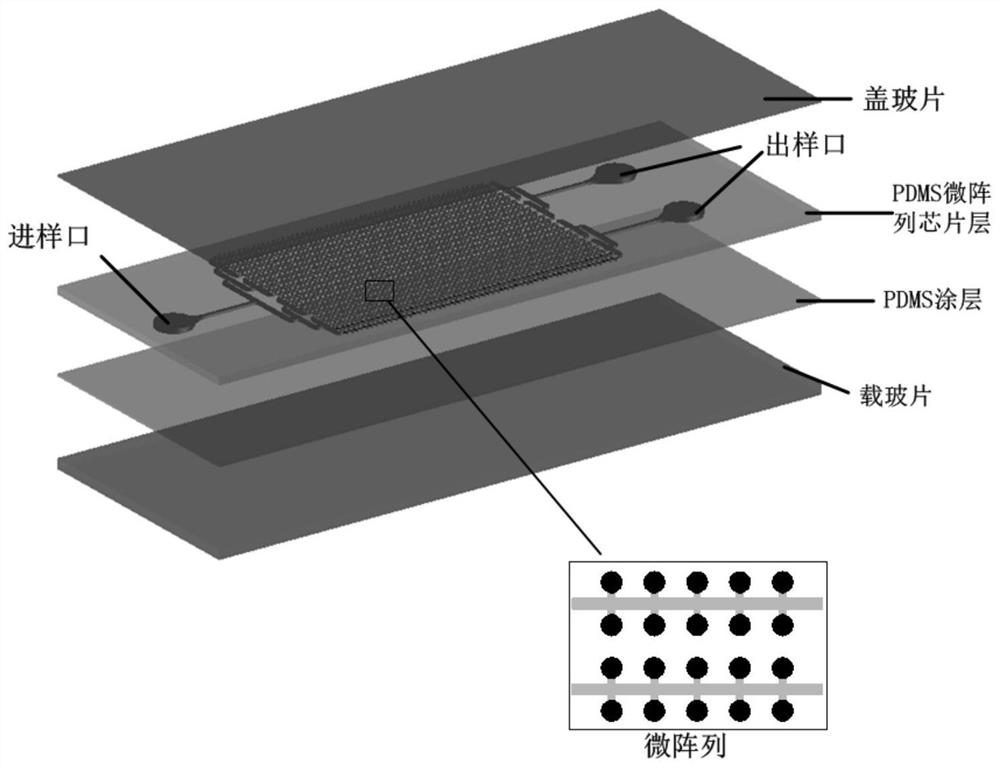

[0036] The chip structure is composed of three parts: the sample inlet area, the array area and the sample outlet area (see figure 1 PDMS microarray chip layer). First, use CAD software to design patterns and print the mask plate, and then use negative photoresist SU8 3050 to fabricate micropipes and microreaction chambers in layers on the silicon wafer. The width of the micro-pipes in the sample inlet area and the sample outlet...

Embodiment 2

[0037] Embodiment 2: the preparation of PDMS chip

[0038] After the silicon wafer mold was fabricated, the PDMS chip was cast by soft etching molding. First mix the PDMS prepolymer and the curing agent at a ratio of 10:1 (mass ratio), stir well, and then add 0.1 to 2.0 g of surfactants (such as tween 20, span 80, Triton100 or betaine per 100 g of the mixture) Surfactants commonly used in biological reactions can be mixed again, stirred evenly, degassed by vacuum, poured on the above mold, and thinly coated with the same mixed liquid PDMS on the glass slide, let stand together for 1h , after curing, peel off the PDMS on the mold, punch holes, stick the pipe surface and the coated glass coating surface together, discharge the air in the veneer, and finally put the bonded PDMS into the 85°C Heat on a hot plate for 10 min to fully bond. In the present invention, the surfactant is directly doped into the PDMS monomer, and the surfactant gathers on the surface of the PDMS after c...

Embodiment 3

[0039] Example 3: Automatic sampling of liquid samples and generation of microdroplet arrays

[0040] PCR premix: Here, the PCR reaction solution is compatible with the conventional PCR reaction solution. The PCR reaction system is: 20 μL of the premix solution contains 10ul Roche 480Probe Premix, 250nM EGFR gene exon 21 upstream and downstream primers, 200nMTaqMan probe, 10 ng of genomic DNA.

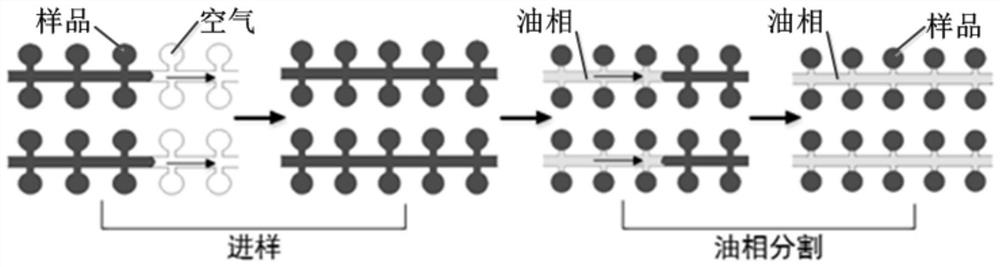

[0041] First, prepare the PCR premix, that is, the sample, inject the sample into the chip inlet after vacuuming and degassing, and use the negative pressure of the PDMS chip after vacuuming to suck the sample, and the sample gradually fills the microchannel and the holes on both sides along the microchannel. cavity (see figure 2 : sample injection process), after all the reaction chambers are filled with samples, inject the pre-mixed oil phase into the injection port, and paste a small piece of degassed PDMS blank block on the sample port of the chip to guide the introduction of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com