Heat radiation paint for LED (light emitting diode) lamp

A technology of LED lamps and heat-dissipating coatings, applied in the field of coatings, can solve the problems of product weather resistance and water resistance that cannot meet the requirements, affect the service life of LED coatings, and poor performance such as anti-corrosion, acid and alkali resistance, etc., to shorten the curing time, Effect of increasing crosslink density and curing rate, improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

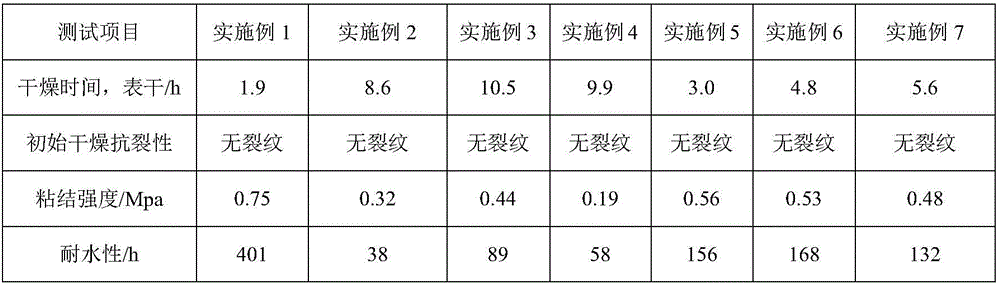

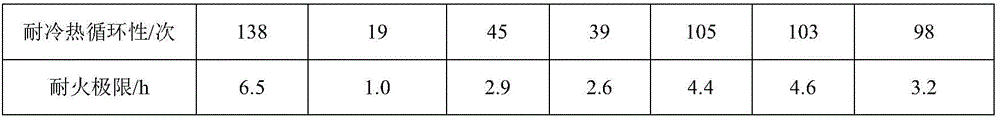

Examples

Embodiment 1

[0025] With 8 parts by weight of drift sand, 11 parts by weight of polytetrafluoroethylene particles, 7 parts by weight of nano-titanium dioxide, 7 parts by weight of purple sand, 8 parts by weight of silicon nitride, 3 parts by weight of KH-560, 2 parts by weight of Parts of KH-550, 8 parts by weight of epoxy-terminated polyetheramine, 9 parts by weight of β-cyclodextrin modified amino-terminated sulfonated polybenzimidazole, 5 parts by weight of 1,4,5,8 -naphthalene tetracarboxylic anhydride, 3 parts by weight of 8-naphthylamine-1-sulfonic acid, 4 parts by weight of 1,5-naphthalene disulfonic acid, 8 parts by weight of dodecyl mercaptan, 30 parts by weight of ethanol and Add 70 parts by weight of deionized water into the gravity-free mixer, open the flying knife to avoid adhesion and prevent uneven stirring, and the stirring time is 10 minutes before discharging.

[0026] The epoxy-terminated polyetheramine is prepared by the following method:

[0027] In a 1000mL dry three...

Embodiment 2

[0032] With 8 parts by weight of drift sand, 11 parts by weight of polytetrafluoroethylene particles, 7 parts by weight of nano-titanium dioxide, 7 parts by weight of purple sand, 8 parts by weight of silicon nitride, 3 parts by weight of KH-560, 2 parts by weight of Parts of KH-550, 8 parts by weight of epoxy-terminated polyetheramine, 9 parts by weight of amino-terminated sulfonated polybenzimidazole, 5 parts by weight of 1,4,5,8-naphthalene tetracarboxylic anhydride, 3 parts by weight The 8-naphthylamine-1-sulfonic acid of parts by weight, the 1,5-naphthalene disulfonic acid of 4 parts by weight, the dodecyl mercaptan of 8 parts by weight, the ethanol of 30 parts by weight and the deionized water of 70 parts by weight Add it to a gravity-free mixer, turn on the flying knife to avoid adhesion and prevent uneven mixing, and the stirring time is 10 minutes before discharging.

[0033] The epoxy-terminated polyetheramine is prepared by the following method:

[0034] In a 1000m...

Embodiment 3

[0038]With 8 parts by weight of drift sand, 11 parts by weight of polytetrafluoroethylene particles, 7 parts by weight of nano-titanium dioxide, 7 parts by weight of purple sand, 8 parts by weight of silicon nitride, 3 parts by weight of KH-560, 2 parts by weight of Parts of KH-550, 9 parts by weight of β-cyclodextrin modified amino-terminated sulfonated polybenzimidazole, 5 parts by weight of 1,4,5,8-naphthalene tetracarboxylic anhydride, 3 parts by weight of 8- Add naphthylamine-1-sulfonic acid, 4 parts by weight of 1,5-naphthalene disulfonic acid, 8 parts by weight of dodecyl mercaptan, 30 parts by weight of ethanol and 70 parts by weight of deionized water into a gravity-free mixer , open the flying knife to avoid adhesion and prevent uneven stirring. The stirring time is 10 minutes, and the material is discharged.

[0039] The β-cyclodextrin modified amino-terminated sulfonated polybenzimidazole is prepared by the following method:

[0040] 0.11 moles of 3,3'-diaminobenz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com