Modified polyphenyl ether resin and application thereof

A polyphenylene ether resin and modification technology, which is applied in the field of copper clad laminates, can solve the problems of the significance of undescribed hydrocarbon groups, the influence of electrical properties, heat resistance, and the uniformity of the resin matrix, and achieve phase separation "islands in the sea" "Phenomenon improvement, improved adhesion, and heat-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1~7 and comparative preparation example 1

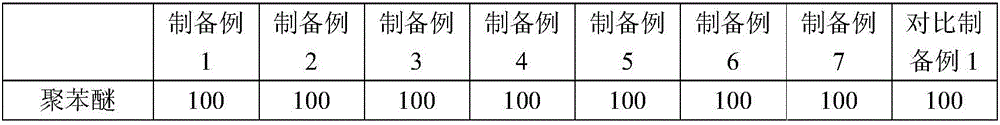

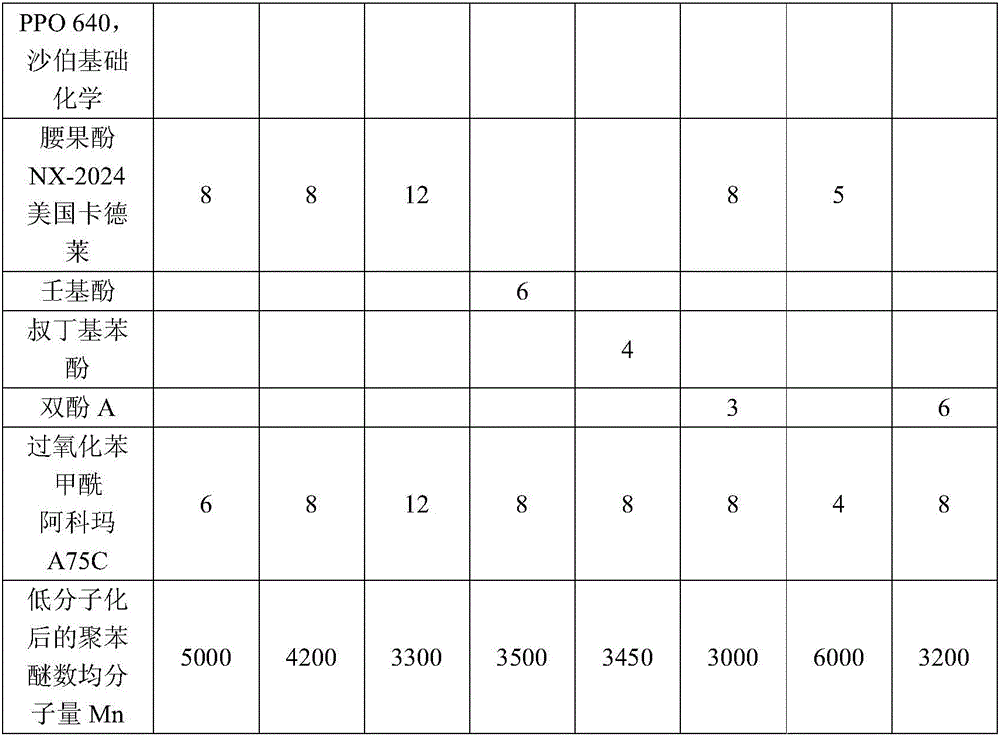

[0053] Add 100 parts of polyphenylene ether powder, 200 parts of toluene and a specific number of phenolic compounds (see Table 1 for the type and number of parts) into a reactor equipped with a stirring, heating and reflux device, stir and heat to 95 ° C, keep warm Stir to dissolve completely. Divide a specific number of peroxides into ten parts, put them into the reaction kettle one by one, keep warm for 8 hours, and obtain the toluene solution of the polyphenylene ether resin modified with low molecular weight. Concentrate the above toluene solution in a rotary evaporator, then add it dropwise in methanol, filter to obtain a precipitate, and dry the precipitate in a blast oven at 100°C to obtain a low-molecular-weight modified polyphenylene ether resin. Using toluene as the mobile phase, the number average molecular weight (Mn) of the resin was measured, and the results are shown in Table 1.

[0054] Table 1

[0055]

[0056]

Embodiment 1~9 and comparative example 1~3

[0058] The modified polyphenylene ether, epoxy resin and cyanate resin obtained in the preparation example are fully dissolved in toluene (Dicy is fully dissolved in DMF), and then mixed with accelerators such as 2 ethyl-4 methylimidazole and zinc isooctanoate (See Table 2 for the type and number of parts) Mix evenly to obtain a toluene solution of the polyphenylene ether resin composition.

[0059] Impregnate the NE glass fiber cloth (Nittobo Co., Ltd., NEA2116) with the resin composition, and dry it at 155°C for 2-10 minutes to remove the solvent, so that the volatile content is less than 1%, and the gel time of the resin is 150s-200s , to obtain a prepreg with a resin content of about 55%.

[0060] Cover one HOz inverted copper foil on each side of the four overlapping prepregs, and hot press at a temperature of 200 °C and a pressure of 3.0 MPa for 90 minutes to obtain a double-sided copper-clad laminate.

[0061] Table 2

[0062]

[0063]

[0064]

Embodiment 10~14 and comparative example 4~6

[0066] Fully dissolve the modified polyphenylene ether, epoxy resin, and cyanate resin obtained in the preparation example in toluene, then mix them evenly with accelerators such as 2 ethyl-4 methylimidazole and zinc isooctanoate, and then add fillers and barriers. Combustion agent (see Table 3 for the type and number of parts), and uniformly dispersed by means such as stirring and high-speed shearing, to obtain a toluene solution of the polyphenylene ether resin composition.

[0067] Impregnate NE glass fiber cloth (Nittobo Co., Ltd., NEA2116) with the resin composition, and dry it at 155°C for 2-10 minutes to remove the solvent, so that the volatile content is less than 1%, and the gel time of the resin is 150s-200s , to obtain a prepreg with a resin content of about 55%.

[0068] Cover one HOz inverted copper foil on each side of the four overlapping prepregs, and hot press at a temperature of 200 °C and a pressure of 3.0 MPa for 90 minutes to obtain a double-sided copper-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com