Preparation method and application of high-solid-content water-based polyurethane resin and coating thereof

A technology of water-based polyurethane and high solid content, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of no mention of high-solid content water-based polyurethane emulsion synthesis, difficulty in preparing high-solid content water-based polyurethane emulsion, and no specific disclosure of coatings Preparation technology and other issues, to achieve obvious environmental protection value, freeze-thaw resistance advantages, good fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

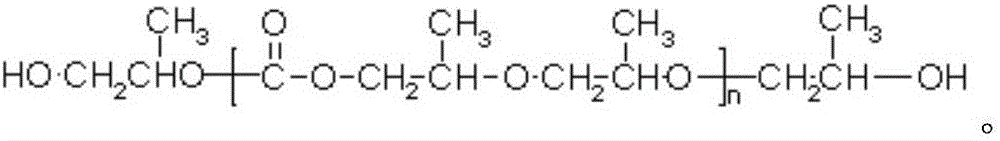

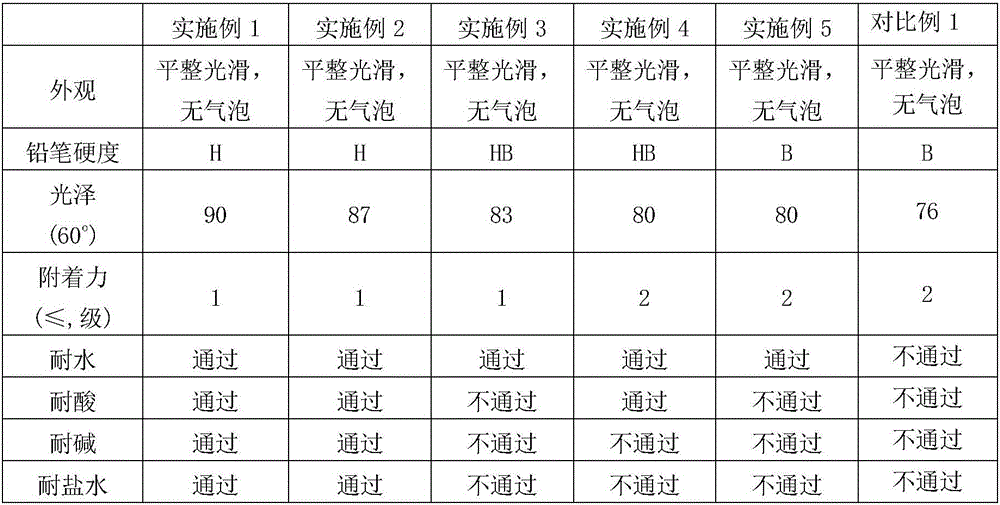

[0039]React 70g of polypropylene carbonate diol with a molecular weight of 2500 and 35g of isophorone diisocyanate at 90°C for 2 hours, add 7g of 1,4-butanediol, 1g of trimethylolpropane, and 70g of acetone, and add 0.02g of dibutyltin dilaurate, react at 60°C for 8 hours, cool down to 45°C, stir for 10 minutes, add 0.5g of A95, react for 30 minutes, add 40g of acetone, quickly add 160g of deionized water for high-speed emulsification, stir for 10 minutes Minutes; put the obtained product on a rotary evaporator, vacuum decompresses, removes solvent, and obtains a high solid content aqueous polyurethane emulsion based on polypropylene carbonate polyol.

[0040] 150g of the water-based polyurethane emulsion based on polypropylene carbonate polyol prepared above, 0.05g of leveling agent TEGO 410, 0.07g of thickener WT-105A, 1g of water-based color paste, 0.8g of ethylene glycol monobutyl ether, Add 0.02g of defoamer TEGOFoamex 825 and the rest of deionized water into the tank in ...

Embodiment 2

[0042] React 45g of polypropylene carbonate diol with a molecular weight of 2000 and 20g of toluene diisocyanate at 80°C for 2.5 hours, add 7g of 1,6-hexanediol, 1g of trimethylolpropane, 80g of acetone, and add 0.02g of dilaurel Acetate dibutyltin, react at 60°C for 5 hours, cool down to 45°C, stir for 10 minutes, add 0.6g APS, after reacting for 60 minutes, add 40g of acetone, quickly add 100g of deionized water for high-speed emulsification, and stir for 10 minutes; the obtained product On a rotary evaporator, the solvent was removed under vacuum to obtain a high solid content aqueous polyurethane emulsion based on polypropylene carbonate polyol.

[0043] 150g of the above-mentioned prepared polypropylene carbonate polyol-based aqueous polyurethane emulsion, 0.1g leveling agent BYK346, 0.05g thickener ACRYSOL TM Add RM 12W, 1g water-based color paste, 1g ethylene glycol monobutyl ether, 0.02g defoamer TEGFOamex 825 and the rest of deionized water into the tank in sequence, ...

Embodiment 3

[0045] 40g of polypropylene carbonate diol with a molecular weight of 2000 and 20g of polybutylene adipate diol with a molecular weight of 3000 were reacted with 35g of isophorone diisocyanate at 90°C for 2.5 hours, and 6g of diol was added Diethylene glycol, 1.5g trimethylolpropane, 90g acetone, add 0.02g dibutyltin dilaurate, react at 60°C for 5 hours, cool down to 45°C, stir for 10 minutes, add 0.5gA95, react for 30 minutes Afterwards, add 40g of acetone, quickly add 80g of deionized water for high-speed emulsification, and stir for 10 minutes; put the resulting product on a rotary evaporator, vacuum and decompress, and remove the solvent to obtain a high-solid-content aqueous solution based on polypropylene carbonate polyols. polyurethane emulsion.

[0046] The aqueous polyurethane emulsion based on polypropylene carbonate polyol of 150g above-mentioned preparation, 0.05g leveling agent 8030, 0.07g Thickener ACRYSOL TM RM 5000, 1g water-based color paste, 0.8g ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com