Flow casting process based method for preparing substrate of circulator

A casting process and circulator technology, which is applied in the substrate preparation of YIG ferrite materials and in the field of electronic materials, can solve the problems of high microwave magnetic loss, low density, and high porosity of thick films, and achieve narrow ferromagnetic resonance line width, Excellent temperature stability and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Main ingredient formula: Y 3-x Ca x sn x Fe 5-x o 12 , x=0.06;

[0027] 2) Primary ball milling: Using a planetary ball mill, using zirconium balls, milling for 4 to 8 hours under the condition of 241r / min;

[0028] 3. Pre-burning: Pre-burning at 1000°C~1200°C, keep warm for 1~3 hours;

[0029] 4. Doping: Add the following additives: 0.2wt% Bi 2 o 3 , 0.10wt% BaTiO 3 ;

[0030] 5. Secondary ball milling: use a planetary ball mill, add 40~50wt% organic binder and 40~50wt% absolute ethanol to the powder on the original basis, use zirconium balls, under the condition of 241r / min, ball mill 4~8 hours;

[0031] 6. Tape casting: the slurry obtained in the above steps is cast to obtain a raw film tape with a thickness of 100-120 μm;

[0032] 7. Lamination: According to the thickness requirement, the raw film belt lamination is 8~15 layers, and it is pressed and formed under 6MPa;

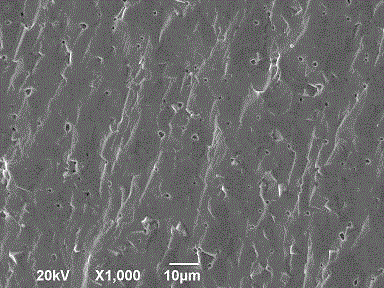

[0033] 8. Sintering: heat preservation at 1400°C for 4 hours in air atmosphere. ...

Embodiment 2

[0036] 1) Main ingredient formula: Y 3-x Ca x sn x Fe 5-x o 12 , x=0.09;

[0037] 2) Primary ball milling: Using a planetary ball mill, using zirconium balls, milling for 4 to 8 hours under the condition of 241r / min;

[0038] 3. Pre-burning: Pre-burning at 1000°C~1200°C, keep warm for 1~3 hours;

[0039] 4. Doping: Add the following additives: 0.2wt% Bi 2 o 3 , 0.10wt% BaTiO 3 ;

[0040] 5. Secondary ball milling: use a planetary ball mill, add 40~50wt% organic binder and 40~50wt% absolute ethanol to the powder on the original basis, use zirconium balls, under the condition of 241r / min, ball mill 4~8 hours;

[0041] 6. Tape casting: the slurry obtained in the above steps is cast to obtain a raw film tape with a thickness of 100-120 μm;

[0042] 7. Lamination: According to the thickness requirement, the raw film belt lamination is 8~15 layers, and it is pressed and formed under 6MPa;

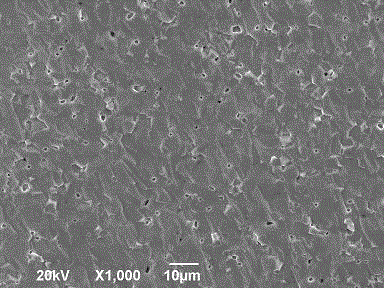

[0043] 8. Sintering: heat preservation at 1400°C for 4 hours in air atmosphere. ...

Embodiment 3

[0045] 1. Main ingredient formula: Y 3-x Ca x sn x Fe 5-x o 12 , x=0.06;

[0046] 2. One-time ball milling: use a planetary ball mill, use zirconium balls, and mill for 4 to 8 hours under the condition of 241r / min;

[0047] 3. Pre-burning: pre-burning at 1000°C~1200°C, keep warm for 1~3 hours;

[0048] 4. Doping: Add the following additives: 0.2wt% Bi 2 o 3 , 0.10wt% BaTiO 3 ;

[0049] 5. Secondary ball milling: use a planetary ball mill, add 40~50wt% organic binder and 40~50wt% absolute ethanol to the powder on the original basis, use zirconium balls, under the condition of 241r / min, ball mill 4~8 hours;

[0050] 6. Tape casting: the slurry obtained in the above steps is cast to obtain a raw film tape with a thickness of 100-120 μm;

[0051] 7. Lamination: According to the thickness requirement, the raw film belt lamination is 8~15 layers, and it is pressed and formed under 6MPa;

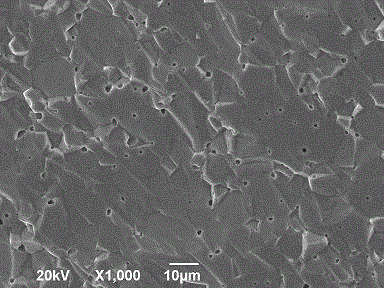

[0052]8. Sintering: heat preservation at 1420°C for 4 hours in air atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com