Actuator based on magneto-rheological fluid

A magnetorheological fluid and driver technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of insufficient driving accuracy, difficult driving accuracy, and large influence, avoiding mutual interference, Suitable for a wide temperature range and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

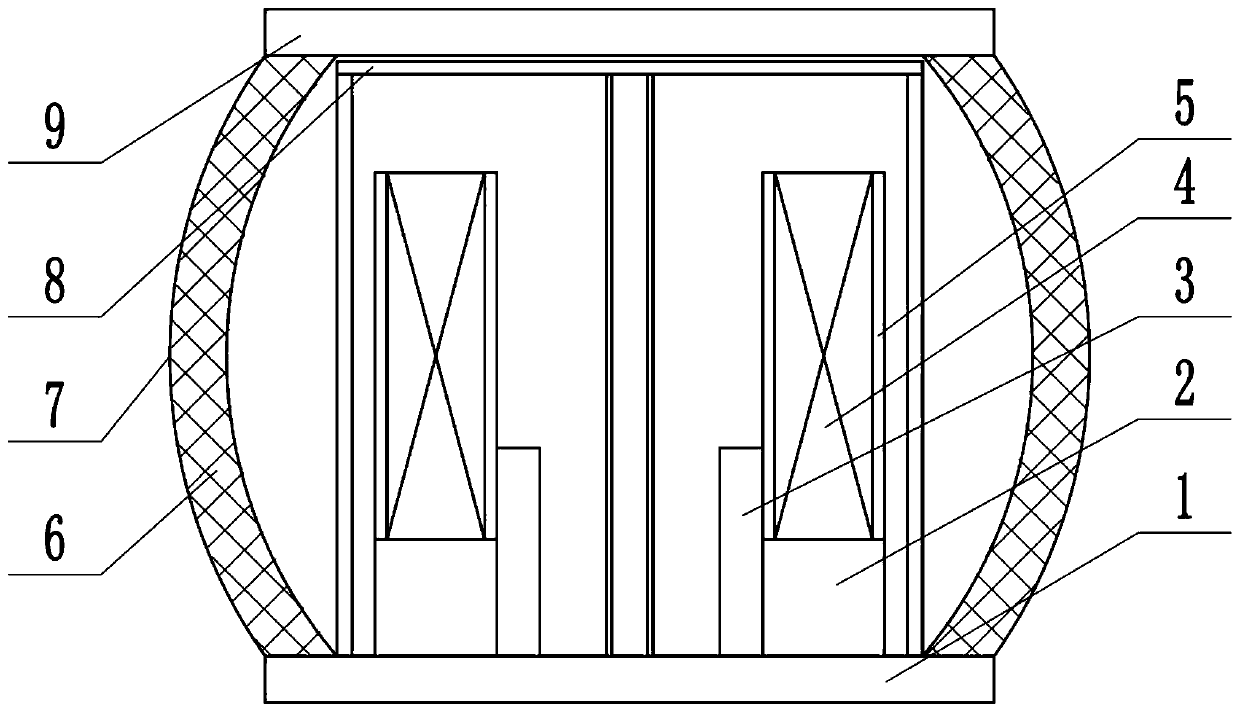

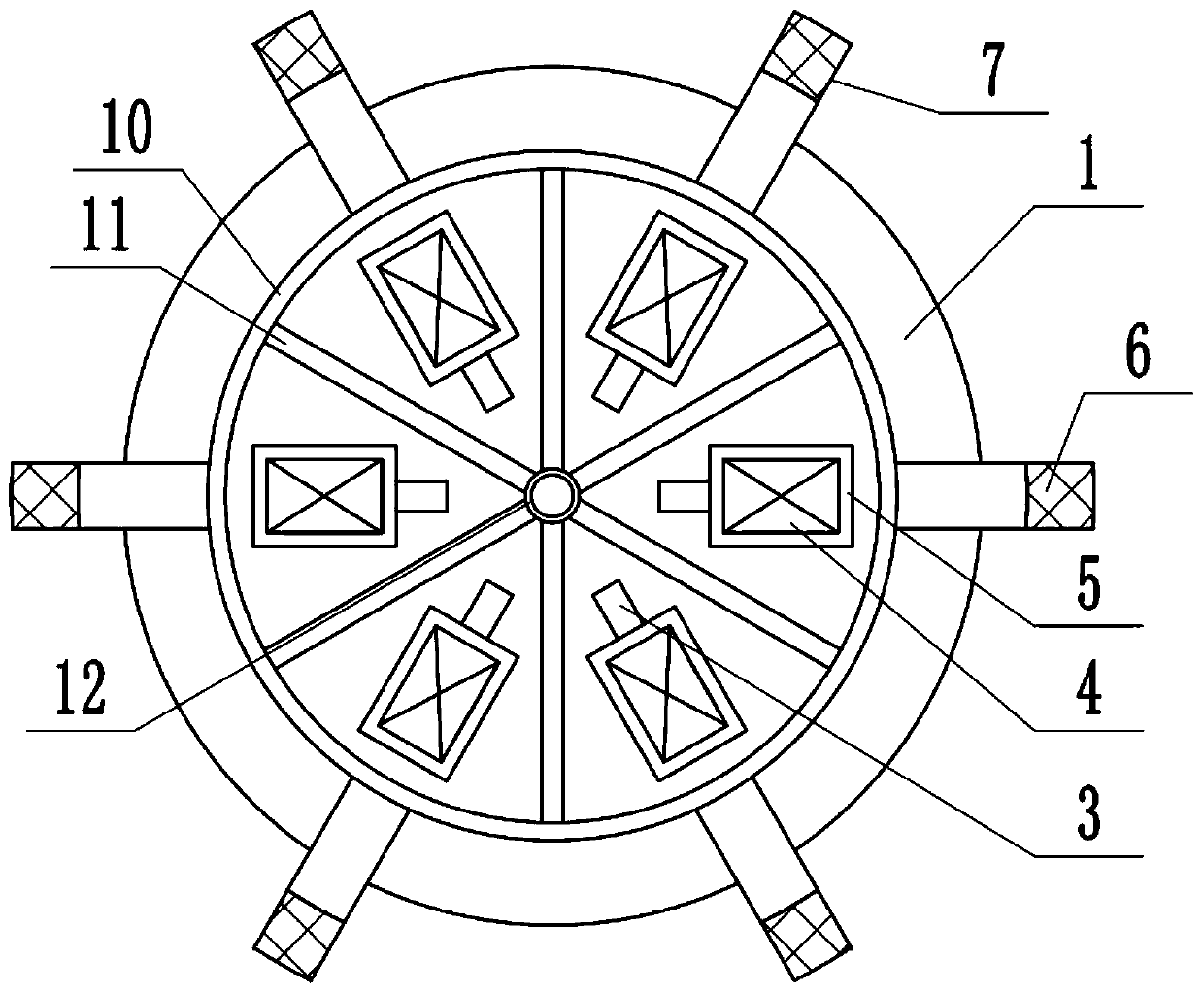

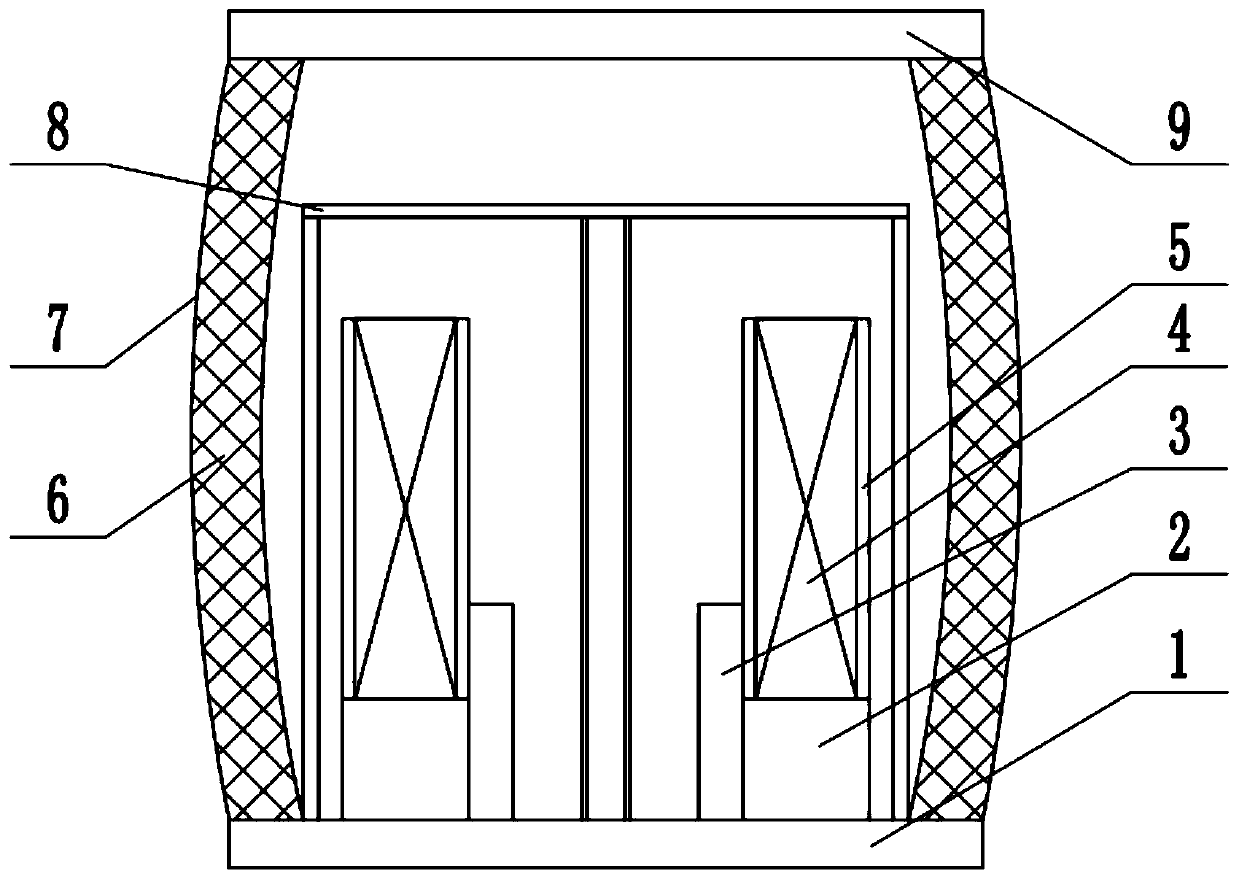

[0035] In a typical implementation of the present application, such as Figure 1-4 As shown, a magneto-rheological fluid-based actuator is proposed.

[0036] It mainly includes a static platform 1, a dynamic platform 9 and a driving part. The static platform is fixed to the external frame, and the moving platform is connected to the actuator as an output end. The distance between the static platform and the moving platform is changed by the driving part so that the moving platform Output displacement to achieve the purpose of driving the actuator.

[0037] There is a minimum distance between the static platform and the dynamic platform when the driving part is in a free state, and a sleeve 10 is arranged between this distance, one end of the sleeve is installed on the static platform, and the other end is connected with a disc 8, and the dynamic platform Contacting this disc, the disc supports the moving platform in the free state of the driving part, keeping the minimum dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com