Preparation method of compact chromium oxide product with high thermal shock resistance

A chromium oxide and stability technology, applied in the field of refractory materials, can solve the problems of inability to meet alkali-free glass fiber kilns, reduce production efficiency and overall service life, and poor bulk density gradients, so as to eliminate impurities such as chromium and carbon compounds. Generate, improve sintering performance and service performance, and solve the effect of large gradient difference between internal and external bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

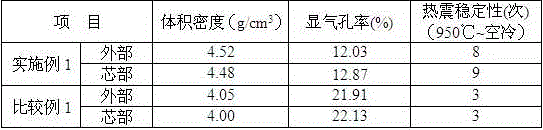

[0020] Example 1: Selecting 325 mesh chromium oxide composite micropowder: Cr 2 O 3 Micro powder 86.0wt.%, TiO 2 Micropowder 4.0wt.%, metal zirconium powder 10.0wt.%, uniformly mixed with calcium lignosulfonate 1.0wt.% and polyvinyl alcohol 0.1Wt.% to make a slurry, centrifugal granulation, and press it into an electric furnace after 180MPa press In the kiln, 99.99% Ar gas is introduced into the kiln through the control of a flow meter to ensure a slight positive pressure of 10mm water column in the kiln to prevent outside air from entering the kiln, and then heat preservation at 1650°C for 2 hours to obtain high thermal shock stability. Sexually dense chromium oxide products. Comparative Example 1 is that a sample of the same specification prepared without metal zirconium powder is sintered at 1700°C for 2 hours in an air atmosphere. The comparison of the volume density, apparent porosity and thermal shock stability of their inner and outer regions is shown in Table 1.

[0021]...

Embodiment 2

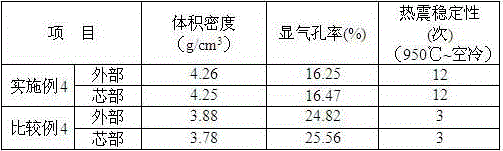

[0023] Example 2: Selecting 325 mesh chromium oxide composite micropowder: Cr 2 O 3 Micropowder 93.0wt.%, TiO 2 Micropowder 4.0wt.%, metal zirconium powder 3.0wt.%, uniformly mixed with polyvinyl alcohol 1.0wt.%, slurry spray granulation, after 150MPa isostatic pressure molding, into the electric furnace kiln, controlled by the flow meter 99.999% Ar gas is introduced into the kiln. Observation ensures that there is a slight positive pressure of 10mm water column in the kiln to prevent outside air from entering the kiln. Then the high thermal shock stability compact chromium oxide product is sintered at 1450℃ for 8 hours. Comparative Example 2 is that a sample of the same specification prepared without metal zirconium powder is sintered at 1700°C for 8 hours in an air atmosphere. The comparison of the volume density, apparent porosity and thermal shock stability of their inner and outer regions is shown in Table 2.

[0024] Table 2

[0025]

Embodiment 3

[0026] Example 3: Selecting 325 mesh chromium oxide composite micropowder: Cr 2 O 3 Micropowder 95.0wt.%, TiO 2 Micropowder 4.0wt.%, metal zirconium powder 1.0wt.%, uniformly mixed with carboxymethyl cellulose powder 0.1wt.% and polyvinyl alcohol 0.1Wt.% to make a slurry, centrifuge and granulate, then press and form with a 150MPa machine before filling In the electric furnace kiln, 99.999% Ar gas is introduced into the kiln through the control of a flow meter. Observe to ensure that the kiln has a 10mm water column with a slight positive pressure to prevent outside air from entering the kiln. The high heat is then sintered at 1550℃ for 4 hours. Shock stable compact chromium oxide products. In Comparative Example 3, a sample of the same specification prepared without metal zirconium powder was sintered at 1700°C for 4 hours in an air atmosphere. The comparison of the volume density, apparent porosity and thermal shock stability of their inner and outer regions is shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com