A kind of refractory material for liquid line furnace wall and liquid outlet nozzle of non-ferrous smelting melting furnace and its preparation method

A technology of refractory material and liquid outlet, which is applied in the field of refractory materials, can solve the problems of increasing the viscosity of slag, reducing the high temperature performance of refractory materials, destroying the structure of refractory materials, etc., so as to reduce decomposition reaction, ensure thermal shock stability, avoid Density and slag resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

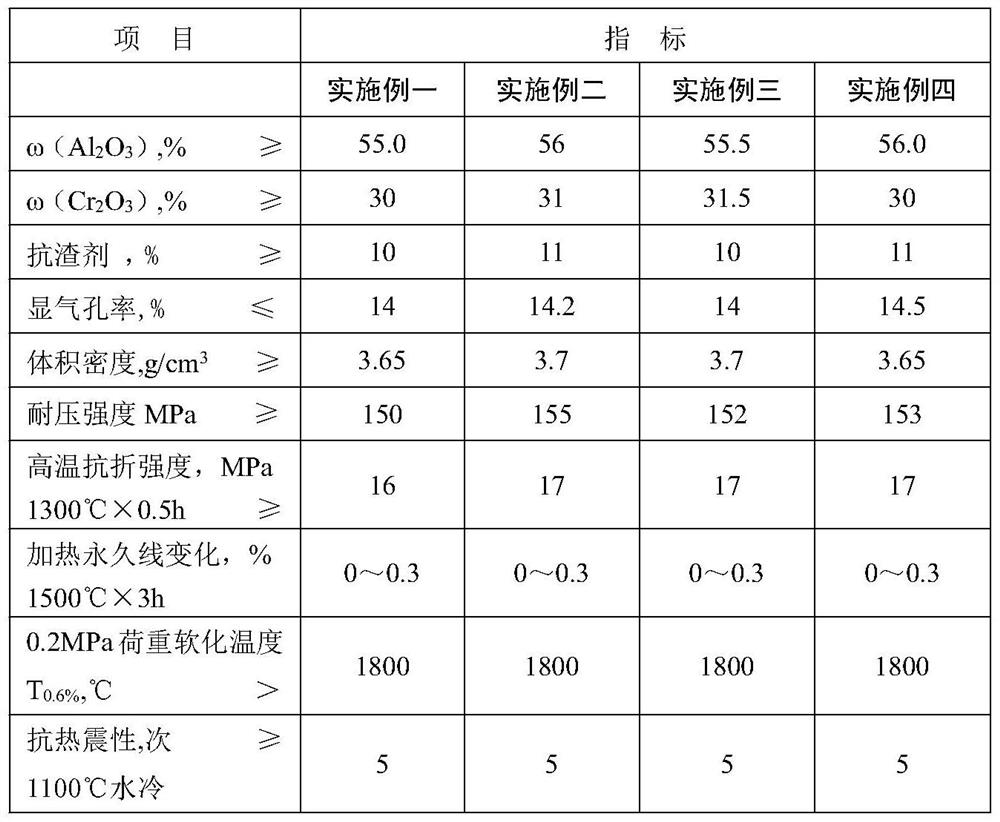

Examples

Embodiment 1

[0030] Composition of 50 parts of Al-Cr eutectic, 20 parts of Fe-Cr spinel, 4 parts of Magnesium-Chromium spinel and 30 parts of Fe-Al spinel according to particle size, according to the principle of first coarse and then fine, first dry in wet mill Mix, after the granules and fine powder are mixed evenly, add 3 parts of gel binder mixed with α-alumina micro-powder and aluminum dihydrogen phosphate solution with a mass ratio of 3:7, press with a pressure of 1000T, and shape it into bricks. Put it in a desiccator and dry it at 140°C for 24 hours, then put the dried bricks in a high-temperature tunnel kiln for firing at a firing temperature of 1600°C, and hold for 8 hours at the firing temperature .

Embodiment 2

[0032] 60 parts of aluminum-chromium eutectic, 10 parts of iron-chromium spinel, 7 parts of magnesium-chromium spinel and 20 parts of iron-aluminum spinel are composed according to the particle size. According to the principle of first coarse and then fine, first dry in the wet mill After mixing the granules and fine powder evenly, add 6 parts of α-alumina micro-powder with a mass ratio of 4:5 and aluminum dihydrogen phosphate solution to form a gel binder, press with a pressure of 1200T, and shape it into bricks. Place in a desiccator and dry for 24 hours at a temperature of 140°C, then place the dried bricks in a high-temperature tunnel kiln for firing at a firing temperature of 1550°C, and hold for 7 hours at the firing temperature .

Embodiment 3

[0034] 54 parts of aluminum-chromium eutectic, 16 parts of iron-chromium spinel, 5 parts of magnesium-chromium spinel and 26 parts of iron-aluminum spinel are composed according to particle size. Mix, after the granules and fine powder are mixed evenly, add 4 parts of gel binder mixed with α-alumina micro-powder and aluminum dihydrogen phosphate solution with a mass ratio of 5:7, press with a pressure of 1100T, and shape it into bricks. Place in a desiccator and dry at 100°C for 24 hours, then place the dried bricks in a high-temperature tunnel kiln for firing at a firing temperature of 1600°C, and hold for 6 hours at the firing temperature .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com