Laterite underglaze porcelain and its preparation method

A technology of underglaze color and red clay, which is applied to clay products, other household utensils, household utensils, etc., and can solve the problems of difficulty in forming the middle layer of glaze, poor hand feeling, and low market price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the laterite underglaze color craft porcelain comprises the following steps:

[0033] (1) weigh the ingredients according to the raw material formula of laterite body and make-up soil, crush respectively, pass through a 200-mesh sieve, and wet ball mill to obtain base slurry and make-up soil slurry;

[0034] (2) Mix the Dehua low-temperature stone, Dehua limestone, Dehua quartz, borax and boric acid in the glaze formula evenly, put it into the melting furnace, and melt it into a frit at 1230-1270°C. After the frit is quenched, it is mixed with Dehua high territory wet ball milling to prepare glaze slurry;

[0035] (3) making the base slurry obtained in step (1) into a ceramic body;

[0036] (4) After the ceramic green body is dried, apply a layer of make-up soil slurry on its surface, send it into a kiln, and burn it at 880-920°C for 4-5 hours to obtain a ceramic green body;

[0037] (5) Carry out plain painting decoration on the surface of t...

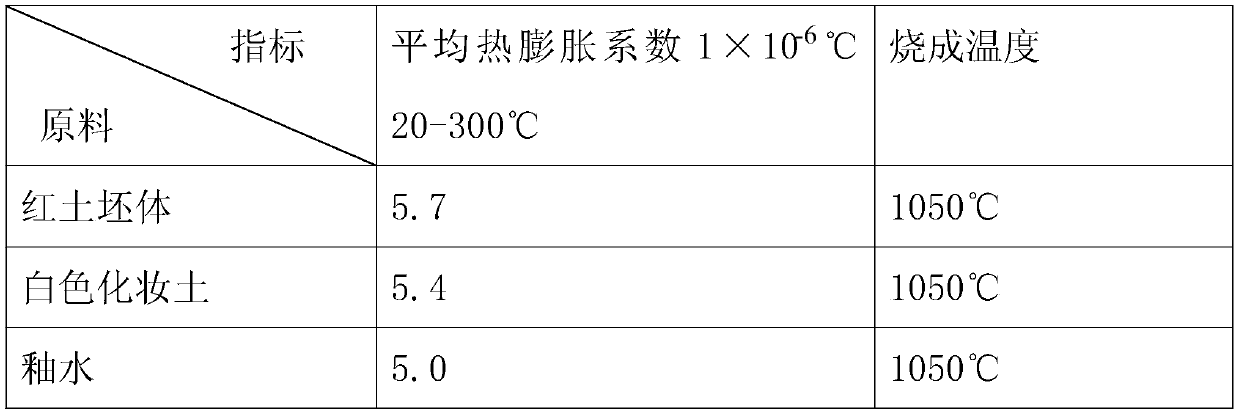

Embodiment 1

[0046] Laterite underglaze craft porcelain, including laterite body, make-up clay and glaze;

[0047] The laterite body includes the following raw materials in parts by weight: 75 parts of Dehua Sanban laterite, 10 parts of dolomite, 20 parts of Dehua quartz, 10 parts of sepiolite, and 10 parts of wollastonite;

[0048] And the chemical composition of the laterite body is as follows: SiO 2 : 63.5%, Al 2 o 3 : 14.6%, Fe 2o 3 : 3.8%, K 2 O: 1.9%, Na 2 O: 0.2%, MgO: 3.2%, CaO: 4.9%, TiO 2 : 0.3%, I.L: 7.6%;

[0049] The make-up soil includes the following raw materials in parts by weight: 32 parts of Dehua clay, 35 parts of Dehua low-temperature stone, 10 parts of dolomite, and 20 parts of Dehua quartz.

[0050] And the chemical composition of makeup soil is as follows: SiO 2 : 66.2%, Al 2 o 3 : 13.7%, K 2 O: 4.1%, Na 2 O: 1.4%, MgO: 2.6%, CaO: 4.9%, Fe 2 o 3 : 0.4%, I.L: 6.7%.

[0051] The glaze includes the following raw materials in parts by weight: 22 parts of...

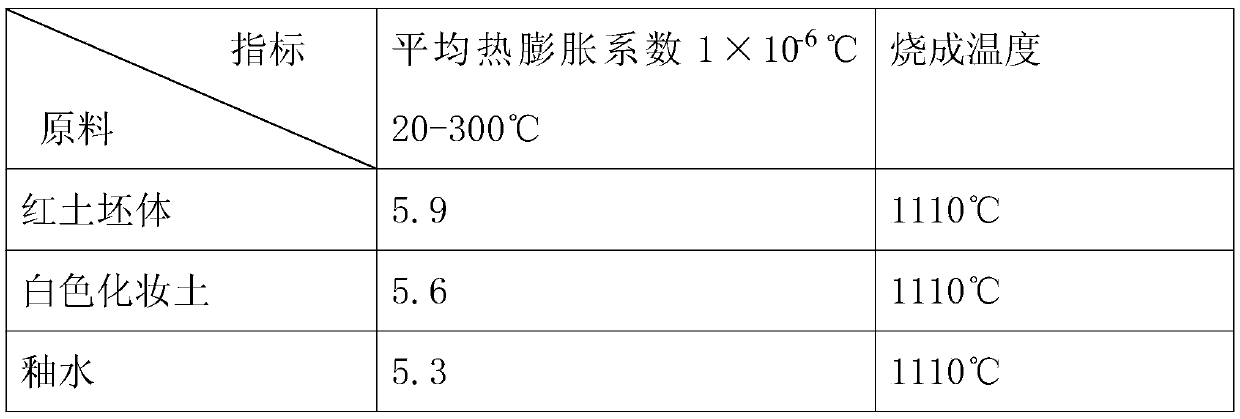

Embodiment 2

[0070] Laterite underglaze craft porcelain, including laterite body, make-up clay and glaze;

[0071] The laterite body includes the following raw materials in parts by weight: 65 parts of Dehua Sanban laterite, 15 parts of dolomite, 15 parts of Dehua quartz, 12 parts of sepiolite, and 8 parts of wollastonite;

[0072] And the chemical composition of the laterite body is as follows: SiO 2 : 57.8%, Al 2 o 3 : 17.8%, Fe 2 o 3 : 3.2%, K 2 O: 2.3%, Na 2 O: 0.4%, MgO: 2.6%, CaO: 6.1%, TiO 2 : 0.5%, I.L: 9.3%;

[0073] The make-up soil includes the following raw materials in parts by weight: 28 parts of Dehua clay, 45 parts of Dehua low-temperature stone, 15 parts of dolomite, and 15 parts of Dehua quartz.

[0074] And the chemical composition of makeup soil is as follows: SiO 2 : 59.4%, Al 2 o 3 : 16.7%, K 2 O: 5.1%, Na 2 O: 1.2%, MgO: 3.2%, CaO: 6.1%, Fe 2 o 3 : 0.2%, I.L: 8.1%.

[0075] The glaze includes the following raw materials in parts by weight: 28 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com