Preparation method for normal-temperature rapid repairing material for municipal roads and bridges and construction step of preparation method

A technology for repairing materials and construction steps is applied in the field of preparation of rapid repairing materials at room temperature for municipal roads and bridges. The effect of large water volume and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

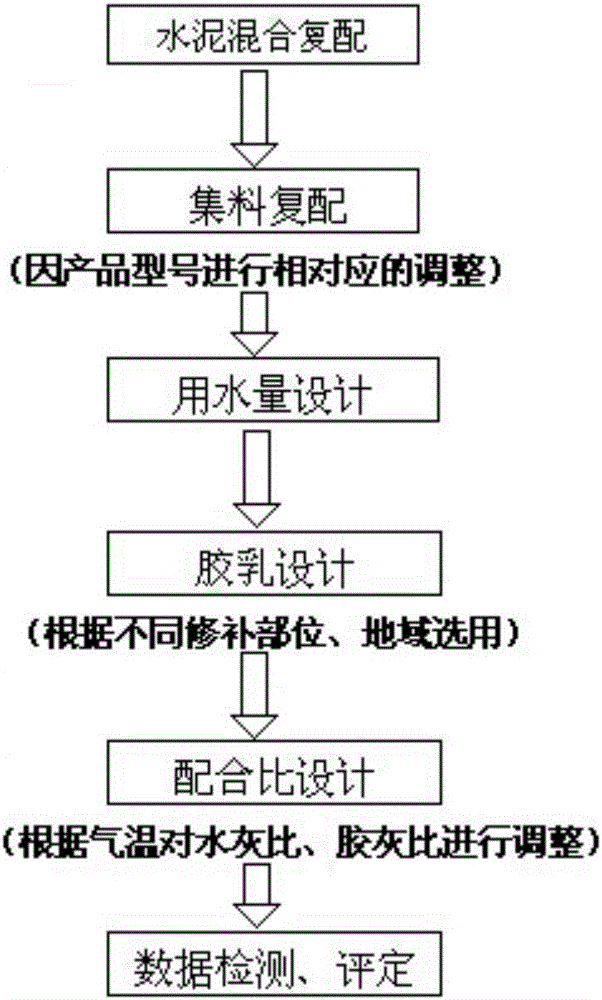

[0043] Such as figure 1 Shown, a kind of preparation method of normal temperature fast repair material for municipal road and bridge comprises the following steps:

[0044](1) Choose 42.5 ordinary Portland cement, special cement, mixed aggregate (select the corresponding gradation according to the thickness of the part used), cement polymer emulsion, retarder (determine the amount according to the transportation distance or construction time) , water, artificial or mechanical stirring at room temperature can quickly form strength, and can be closely combined with the old concrete structure to form a whole, with good crack resistance and freeze-thaw resistance;

[0045] The special cement is one of high-grade portland cement or special cement; the special cement is composed of the following components in parts by weight: 15 parts of powder anti-stripping agent, 15 parts of mineral powder, 10 parts of polymer rubber powder part and 50 parts of sulphoaluminate cement;

[0046] ...

specific Embodiment 2

[0057] Such as figure 1 Shown, a kind of preparation method of normal temperature fast repair material for municipal road and bridge comprises the following steps:

[0058] (1) Choose 42.5 ordinary Portland cement, special cement, mixed aggregate (select the corresponding gradation according to the thickness of the part used), cement polymer emulsion, retarder (determine the amount according to the transportation distance or construction time) , water, artificial or mechanical stirring at room temperature can quickly form strength, and can be closely combined with the old concrete structure to form a whole, with good crack resistance and freeze-thaw resistance;

[0059] The special cement is one of high-grade portland cement or special cement; the special cement is composed of the following components in parts by weight: 20 parts of powder anti-stripping agent, 20 parts of mineral powder, 20 parts of polymer rubber powder part and 70 parts of sulphoaluminate cement;

[0060]...

specific Embodiment 3

[0071] Such as figure 1 Shown, a kind of preparation method of normal temperature fast repair material for municipal road and bridge comprises the following steps:

[0072] (1) Choose 42.5 ordinary Portland cement, special cement, mixed aggregate (select the corresponding gradation according to the thickness of the part used), cement polymer emulsion, retarder (determine the amount according to the transportation distance or construction time) , water, artificial or mechanical stirring at room temperature can quickly form strength, and can be closely combined with the old concrete structure to form a whole, with good crack resistance and freeze-thaw resistance;

[0073] The special cement is one of high-grade Portland cement or special cement; the special cement is composed of the following components in parts by weight: 17 parts of powder anti-stripping agent, 18 parts of mineral powder, 14 parts of polymer rubber powder part and 63 parts of sulphoaluminate cement;

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com