A kind of lead-free glass powder based on graphene modification and its preparation method and electronic paste

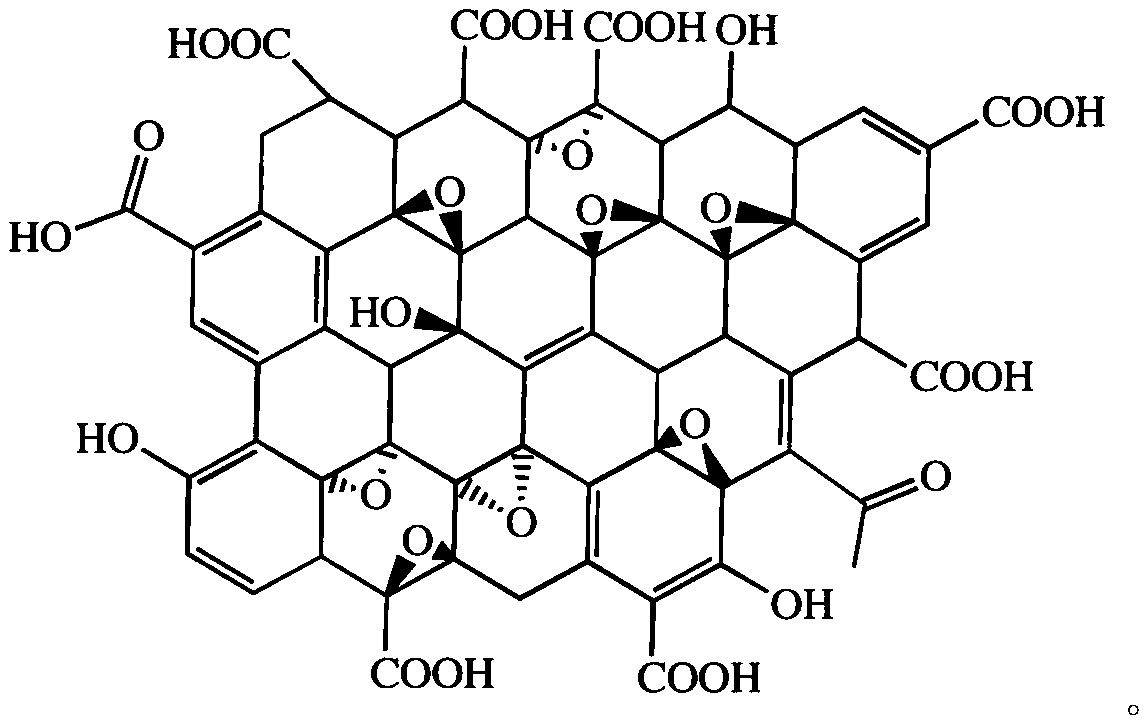

A graphene and glass powder technology, applied in the field of crystalline silicon solar cell conductive paste, can solve problems such as lead toxicity and environmental protection, and achieve the effects of improving current convergence and exporting effects, mild conditions, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

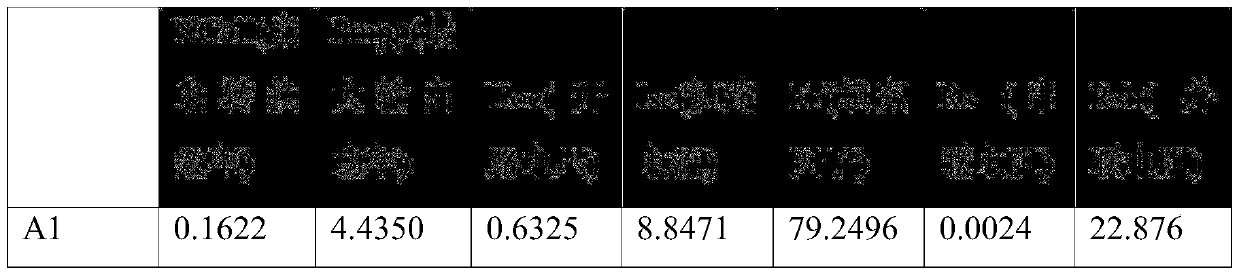

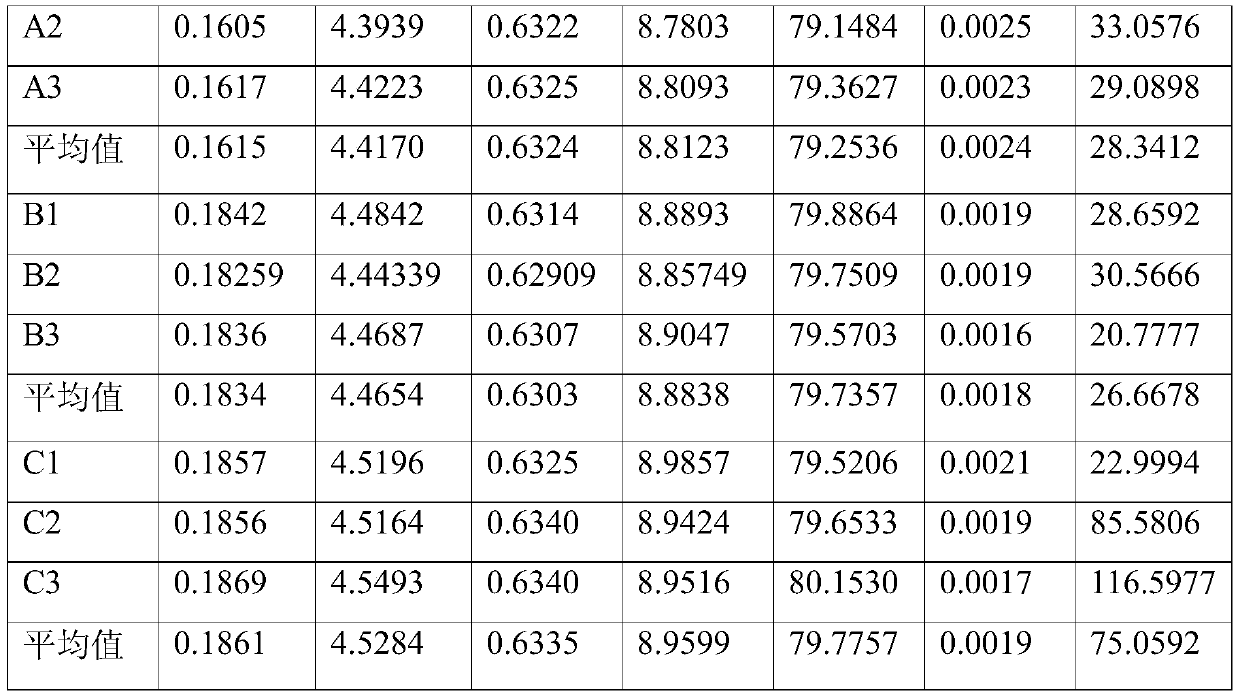

Examples

preparation example Construction

[0030] First provide the preparation method of the highly dispersed lead-free glass powder modified by graphene of the present invention, specifically comprise the following steps:

[0031] Step 1, preparation of lead-free glass powder:

[0032] (1) First accurately weigh each oxide with an analytical balance, and its composition and weight percentage are: 30-55% Bi 2 o 3 , 10~35%TeO 2 , 5-15% ZnO, 3-5% MgO, 5-15% SiO 2 , 2~4%P 2 o 5 , 5 ~ 15% B 2 o 3 , 1~12%Al 2 o 3 , further preferably including oxide V with a weight percentage content of 0-5% 2 o 5 , CaO, SnO 2 At least one of the oxides, the total percentage content of each oxide is 100%;

[0033] (2) Prepare the required glass powder by melting and quenching, mix the above-mentioned oxides evenly and place them in an aluminum crucible, and then place the aluminum crucible in a high-temperature electric furnace at a set temperature (about 1200°C) for 10- After 50 minutes, take it out and quench it in distilled...

Embodiment 1

[0056] A preparation method of lead-free glass powder, comprising:

[0057] Take the following substances by weight percentage: 30% Bi 2 o 3 , 35% TeO 2 , 15% ZnO, 3% MgO, 5% SiO 2 , 2%P 2 o 5 , 5% B 2 o 3 , 5% Al 2 o 3 , then mix the above weighed oxides evenly and place them in an aluminum crucible, then place the aluminum crucible in a high-temperature electric furnace at about 1200 ° C for 10 minutes, take it out and quench it in distilled water to room temperature to obtain coarse glass powder, then A jet mill was used to pulverize the coarse glass powder to a particle size of 3-5 μm, and the lead-free glass powder sample was obtained after washing and drying.

Embodiment 2

[0059] A preparation method of lead-free glass powder, comprising:

[0060] Weigh the following substances by weight percentage: 55% Bi 2 o 3 , 10% TeO 2 , 5% ZnO, 3% MgO, 5% SiO 2 , 2%P 2 o 5 , 10% B 2 o 3 , 10% Al 2 o 3 , then mix the above weighed oxides evenly and place them in an aluminum crucible, then place the aluminum crucible in a high-temperature electric furnace at about 1200°C for 50 minutes of melting, then take it out and quench it in distilled water to room temperature to obtain coarse glass powder, then A jet mill is used to pulverize the coarse glass powder to a particle size of 3-5 μm, and the lead-free glass powder sample is obtained after washing and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com