A kind of synthesis method of strong acid agar-based chromatography medium with high adsorption capacity

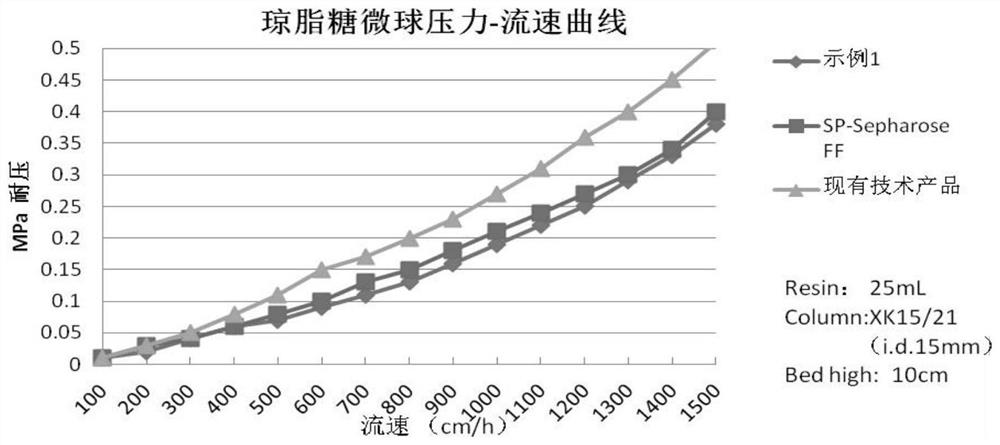

A synthesis method and high adsorption technology, applied in chemical instruments and methods, ion exchange, microcapsule preparations, etc., can solve the problems of slow flow rate, uneven distribution of active groups and ligands, limited pressure, etc., and achieve the degree of functionalization. High, save the preparation cost, simplify the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a) Water phase preparation

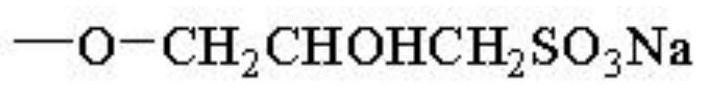

[0036] Prepare a 4% agarose aqueous solution (containing 10% KCl), heat to 92° C., the agarose is completely dissolved, add 3-chloro-2-hydroxypropanesulfonate solid and stir until dissolved to obtain an aqueous phase. The mass ratio of the sodium 3-chloro-2-hydroxypropanesulfonate to agarose is 2:1.

[0037] b) Suspension preparation

[0038] The water phase was poured into the toluene oil phase at 70°C, and the volume ratio of the oil phase to the water phase was 8:1 to obtain a suspension; the polyvinyl acetate and oleic acid contained in the toluene had a mass of 2% of the mass of toluene, respectively. % and 0.8%;

[0039] c) Strong acid functionalization and crosslinking reaction

[0040] Add epichlorohydrin to the suspension in step b), and dropwise add a NaOH solution with a mass concentration of 50%, and drop it within 1 hour; keep the temperature at 70° C., and react for 3 hours to obtain a cross-linked reaction product; The mas...

Embodiment 2

[0046] a) Water phase preparation

[0047] Prepare agarose aqueous solution (containing 10% KCl) with a mass concentration of 4%, heat to 95° C., the agarose is completely dissolved, add 3-chloro-2-hydroxypropanesulfonate solid and stir until dissolved to obtain an aqueous phase. The mass ratio of the sodium 3-chloro-2-hydroxypropanesulfonate to agarose is 2.5:1.

[0048] b) Suspension preparation

[0049] Pour the water phase into the toluene oil phase at 70°C, and the volume ratio of the oil phase to the water phase is 7:1 to obtain a suspension; the polyvinyl acetate and oleic acid contained in the toluene have a mass of 100% of the mass of toluene, respectively. 1.5% and 1%;

[0050] c) Strong acid functionalization and crosslinking reaction

[0051] Add epichlorohydrin to the suspension in step b), and dropwise add NaOH solution with a mass concentration of 50%, and dropwise addition is completed within 1 hour; keep the temperature at 70° C., and react for 4 hours to o...

Embodiment 3

[0057] a) Water phase preparation

[0058] Prepare an aqueous solution of agarose (containing 10% KCl) with a mass concentration of 4%, heat it to 93° C., dissolve all the agarose, add 3-chloro-2-hydroxypropanesulfonate solid and stir until dissolved to obtain an aqueous phase; The mass ratio of sodium 3-chloro-2-hydroxypropanesulfonate to agarose is 1.5:1.

[0059] b) Suspension preparation

[0060] Pour the water phase into the toluene oil phase at 70°C, and the volume ratio of the oil phase to the water phase is 6-8:1 to obtain a suspension; the polyvinyl acetate and oleic acid contained in the toluene have a mass of toluene 1.8% and 1.2% of mass;

[0061] c) Strong acid functionalization and crosslinking reaction

[0062] Add epichlorohydrin to the suspension in step b), and dropwise add NaOH solution with a mass concentration of 50%, and dropwise addition is completed within 1 hour; keep the temperature at 70° C., and react for 6 hours to obtain a cross-linked reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com