A method for producing high-quality iron oxide red pigment from laterite nickel ore acid leaching solution

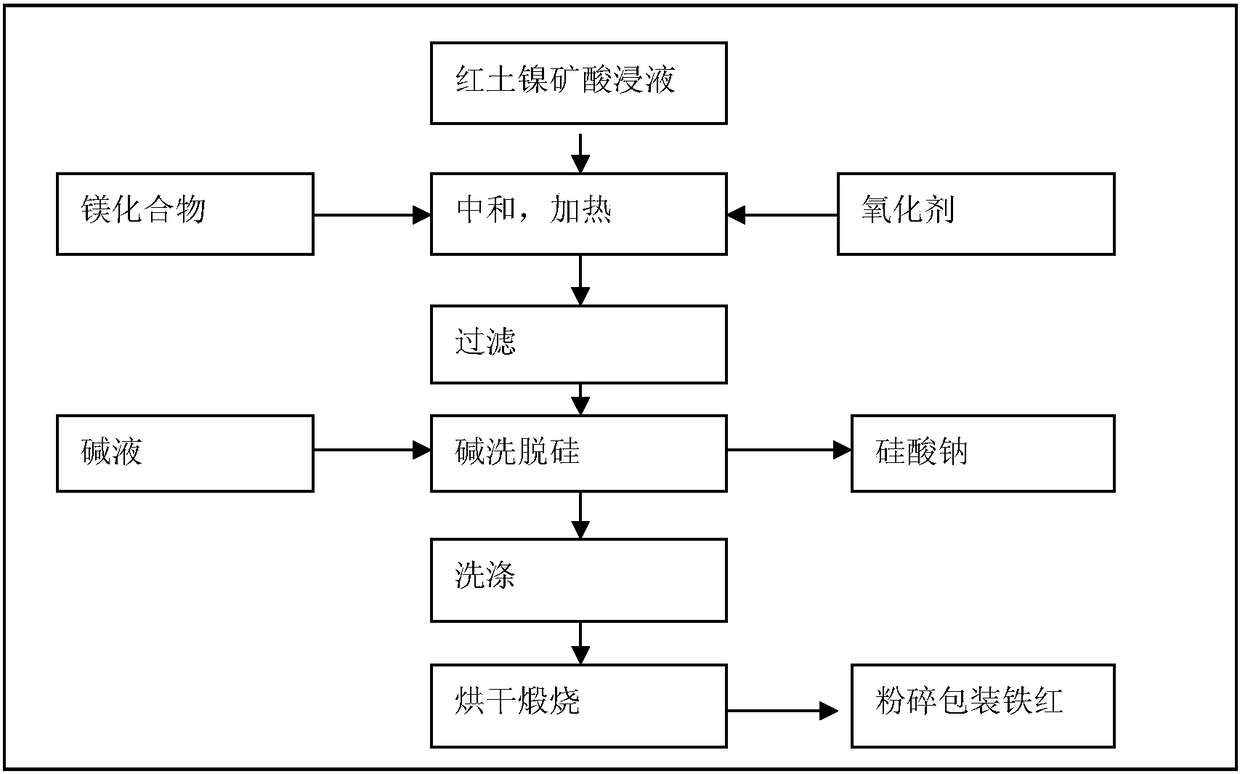

A technology of iron oxide red and laterite nickel ore is applied in the field of resources and environment, which can solve the problems of enterprise burden, long process and high cost, and achieve the effects of reducing neutralization cost, improving hue and improving crystal shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for producing high-quality iron oxide red pigment with laterite nickel ore acid leaching solution, the steps are as follows:

[0026] 1) In the reactor, 1000Kg laterite nickel ore acid leaching solution, its pH=2, Fe 2 0 3 The content is 4.1wt%, heated to 60°C by feeding steam, adding 10kg of magnesium oxide neutralizer to adjust the pH=3, putting in iron oxide seeds, keeping the temperature of the reactor at 65°C, passing through air oxidant for 100 minutes to oxidize to iron oxide Stop oxidation after the color of the pigment reaches the standard;

[0027] 2) The oxidized pickling liquid enters the filter press for filtration, and the liquid enters other processes for processing. The solid is iron oxide red filter cake, and the filter cake is beaten and washed with water once;

[0028] 3) Add 15 kg of 10 wt% sodium hydroxide solution to the washed filter cake to elute the silicon with alkali at 90° C., the silicon forms sodium silicate liquid and discharge ...

Embodiment 2

[0032] A method for producing high-quality iron oxide red pigment with laterite nickel ore acid leaching solution, the steps are as follows:

[0033] 1) In the reactor, 1000kg laterite nickel ore acid leaching solution, its pH=2.6, Fe 2 0 3 The content is 5.0wt%, heated to 90°C by feeding steam, adding 12kg of magnesium hydroxide neutralizer to adjust pH = 4, putting in iron oxide seeds, keeping the temperature of the reactor at 95°C, and passing through air oxidant for 40 minutes until oxidation Stop oxidation after the color of iron pigment reaches the standard;

[0034] 2) The oxidized pickling liquid enters the filter press for filtration, and the liquid enters other processes for processing. The solid is iron oxide red filter cake, and the filter cake is beaten and washed with water once;

[0035] 3) Add 15kg of 10wt% sodium hydroxide solution to the washed filter cake, elute the silicon with alkali at 80°C, the silicon forms sodium silicate liquid and discharge it, and...

Embodiment 3

[0039] A method for producing high-quality iron oxide red pigment from laterite nickel ore acid leaching solution

[0040] 1) In the reactor, 1000kg laterite nickel ore acid leaching solution, its pH=1.5, Fe 2 0 3 The content is 3.8wt%. Heat it to 80°C with steam, add 18kg of magnesium carbonate neutralizer to adjust the pH=3.5, put in iron oxide red seeds, keep the temperature of the reactor at 85°C, and pass in air oxidant for 60 minutes to oxidize Stop oxidation after the color of iron pigment reaches the standard;

[0041] 2) The oxidized pickling liquid enters the filter press for filtration, and the liquid enters other processes for processing. The solid is iron oxide red filter cake, and the filter cake is beaten and washed with water once;

[0042] 3) add 10 wt% to the washed filter cake into 15 kg of sodium hydroxide solution to elute the silicon with alkali at 85° C., the silicon forms sodium silicate liquid and discharge it, and the filter cake enters the calcinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com