Production method of high-purity non-caking ammonium-free potassium bicarbonate

A technology of potassium bicarbonate and production method, applied in the directions of bicarbonate preparation, alkali metal carbonate, chemical instruments and methods, etc., can solve the problem that high-purity potassium bicarbonate cannot be produced, and the removal technology of unsolved anti-caking agent can be solved. , the product clarity is difficult to meet the requirements and other problems, to achieve the effect of low production cost, good product quality and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

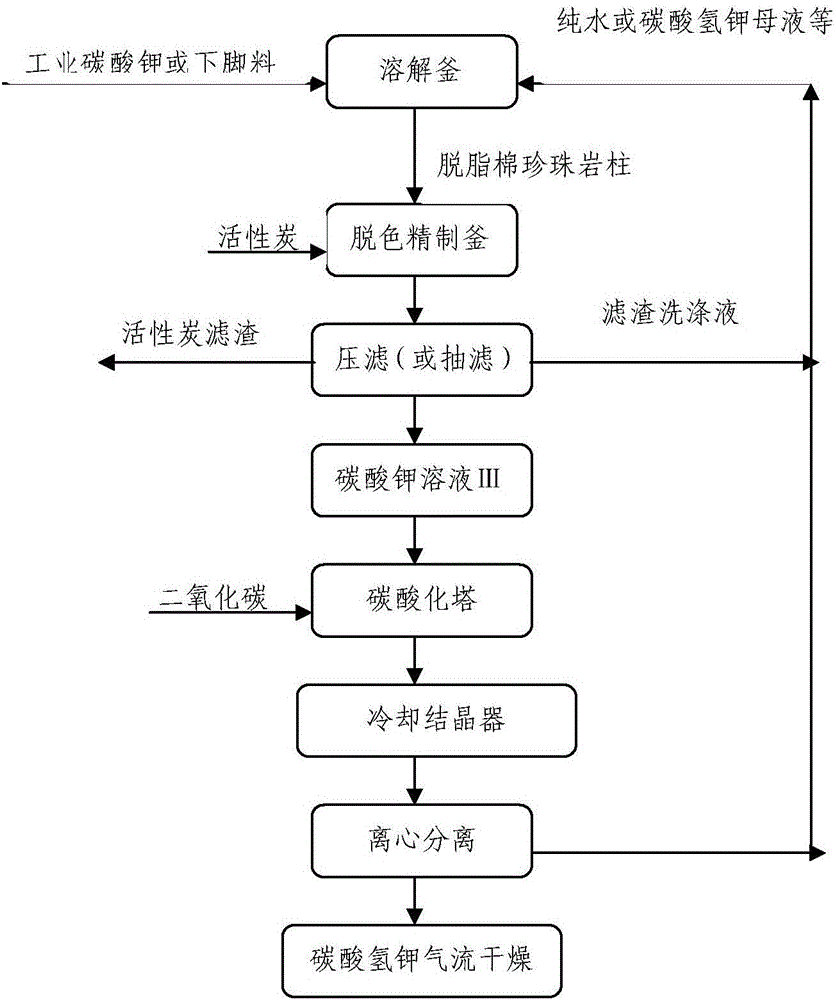

Method used

Image

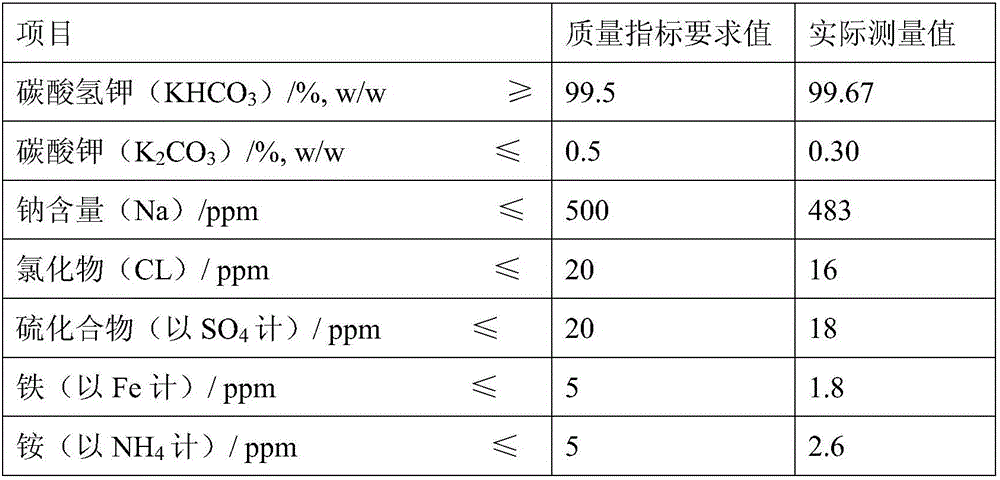

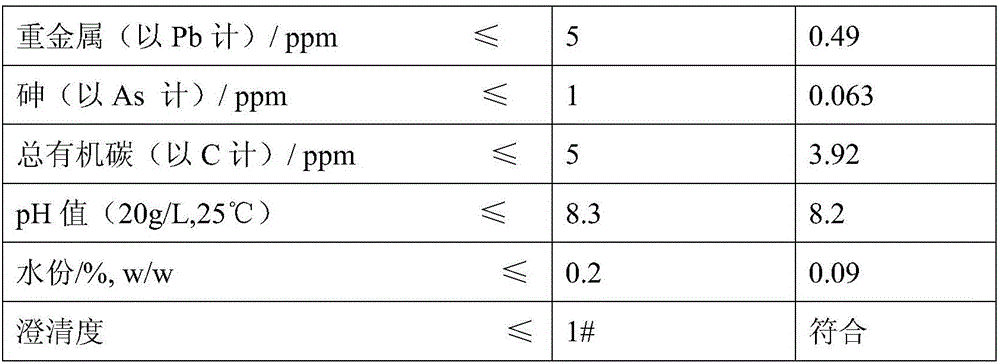

Examples

Embodiment 1

[0057] Embodiment 1, a kind of non-caking non-ammonium high-purity potassium bicarbonate production method, carries out following steps successively:

[0058] 1), put 100 kilograms of industrial potassium carbonate with a mass content of 98% (other indicators all meet the quality standard of GB / T1587-2000 qualified products) into the dissolution tank, add (147 liters) deionized pure water, and heat up to 75°C Dissolve under stirring to obtain 181 liters of potassium carbonate solution I;

[0059] In the potassium carbonate solution I, the potassium carbonate concentration is 550g / L, the sodium ion concentration is 4.8g / L, the chloride ion concentration is 0.5g / L, the sulfate ion concentration is 0.5g / L, the ammonium ion concentration is 6ppm, and the iron ion concentration is 50ppm , the heavy metal concentration is 10ppm, the arsenic concentration is 5ppm, and the temperature is 75°C.

[0060] 2), the potassium carbonate solution I obtained in step 1) is passed through an ad...

Embodiment 2

[0080] Embodiment 2, a kind of non-caking non-ammonium high-purity potassium bicarbonate production method, carry out following steps successively:

[0081] 1), 100 kilograms of content are 98% industrial potassium carbonate (other indicators all meet GB / T1587-2000 qualified product quality standard) drop into dissolving tank, add step 5) potassium bicarbonate mother liquor 150 of gained in the embodiment 1 1, 15 liters of deionized pure water, heated up to 75°C and dissolved under stirring to obtain 218 liters of potassium carbonate solution I;

[0082] In this potassium carbonate solution I, the concentration of potassium carbonate is 450g / L, the concentration of potassium bicarbonate is 200g / L, the concentration of sodium ion is 7.9g / L, the concentration of chloride ion is 0.8g / L, the concentration of sulfate ion is 0.8g / L, and the concentration of ammonium ion is 7ppm, iron ion concentration 83ppm, heavy metal concentration 16ppm, arsenic concentration 8ppm, temperature 75...

Embodiment 3

[0103] Embodiment 3, a kind of non-caking non-ammonium high-purity potassium bicarbonate production method comprises the following steps successively:

[0104] 1), 100 kilograms of mass content are 98% industrial potassium carbonate (other indicators all meet GB / T1587-2000 qualified product quality standard) drop into dissolving tank, add the potassium bicarbonate mother liquor of step 5) gained in embodiment 2 150 liters, 15 liters of deionized pure water, heated to 75°C and dissolved under stirring to obtain 218 liters of potassium carbonate solution I;

[0105] Described potassium carbonate solution I, potassium carbonate concentration is 452g / L, potassium bicarbonate 203g / L, sodium ion concentration 10.5g / L, chloride ion concentration 1.1g / L, sulfate ion concentration 1.1g / L, ammonium ion concentration The concentration is 10ppm, the iron ion concentration is 114ppm, the heavy metal concentration is 22ppm, the arsenic concentration is 11ppm, and the temperature is 75°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com