Method for separating and enriching lithium, aluminum and silicon from fly ash

A technology for fly ash and enrichment of lithium, which is applied in the field of solid waste resource utilization, can solve problems such as unfavorable extraction of lithium, introduction of a large amount of filtrate, and large acid consumption, so as to improve the degree of separation and product quality, and promote the process of alkali leaching. , the effect of improving the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

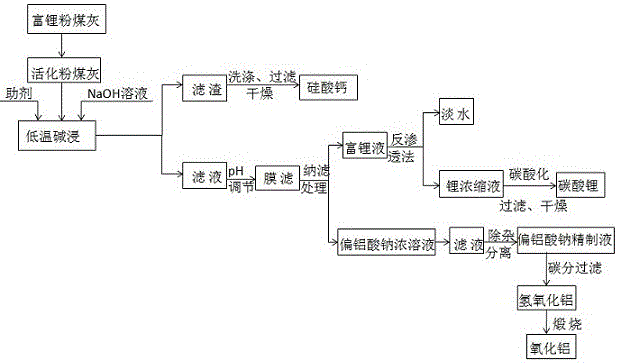

Image

Examples

Embodiment 1

[0041] Put the activated fly ash with a particle size of less than 200 meshes and calcium hydroxide at a mass ratio of 4:1 into the reaction kettle. According to the solid-liquid ratio of the solid mass to 30% sodium hydroxide solution at 1:200, the Stir and boil for 5 hours, filter and separate, the filtrate is used as the raw material for extracting aluminum and lithium, and the filter cake is calcium silicate. The filter cake is washed, filtered, dried, and recovered to obtain calcium silicate products, which can be used as construction and insulation materials.

[0042] Use 2mol / L hydrochloric acid solution and 2mol / l NaOH solution to adjust the pH of the filtrate to 10 under the measurement of the pH meter, and then pump it into the nanofiltration membrane separation system. Due to the retention performance of the membrane, substances with relatively small molecular weights such as water, Lithium hydroxide, etc. are separated from the original filtrate through the membran...

Embodiment 2

[0047] Put the activated fly ash with a particle size of less than 200 mesh and calcium oxide at a mass ratio of 3:1 into the reactor, and stir at 160°C according to the solid-to-liquid ratio of solid mass to 30% sodium hydroxide solution at 1:300 Boil and soak for 4 hours, filter and separate, the filtrate is used as the raw material for extracting aluminum and lithium, and the filter cake is calcium silicate. The filter cake is washed, filtered and dried to recover the finished product of calcium silicate.

[0048] Use 2mol / L hydrochloric acid solution and 2mol / l NaOH solution to adjust the pH of the filtrate to 8.5 under the measurement of the pH meter, and then pump it into the nanofiltration membrane separation system. Due to the retention performance of the membrane, substances with relatively small molecular weights such as water, Lithium hydroxide, etc. are separated from the original filtrate through the membrane to form a lithium-rich solution collected through water...

Embodiment 3

[0053] Put the activated fly ash with a particle size of less than 150 mesh and calcium oxide at a mass ratio of 2:1 into the reactor, and stir at 160°C according to the solid-to-liquid ratio of solid mass to 20% sodium hydroxide solution at 1:300 Boil and soak for 4 hours, filter and separate, the filtrate is used as the raw material for extracting aluminum and lithium, and the filter cake is calcium silicate. The filter cake is washed, filtered and dried to recover the finished product of calcium silicate.

[0054] Use 2mol / L hydrochloric acid solution and 2mol / l NaOH solution to adjust the pH of the filtrate to 9 under the measurement of the pH meter, and then pump it into the nanofiltration membrane separation system. Due to the retention performance of the membrane, substances with relatively small molecular weights such as water, Lithium hydroxide, etc. are separated from the original filtrate through the membrane to form a lithium-rich solution collected through water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com