Magnetic pulse forming-based panel and pipe connection method and device

A magnetic pulse forming and connecting device technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high production cost of large coils, low mold replacement efficiency, etc., and achieve fast and efficient forming process, production efficiency improvement, Small rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

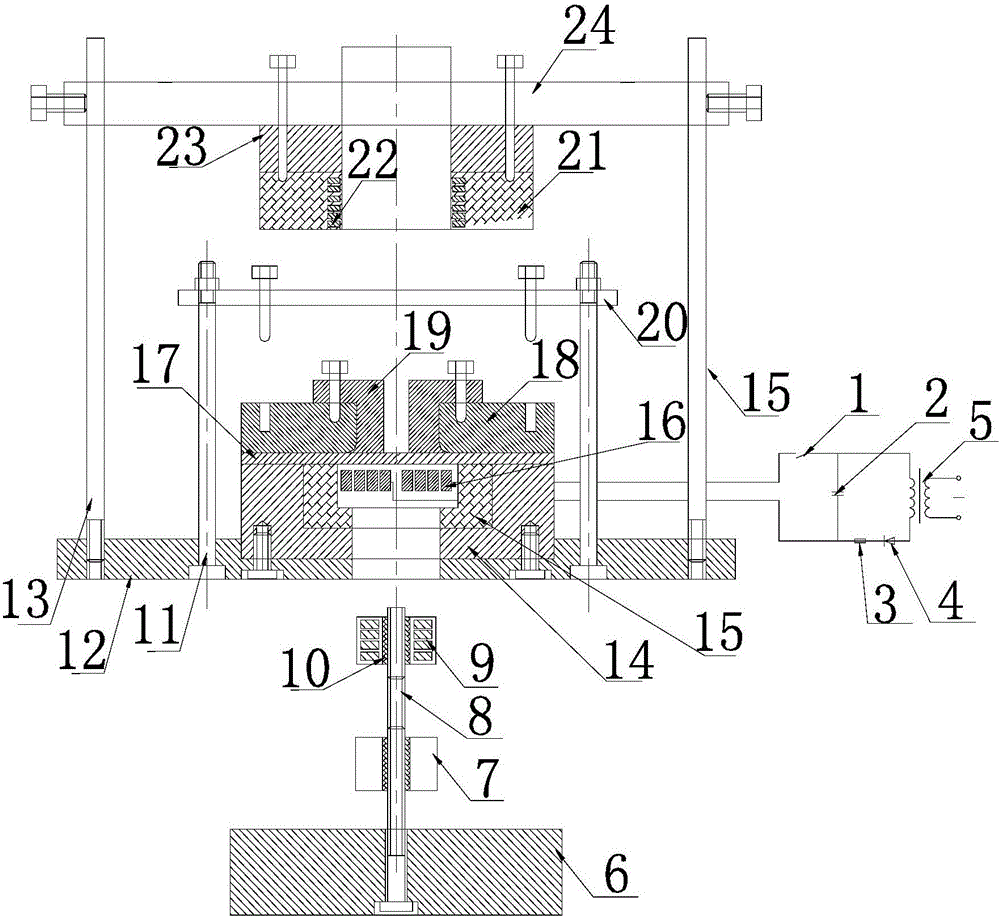

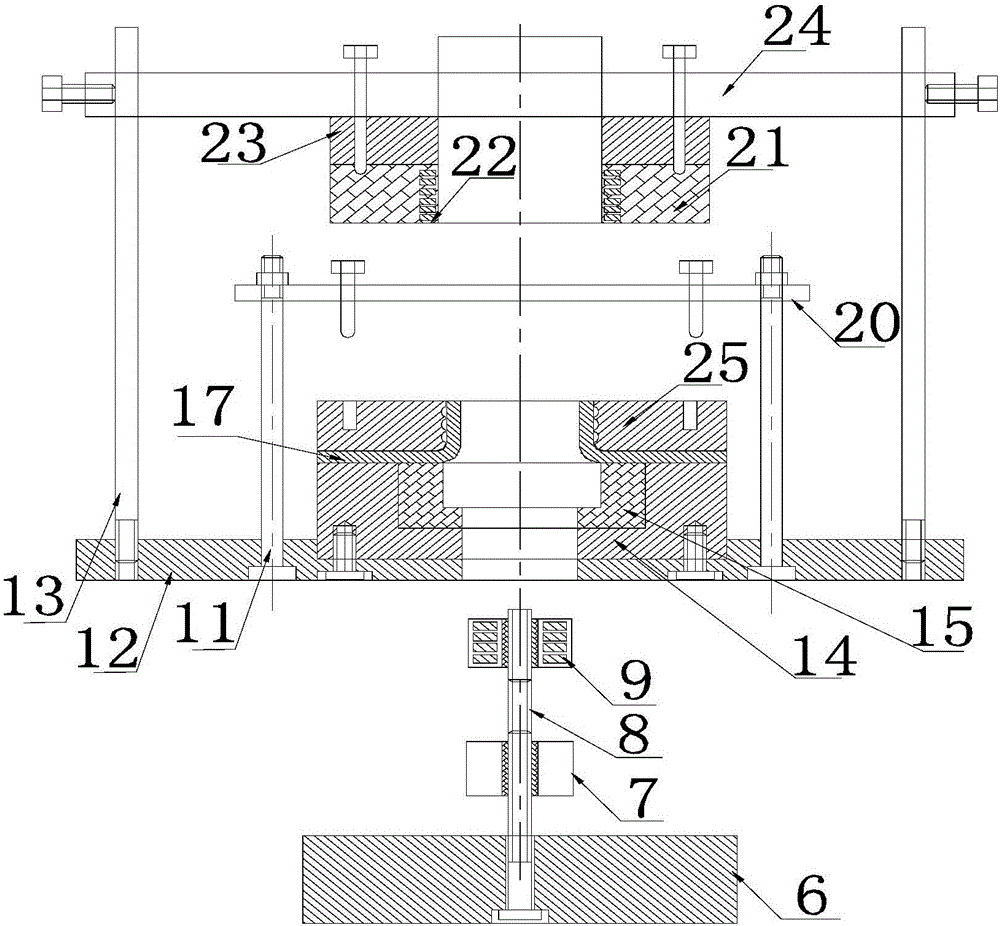

[0044] Specific implementation mode 1. Combination Figure 1 to Figure 10 Describe this embodiment, the method for connecting plates and pipes based on magnetic pulse forming described in this embodiment, the specific steps of the method are:

[0045] The step of punching the blank;

[0046] Step 1: Open a circular through hole in the center of the No. 2 base 12, and set up a positioning groove on the upper surface of the No. 2 base 12, install the lower molding plate 14 in the groove, and install the lower molding plate 14 in the cylindrical shape. A No. 1 insulating block 15 is installed in the structure to buffer the electromagnetic repulsion generated by the circular flat coil 16, and the circular flat coil 16 is arranged in the cylindrical structure of the No. 1 insulating block 15;

[0047] Step 2: Connect the positive and negative poles of the circular flat coil 16 to the positive and negative signal output terminals of the electromagnetic forming discharge system, and...

specific Embodiment approach 2

[0058] Embodiment 2. This embodiment is a further description of the method for connecting plates and pipes based on magnetic pulse forming described in Embodiment 1. Step 7 also includes installing one end of the telescopic rod 8 to the No. 1 base 6 through bolts. A step of.

[0059] The telescopic rod described in this embodiment realizes the transmission of the bulging coil and the transmission of the steel core bushing. The bolt cover surrounds the card slot to realize the fixation of the bulging coil and the steel core bushing at the designated position of the telescopic rod, and complete the transmission of the bulging coil during electromagnetic bulging and the transmission of the steel core bushing during electromagnetic connection.

specific Embodiment approach 3

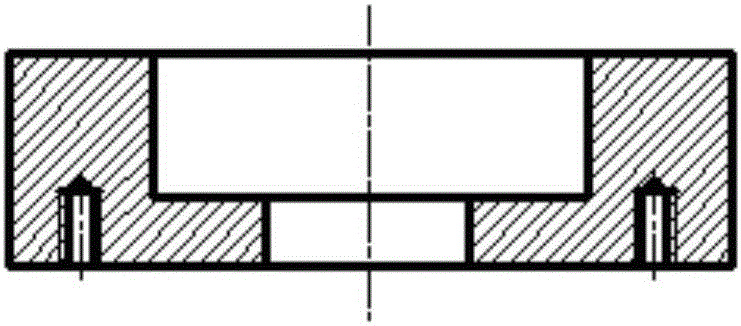

[0060] Specific Embodiment 3. This embodiment is a further description of the method for connecting plates and pipes based on magnetic pulse forming described in Embodiment 1. Step 8 also includes turning over the slab material 17 after corrugated bulging in Step 7. The side hole is heat treated, and the sub-step of surface derusting is carried out on the overlapping area of the flange hole.

[0061] The flanged hole after electromagnetic bulging described in this embodiment needs to meet a certain rigidity, so heat treatment is required to improve the strength and mechanical properties of the flanged hole. In addition, a steel mandrel is provided in the middle of the connection between the pipe fitting and the flanged hole cover to ensure that no structural instability occurs during the magnetic pulse connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com