A wheel rim inner support type spinning machine

A spinning machine and wheel rim technology, applied in the field of wheel rim forming, can solve the problems of irregular steel ring forming, affecting production efficiency, failure of rolling ring, etc., and achieve the effect of improving matching accuracy, increasing the rate of high-quality products in production, and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Attached below Figure 1-21 The present invention will be further described with specific embodiments.

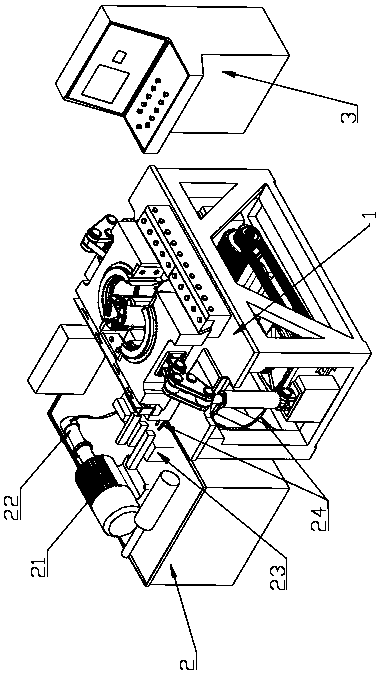

[0054] A rim inner support type spinning machine, comprising a spinning system 1, an oil supply system 2 and a control system 3.

[0055] Such as figure 1 As shown, the oil supply system 2 includes a motor 21, a hydraulic pump 22, an oil circuit control system 23, and an oil pipe 24. The hydraulic pump is driven by a motor, sucks oil from the hydraulic oil tank, forms pressure oil and discharges it, and sends it to the oil circuit control system Among them, the oil circuit control system 23 uses a solenoid valve to control the direction of the oil circuit in and out, and provides oil source for the radial movement power device 124 of the outer mold 121 and the oil channel in the rotating shaft 111 .

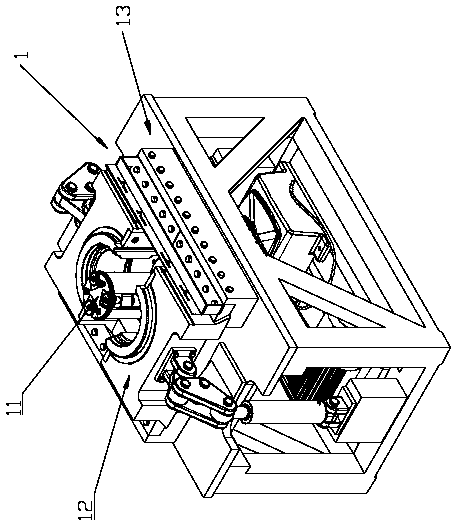

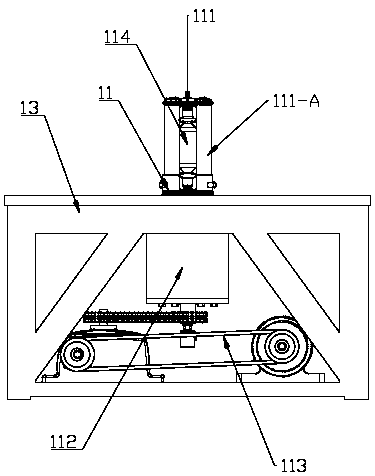

[0056] Such as figure 2 , 3 As shown, the spinning system 1 includes a rotating mechanism 11, and the rotating mechanism 11 includes a rotating shaft 111 verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com