Backwash rolling mill uniform fast-cooling header pipe

A cooling header and backwashing technology, which is applied to workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of uneven cooling, inability to cool quickly, poor cooling effect of steel plates, etc., and achieve simple structure, Excellent mechanical performance and rapid temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

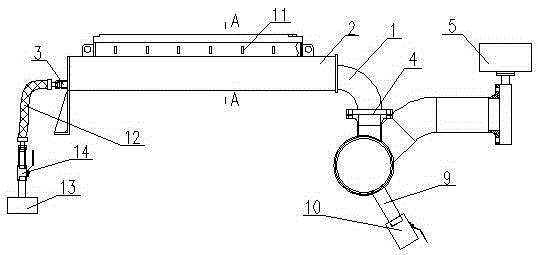

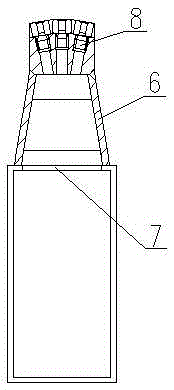

[0013] A uniform and fast cooling header for backwashing rolling mills, comprising a water inlet pipe 1 and a header body 2 connected to the water inlet pipe 1, the other end of the header body 2 is provided with a backwash port 3, and the water inlet pipe 1 The water inlet end is connected to the water inlet valve 5 through the water inlet flange 4, and a laminar flow cavity 6 is installed on the side wall of the header body 2, and the laminar flow cavity 6 and the header body 2 There are a number of overflow holes 7 evenly distributed on the side wall of the header main body 2, a number of evenly distributed nozzles 8 are provided on the laminar flow cavity 6, and the water inlet flange 4 passes through the sewage pipe 9 and the sewage valve. 10; the laminar flow cavity 6 is provided with a number of evenly distributed splitter plates 11; the backwash port 3 is connected to the backwash water source 13 through a rubber hose 12, and the rubber hose 12 is provided with Backwas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com