Recovery system for soot in boiler waste gas

A technology for recycling system and boiler waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problem of direct emission of waste gas to pollute the air, etc., and achieve the effect of low purification cost, avoidance of dust, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

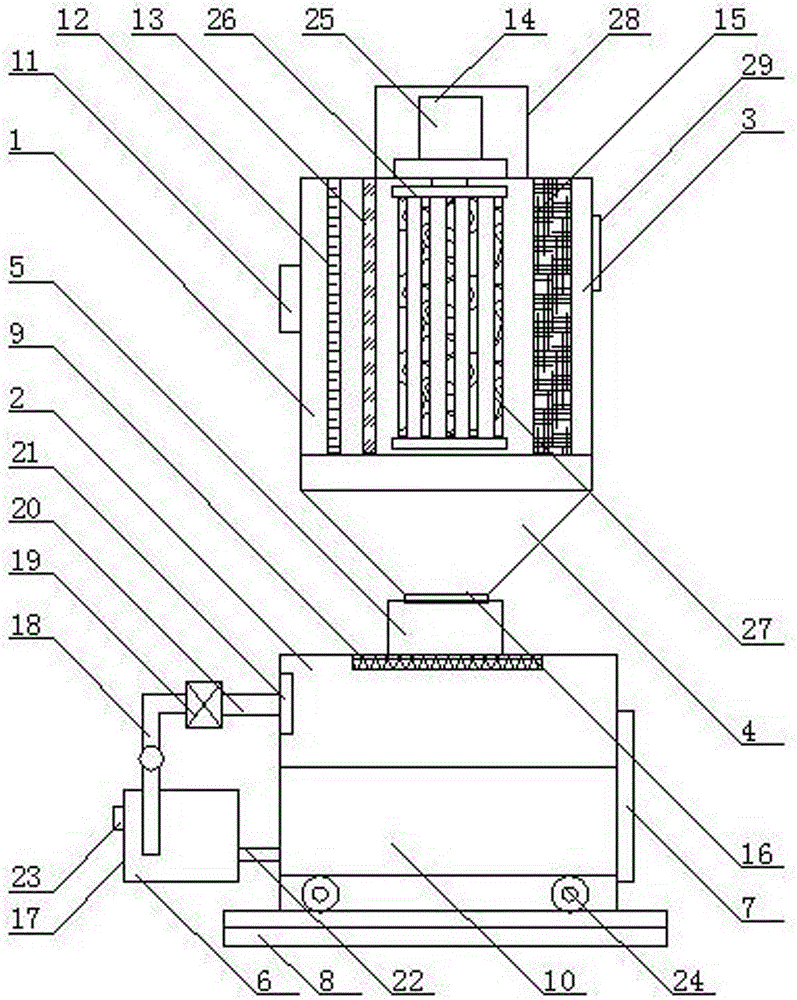

[0016] As shown in the figure, a smoke and dust recovery system in boiler exhaust gas includes a recovery system body, the upper end of the recovery system body is equipped with an electrostatic dust collection chamber 1, the lower end of the recovery system body is equipped with a smoke and dust recovery chamber 2, and the upper end of the electrostatic dust collection chamber 1 Install the dust collection bin 3, the lower end of the electrostatic dust collection chamber 1 is equipped with the ash collecting hopper 4, the bottom of the electrostatic dust collection chamber 1 is connected to the middle of the top of the dust recovery chamber 2 through the discharge pipe 5; the left side of the dust collection chamber 2 is equipped with an atomizing spray The shower device 6, the right side of the smoke recovery chamber 2 is equipped with a door 7, the bottom of the smoke recovery chamber 2 is equipped with a base 8, the top of the inside of the smoke recovery room 2 is equipped ...

Embodiment 2

[0023] Working principle: a system for recovering smoke and dust from boiler exhaust gas. The exhaust gas is passed into the electrostatic dust collection chamber 1 from the air inlet 11, filtered by the PP cotton filter 12 and the activated carbon filter 13 in turn, and then treated by the electrostatic dust collector 14. , collected by the dust collecting cloth plate 15, the purified exhaust gas is discharged through the air outlet 29, the smoke in the exhaust gas enters the ash collecting bucket 4, and enters the discharge pipe 5 from the ash outlet 16, and finally falls from the ash inlet net 9 into the dust collection box 10 at the bottom of the smoke and dust recovery chamber 2, and at the same time, the atomization spray device 6 is turned on, and the water pipe 18 quickly draws the water in the water tank 17 into the atomizer 19, and the atomized water flows from the atomization pipe 20 Enter the atomization outlet 21 and discharge through the atomization outlet 21. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com