Film coating premix for soft capsules and preparation method of film coating premix

A film coating and premix technology, which is used in capsule delivery, medical preparations with inactive ingredients, pharmaceutical formulations, etc., can solve the problems of damaged capsule skin, oil leakage, deformation, adhesion, etc., and achieves the effect of improving preservation. Technological progress is obvious, the effect of solving oral odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example is a health care product garlic essence soft capsule, which is filled with garlic essential oil, which emits some garlic smell.

[0028] Recipe one: IR 33%, hypromellose 30%, polyethylene glycol 7%, methacrylic acid-ethyl acrylate polymer 10%, talc 19.5%, soybean lecithin 0.5%.

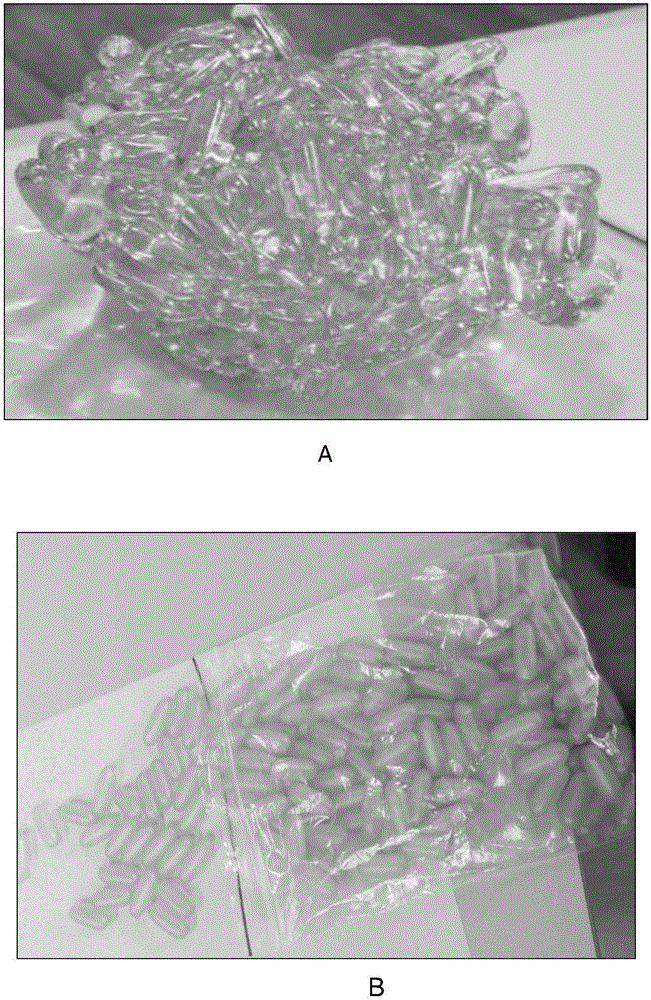

[0029] Depend on figure 1 It can be seen that the soft capsules that have been coated but not coated are all agglomerated during storage, and there is no agglomeration after two years of storage with coating, which solves the defects of soft capsules during storage and the odor in the mouth .

Embodiment 2

[0031] This example is an Omega 3 soft capsule product, which is filled with perilla oil and vitamins.

[0032] Recipe 2: IR 37%, hypromellose 24%, polyethylene glycol 16%, talc 22%, soybean lecithin 1%.

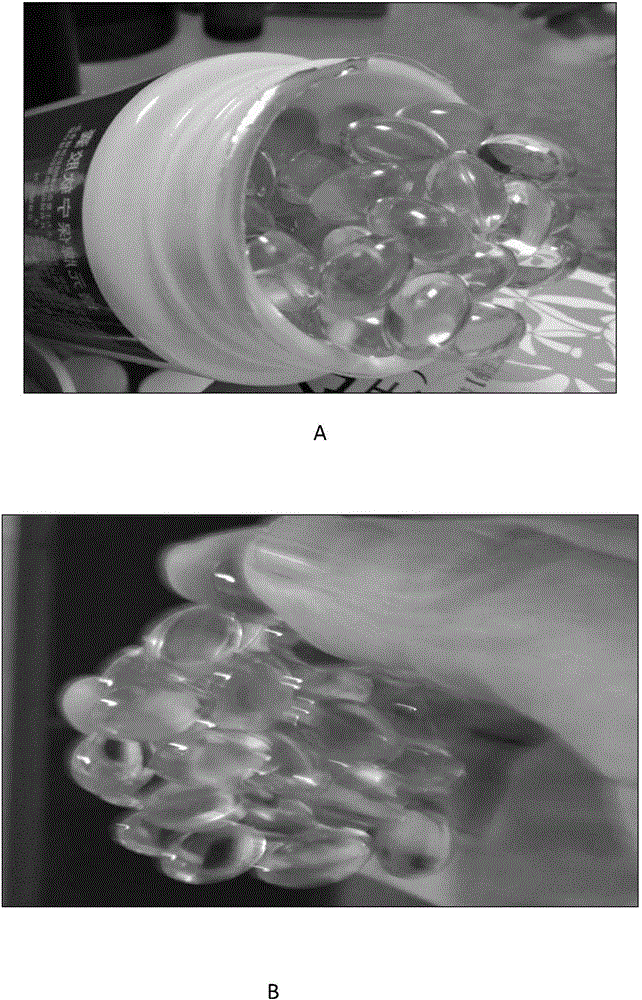

[0033] Depend on figure 2 It can be seen that uncoated products will produce clumping, adhesion, and seam cracking during consumption and use, giving people a sense of quality problems. These defects in the process of consumer use can be solved by coating.

Embodiment 3

[0035] In this example, the coating can be made into various colors to improve the appearance and grade of the product and solve the defects of preservation.

[0036] Recipe three: IR 38%, hypromellose 20%, polyethylene glycol 16%, colorant 1%, talcum powder 23.5%, soybean lecithin 1.5%.

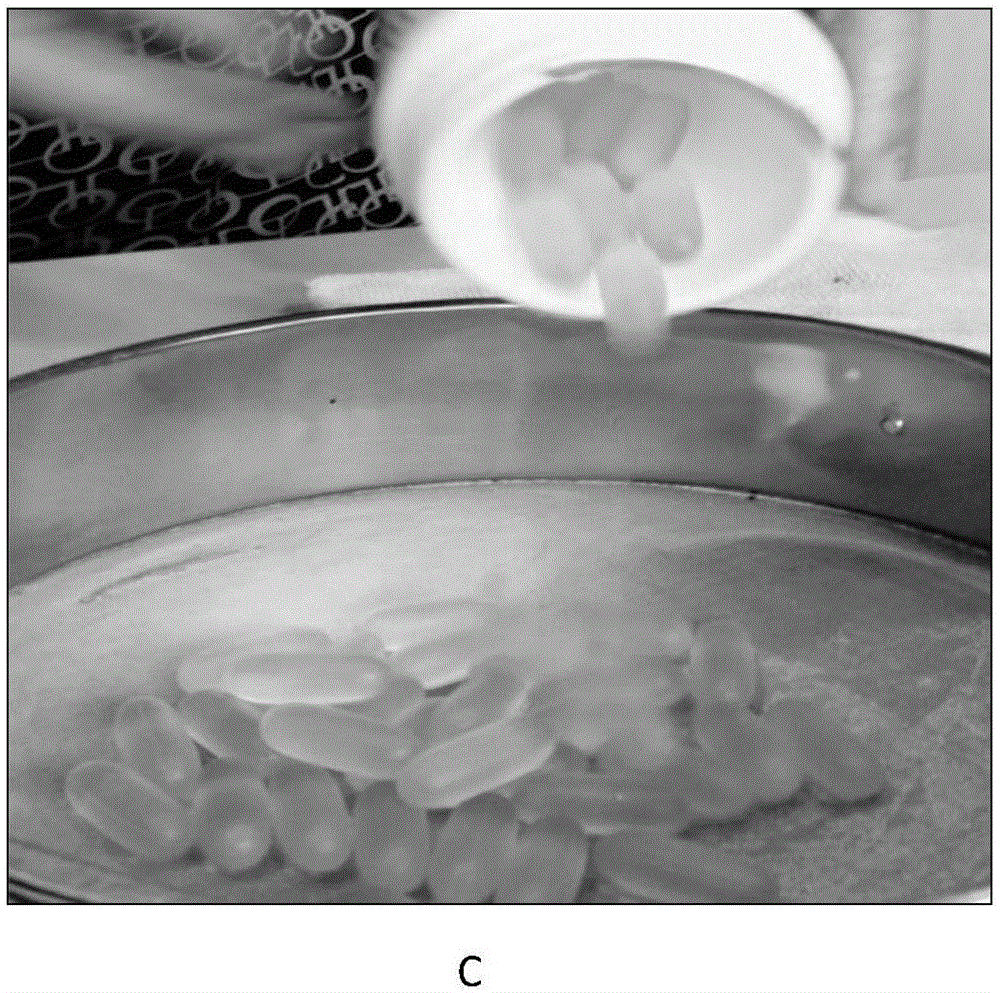

[0037] Depend on image 3 It can be seen that making soft capsules into various colors facilitates consumers to distinguish the types of drugs and facilitates storage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com