Manufacture method of bamboo shoot dietary fiber bean curds and product thereof

A technology of bamboo shoot dietary fiber and production method, applied in the field of food processing, can solve the problems of not meeting the requirements of dietary balance, lack of dietary fiber, etc., and achieve the effects of uniform color, high product quality and mild reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of bamboo shoot dietary fiber bean curd comprises the steps:

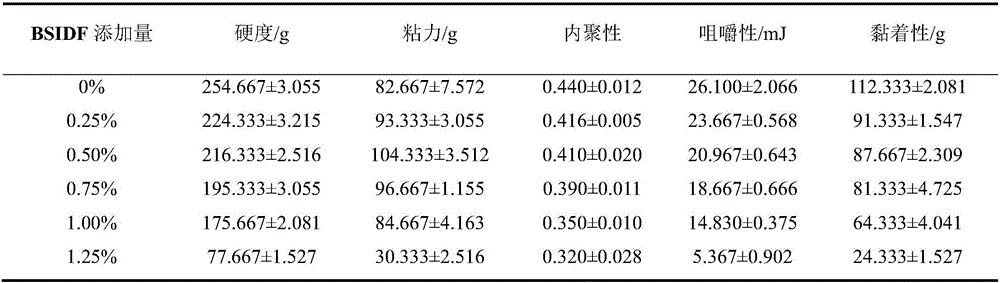

[0024] (1) Take 2 kg of fresh bamboo shoot raw material, remove the shell, cut it into sheets of 6 cm × 3 cm × 0.8 cm, blanch in boiling water for 10 min, drain, and then dry at 65 ° C for 20 h in a blast drying oven, Then pulverize with plant tissue masher and cross 80 mesh sieves to get bamboo shoots dietary fiber powder, the total dietary fiber content in the gained bamboo shoots dietary fiber powder is about 35%; gained bamboo shoots dietary fiber powder is hydrolyzed with compound enzyme, The compound enzyme is α-amylase, papain, and cellulase prepared according to the mass ratio of 3:1:1. When hydrolyzing, accurately weigh 50g of bamboo shoot dietary fiber coarse powder, add 2000mL of deionized water, and adjust the pH value of the solution. 5.5, add 0.5% compound enzyme mass fraction, hydrolyze at a temperature of 55°C for 90min, inactivate the enzyme at a temperature of 95°C fo...

Embodiment 2

[0028] The preparation method of bamboo shoot dietary fiber bean curd comprises the steps:

[0029](1) Take 5 kg of clear water bamboo shoot scraps, cut it into sheets of 8 cm × 2 cm × 0.5 cm, blanch in boiling water for 5 minutes, drain, and then dry at 60 °C for 24 hours in a blast drying oven, and then use The plant tissue masher is pulverized and crosses 70 mesh sieves to obtain the coarse meal of bamboo shoot dietary fiber, and the total dietary fiber content is about 37% in the meal of gained bamboo shoot dietary fiber; the meal of bamboo shoot dietary fiber gained in step a is hydrolyzed with compound enzyme, The compound enzyme is α-amylase, papain, and cellulase prepared according to the mass ratio of 3:1:1; when hydrolyzing, accurately weigh 100g of bamboo shoot dietary fiber coarse powder, add 4000mL of deionized water, and adjust the pH value of the solution 6.0, add 0.4% compound enzyme mass fraction, hydrolyze at 50°C for 60min, inactivate the enzyme at 95°C for ...

Embodiment 3

[0033] The preparation method of bamboo shoot dietary fiber bean curd comprises the steps:

[0034] (1) Take 10 kg of clear water bamboo shoot scraps, cut it into sheets of 7 cm × 2 cm × 0.5 cm, blanch in boiling water for 10 min, drain, and then dry at 70 °C for 18 h in a blast drying oven, and then use The plant tissue masher is pulverized and crosses a 60-mesh sieve to obtain the coarse powder of bamboo shoot dietary fiber, and the content of total dietary fiber in the obtained coarse powder of bamboo shoot dietary fiber is about 36%; The enzyme is α-amylase, papain, and cellulase prepared at a mass ratio of 3:1:1. During hydrolysis, accurately weigh 200g of bamboo shoot dietary fiber powder, add 8000mL of deionized water, and adjust the pH of the solution to 6.5 , add 0.6% compound enzyme mass fraction, hydrolyze at 70°C for 120 minutes, inactivate the enzyme at 95°C for 10 minutes after hydrolysis, filter with suction, wash with absolute ethanol for 3 to 5 times, dry and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com